If you’re looking to connect PVC to copper pipes without welding, you’re in the right place. In this guide, we’ll walk you through the steps and best practices for a secure and long-lasting connection. Whether you’re a DIY enthusiast or a homeowner in need of a plumbing solution, this guide will provide you with the knowledge you need to join PVC and copper pipes seamlessly.

Key Takeaways:

- There are different methods for connecting PVC to copper pipes without welding, including compression fittings, push-fit fittings, and shark bite fittings.

- It’s important to clean and prepare both the PVC and copper pipes before making the connection.

- Choosing the appropriate fittings for the job is crucial to ensure a secure and watertight seal.

- Follow the proper steps, including shutting off the water supply, testing for leaks, and making necessary adjustments or repairs.

- DIY PVC and copper plumbing can be a cost-effective and rewarding project with the right tools and know-how.

How to Connect PVC to Copper Plumbing Without Welding

When it comes to connecting PVC to copper plumbing without welding, there are several methods available that provide secure and reliable connections. Whether you’re a DIY enthusiast or a professional plumber, these techniques can help you achieve a watertight seal between PVC and copper pipes.

Compression Fittings

One popular method is to use compression fittings for the connection. These fittings utilize a nut and a ferrule to create a tight seal between the PVC and copper pipes. To connect the pipes using compression fittings, follow these steps:

- Measure and cut the PVC and copper pipes to the desired length.

- Slide the compression nut onto the copper pipe, followed by the ferrule.

- Insert the PVC pipe into the compression fitting.

- Tighten the compression nut with a pipe wrench, ensuring a secure connection.

Compression fittings provide a durable and long-lasting connection, and they are compatible with both PVC and copper pipes.

Push-Fit Fittings

Another method for connecting PVC to copper plumbing is using push-fit fittings. These fittings have a collet mechanism that securely holds the pipes in place without the need for any additional tools. Here’s how to connect PVC and copper pipes using push-fit fittings:

- Cut the PVC and copper pipes to the required length.

- Ensure the pipe ends are clean and free from burrs.

- Push the PVC and copper pipes completely into the push-fit fitting until they stop.

Push-fit fittings provide a quick and convenient connection method, making them ideal for DIY projects or