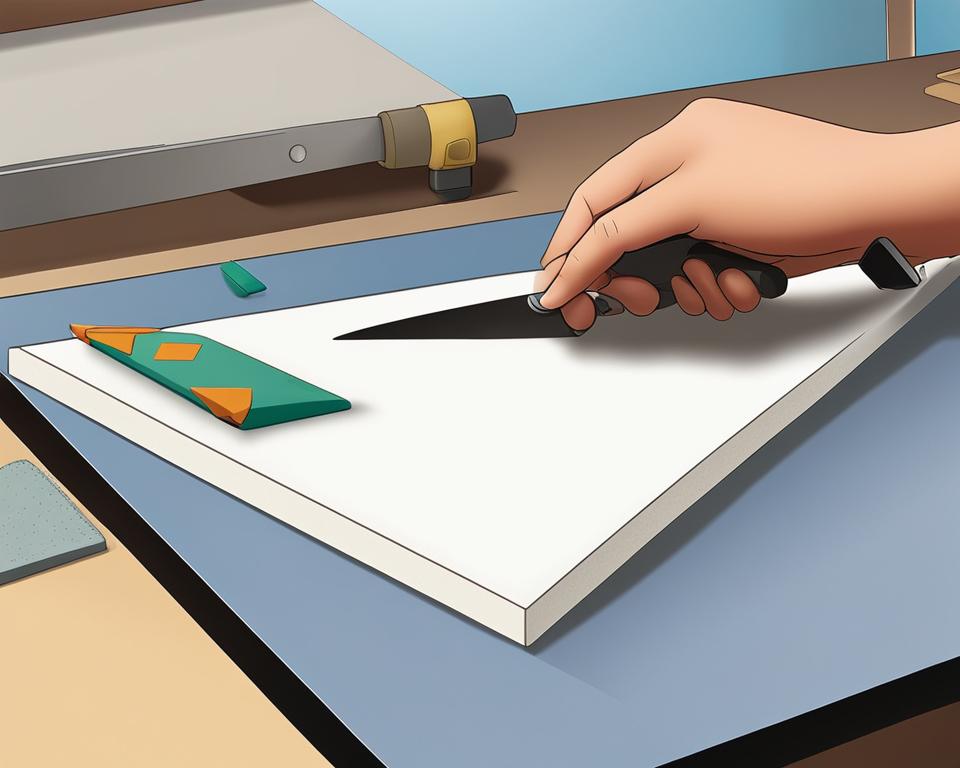

Cutting foam board can be a challenging task, but with the right techniques and tools, you can achieve clean and professional-looking edges. In this guide, we will provide step-by-step instructions on how to cut foam board effectively.

Key Takeaways:

- Learn how to cut foam board properly to achieve clean edges.

- Use the right tools, such as an X-ACTO knife or utility knife.

- Follow the best way to cut foam board: measure, mark, align, and make several passes.

- For cutting foam board circles, you can use a compass or a foam board circle cutter.

- Additional tips include measuring twice, using a straight edge, and trimming stray bits if necessary.

The Right Tool for Cutting Foam Board

When it comes to cutting foam board, having the right tools is essential for achieving clean and precise cuts. The two main tools recommended for this task are an X-ACTO knife or a utility knife with a fresh blade. These types of knives provide sharpness and control, allowing you to easily slice through the foam board without causing any damage.

Scissors, saws, and hot knives are not recommended for cutting foam board. Scissors can result in uneven and jagged edges, while saws may cause the foam board to crack or break. Hot knives, although effective for some materials, can melt the foam and leave behind messy and unsightly edges.

By using a sharp knife with a clean blade, you’ll be able to smoothly cut through foam board and achieve the desired shapes and sizes for your projects.

Table: Recommended Tools for Cutting Foam Board

| Tool | Description |

|---|---|

| X-ACTO Knife | A precision cutting tool with a fine, pointed blade that allows for accurate and controlled cuts. |

| Utility Knife | A versatile cutting tool with a retractable blade, perfect for cutting through foam board and other materials. |

Using the right tools is the first step towards achieving clean and professional-looking edges when cutting foam board. Make sure to always use a sharp and appropriate knife for the task at hand to ensure accurate and smooth cuts.

The Best Way to Cut Foam Board

When it comes to cutting foam board, following the right technique is essential to achieve clean and precise cuts. Here, we will outline the best way to cut foam board effectively, ensuring professional-looking results every time.

Step 1: Measure and Mark

Before making any cuts, start by measuring the desired size and marking it on the foam board using a pencil or marker. This will serve as your guide throughout the cutting process.

Step 2: Align and Secure

Next, align a straight edge, such as a ruler or T-square, along the marked line. Hold it firmly in place to ensure stability and accuracy during the cutting process.

Step 3: Start the Cut

Using a sharp utility knife or X-ACTO knife, start the cut by poking the tip of the blade into the top layer of the foam board. Take care not to apply too much pressure at once to prevent any tearing or jagged edges.

Step 4: Cut with Multiple Passes

Adjust the angle of the knife to be no more than 30 degrees from the surface of the board. Make several passes along the straight edge, cutting through the top layer of the foam board with each pass. This gradual approach ensures a clean and even cut.

Step 5: Trim if Necessary

Once the main cut is complete, inspect the edges for any stray bits of foam board. Use the knife or a pair of scissors to trim these if necessary, ensuring a smooth and neat finish.

By following these steps, you can confidently cut foam board with precision and achieve professional results. Remember to always prioritize safety and use the appropriate tools for the task at hand. Now let’s move on to cutting foam board circles in the next section.

The Best Way to Cut Foam Board Circles

When it comes to cutting foam board circles, there are a few methods you can use to achieve clean and precise results. Whether you’re working on a craft project or a professional presentation, these techniques will help you create perfect circles every time.

Method 1: Using a Compass

To start, mark the center of the circle on the foam board using a pencil. Then, take a compass and adjust it to the desired radius of your circle. Place the compass tip at the center mark and rotate it around to draw the circle on the foam board.

Next, take a sharp utility knife or X-ACTO knife and carefully cut along the pencil line, making multiple passes to cut through the layers of foam. Take your time and apply even pressure to ensure a smooth and precise cut.

Method 2: Using a Foam Board Circle Cutter

If you frequently need to cut foam board circles, investing in a foam board circle cutter can be a worthwhile option. This tool operates like a compass with a blade, making it easy to create circles of various sizes.

To use a foam board circle cutter, mark the center of the circle on the foam board and set the tool’s pivot point at the center mark. Then, rotate the blade around the circle, applying light pressure to cut through the foam board.

| Pros of using a compass: | Pros of using a foam board circle cutter: |

|---|---|

|

|

Choose the method that best suits your needs and preferences. Both the compass method and the foam board circle cutter offer reliable ways to cut foam board circles with precision and ease.

Tips for Cutting Foam Board

When it comes to cutting foam board, following some key tips can help you achieve precise and clean cuts. Whether you’re working on an art project, architectural rendering, or framing, these techniques will ensure professional-looking results. Here are some tips for cutting foam board:

- Measure Twice, Cut Once: Take accurate measurements and double-check them before making any cuts. This helps prevent mistakes and ensures that your final piece fits perfectly.

- Use a Straight Edge: Aligning a straight edge along your cutting line provides stability and helps you achieve straight cuts. You can use a ruler, a T-square, or even a piece of sturdy cardboard as a guide.

- Maintain a 30-Degree Angle: When using a knife or utility blade, keep the cutting edge at a 30-degree angle. This angle allows for smoother and cleaner cuts through the foam board.

- Make Multiple Passes: Instead of trying to cut through the foam board in one go, make multiple passes along the cutting line. This helps you maintain control and ensures a cleaner cut without tearing the foam.

- Trim Stray Bits: After making the initial cut, inspect your foam board for any stray bits or uneven edges. Use a knife or scissors to trim off any excess foam and achieve a neat finish.

By applying these tips, you’ll be able to cut foam board with ease and precision. Remember to work slowly and carefully, adjusting your technique as needed. With practice, you’ll develop a knack for cutting foam board like a pro.

Testimonial:

“Following these tips completely changed my experience with cutting foam board. I used to struggle with jagged edges and imprecise cuts, but now my projects look clean and professional. It’s amazing what a difference the right technique can make!”

– Samantha, Foam Board Enthusiast

Comparison Table: Foam Board Cutting Tools

| Tool | Pros | Cons |

|---|---|---|

| X-ACTO Knife | – Precise cuts – Easily replaceable blades |

– Requires steady hand – May require multiple passes |

| Utility Knife | – Versatile – Suitable for thicker foam boards |

– Can be more challenging to control – Blade may dull quickly |

| Hot Wire Cutter | – Cuts through foam like butter – Produces smooth edges |

– Requires extra caution due to heat – Limited to certain foam thicknesses |

| Scissors | – Great for softer foam boards – Easy to maneuver |

– May result in less precise cuts – Limited to thinner foam boards |

Cutting Foam Board with Scissors and Wax Blade

Cutting foam board with scissors can be a convenient option, especially when working with soft foam. To ensure a clean cut, trace your desired design or shape on the foam board using a permanent marker before cutting. This will serve as a guide for precise cutting. Use heavy-duty scissors and apply even pressure while cutting to avoid any jagged edges.

Another technique for achieving a smoother cut is by using a wax blade. To create a wax blade, simply rub a white candle along the cutting edge of a sharp blade. The wax helps to lubricate the cut and reduces friction, resulting in a cleaner and smoother edge. This method is particularly useful when working with thicker foam boards.

Tip: For intricate designs or detailed cuts, consider using small, sharp scissors or craft knives for more precise control.

Remember to always exercise caution and take your time when cutting foam board with scissors or a wax blade. It’s important to prioritize safety and wear appropriate protective gear, such as gloves, to avoid any injuries.

| Pros of Cutting Foam Board with Scissors | Cons of Cutting Foam Board with Scissors |

|---|---|

| – Convenient and easily accessible tool | – Limited control for intricate designs |

| – Can be used for both soft and rigid foam boards | – May result in jagged edges if not cut carefully |

| – Suitable for smaller projects or details | – Requires steady hand and precision |

In summary, cutting foam board with scissors or a wax blade can be a practical and effective method, depending on the type of foam board and desired cuts. Whether you’re working on a small project or need to achieve smoother edges, these techniques offer versatility and ease of use.

Cutting Foam Board with Cookie Cutters

For a creative and effective way to cut soft or rigid foam, you can use cookie cutters. This method allows you to easily create various shapes and designs in your foam board projects. Here’s how you can use cookie cutters to cut foam board:

- Place the foam board flat on your work surface.

- Select a metal cookie cutter in the desired shape.

- Press the cookie cutter evenly through the foam board.

- Apply firm and even pressure to ensure a clean cut.

- Gently remove the cookie cutter from the foam board.

This technique is ideal for creating decorative shapes or embellishments on foam board, such as stars, hearts, animals, letters, and more. It’s a fun and easy way to add a unique touch to your projects.

Keep in mind that cookie cutters with intricate designs may require additional pressure or multiple passes to cut through the foam board effectively. Experiment with different sizes and shapes to achieve the desired results.

Example:

“Using cookie cutters to cut foam board not only provides precise shapes, but also adds a touch of creativity to my crafting projects. It’s a simple and enjoyable method that allows me to create unique designs for various applications. Whether I’m working on art projects, party decorations, or educational displays, cookie cutters make cutting foam board both efficient and fun.” – Jane, Craft Enthusiast

By utilizing cookie cutters, you can easily achieve accurate and intricate shapes in your foam board without the need for complex measuring or cutting techniques. This method is especially useful for those who prefer a quick and effortless way to personalize their foam board creations.

| Pros | Cons |

|---|---|

| Easy and fun to use | Shapes may be limited to available cookie cutter designs |

| Allows for precise shapes and designs | Not suitable for large-scale or extensive cutting |

| Provides a unique touch to projects | May require additional pressure for intricate designs |

Overall, cutting foam board with cookie cutters is an excellent option for those looking to add a creative flair to their foam board projects. It’s a user-friendly method that produces clean and precise results, making it a popular choice among crafters, educators, and DIY enthusiasts alike.

Cutting Foam Board with Electric Tools

When it comes to cutting foam board, electric tools can be a game-changer. They provide efficiency and precision, making them ideal for cutting through thick or stiff foam boards. The three main electric tools commonly used for cutting foam board are the foam board electric knife, foam board saw, and hot wire cutter.

The Foam Board Electric Knife

The foam board electric knife is a versatile tool specifically designed for cutting foam board. It features a heated blade that effortlessly slices through the foam, creating smooth and precise cuts. The electric knife’s adjustable temperature settings allow you to control the cutting speed and prevent excessive heat, ensuring clean edges.

The Foam Board Saw

A foam board saw is another electric tool that can be used to cut foam boards. It resembles a handheld saw with a fine-toothed blade that effectively cuts through the material. The foam board saw is particularly useful when cutting foam boards of various thicknesses or when creating intricate shapes.

The Hot Wire Cutter

For more intricate cuts and shapes, the hot wire cutter is a popular choice. This tool uses a heated wire to melt through the foam board, resulting in clean and smooth edges. The hot wire cutter is especially effective for cutting foam board contours or complex designs.

When using electric tools to cut foam board, it’s essential to prioritize safety. Always follow the manufacturer’s instructions, wear protective gear such as goggles and gloves, and secure the foam board firmly to prevent any movement during cutting. With these precautions in place, you can confidently use electric tools to achieve professional-looking cuts in your foam board projects.

Safety Precautions and Equipment for Electric Cutting

When it comes to cutting foam board with electric tools, safety should always be a top priority. Here are some important safety precautions to keep in mind:

- Wear proper eye and face protection, such as safety goggles or a face shield, to protect yourself from flying debris or dust.

- Secure the foam board to your work surface using clamps or weights to prevent it from moving while cutting. This will ensure stability and accuracy.

- Follow the manufacturer’s instructions for the specific electric cutting tool you are using. This includes proper handling, maintenance, and usage guidelines.

- Keep your fingers and hands clear of the cutting path to avoid accidental contact with the tool’s blade or moving parts.

- Always unplug the electric tool when not in use or when changing blades or accessories.

When it comes to equipment for electric cutting, there are a few options available:

- Electric Knife: An electric knife designed for foam board cutting is a popular choice. It offers precise and controlled cutting, making it ideal for intricate designs or detailed cuts.

- Foam Saw: A foam saw with a serrated blade is another option. This type of saw is specifically designed to cut through foam board and provides clean and accurate cuts.

- Hot Wire Cutter: A hot wire cutter uses a heated wire to slice through foam board. It is particularly effective for cutting thick or dense foam boards.

By following safety precautions and using the appropriate electric cutting equipment, you can ensure a safe and successful foam board cutting experience.

Electric Cutting Safety Tips:

- Always work in a well-ventilated area to avoid inhalation of any fumes or dust particles created during the cutting process.

- Do not force the electric cutting tool through the foam board. Let the tool’s blade or wire do the work and guide it gently along the desired cutting path.

- Inspect the foam board for any potential hazards, such as foreign objects or embedded nails, before cutting. Remove these objects to prevent damage to the cutting tool.

- Regularly inspect the cutting tool’s blades or wire for any signs of wear or damage. Replace them as needed to ensure optimal cutting performance.

- Store electric cutting tools in a safe and secure location, out of reach of children or unauthorized individuals.

Remember, proper safety precautions and equipment are essential when using electric tools for foam board cutting. Following these guidelines will help you achieve accurate, clean cuts while minimizing the risk of injury.

Properties and Uses of Foam Boards

Foam boards possess several properties that make them a popular choice for various applications. They are lightweight, durable, and versatile, making them suitable for a wide range of uses in different industries and settings.

One of the key properties of foam boards is their lightweight nature. This makes them easy to handle and transport, especially in projects that require large quantities of board. Despite their lightness, foam boards are also sturdy and rigid, providing stability and support for different purposes.

The uses of foam boards are diverse and extensive. They are commonly used in art projects, providing a smooth surface for painting, drawing, or mounting artwork. Foam boards are also frequently used in marketing presentations and architectural renderings, where they serve as a backdrop or display material to showcase designs and concepts.

Furthermore, foam boards find applications in framing, mounting, and creating sets and props for theatrical productions or events. Their versatility extends to the printing industry, where they are used for digital and screen printing, thanks to their smooth surface that allows for accurate and high-quality prints.

Table: Common Uses of Foam Boards

| Industry/Setting | Applications |

|---|---|

| Art | Canvas for painting, mounting artwork, crafts |

| Marketing | Presentation displays, signage, posters |

| Architecture | Architectural models, renderings |

| Frame shops | Mounting artwork, framing |

| Theater/Events | Sets, props, backdrops |

| Printing | Digital and screen printing |

As demonstrated by the table, foam boards are utilized across various industries for a multitude of purposes, highlighting their adaptability and widespread appeal. Whether you need a reliable material for creative projects, professional presentations, or practical applications, foam boards offer a versatile solution with their unique properties.

Conclusion

Cutting foam board can be a challenging task, but with the right tools and techniques, it becomes much easier. By following the step-by-step instructions provided in this guide, you can achieve clean and professional cuts in your foam board projects.

One important aspect of cutting foam board is using the right tools. An X-ACTO knife or utility knife with a new blade is highly recommended for precise and clean cuts. Scissors, saws, and hot knives should be avoided as they can result in jagged edges or potential injuries.

To achieve the best results, it’s essential to measure accurately, use a straight edge, and hold it firmly in place. Keeping the angle of the knife at around 30 degrees and making multiple passes along the straight edge helps ensure clean cuts. Additionally, for cutting foam board circles, you can either use a compass or a foam board circle cutter.

Remember to always prioritize safety when cutting foam board, especially when using electric tools. Use proper protective gear and follow the manufacturer’s instructions. Taking your time and being patient will result in accurate and professional-looking cuts.

FAQ

What tools are best for cutting foam board?

The best tools for cutting foam board are X-ACTO knives or utility knives with new blades. Scissors, saws, and hot knives are not recommended.

How can I achieve clean edges when cutting foam board?

To achieve clean edges, measure and mark the desired cut, align a straight edge along the marked line, poke the knife into the foam board, and make several passes along the straight edge.

How do I cut foam board circles?

There are two methods for cutting foam board circles. You can use a compass to draw the circle and cut along the pencil line with a knife, or use a foam board circle cutter.

What are some tips for cutting foam board?

Always measure twice and cut once, use a straight edge, keep the knife angle at around 30 degrees, make multiple passes, and trim any stray bits if necessary.

Can I use scissors to cut soft foam?

Yes, you can use heavy-duty scissors to cut soft foam. Trace your design with a permanent marker before cutting for a clean cut, or wax the blade for smoother cutting.

How can I cut foam board with cookie cutters?

Place the foam board flat on your work surface and press a metal cookie cutter evenly through the foam to cut out the shape.

Can I use electric tools to cut foam board?

Yes, you can use electric tools such as an electric knife, foam saw, or hot wire cutter to cut foam board, especially for thicker or stiffer boards.

What safety precautions should I take when cutting foam board with electric tools?

Wear eye and face protection, secure the foam board to prevent movement, and follow the manufacturer’s instructions for the specific tool you are using.

What are the properties and uses of foam boards?

Foam boards are lightweight and durable, making them suitable for art projects, marketing presentations, architectural renderings, framing, mounting, sets and props, and digital and screen printing.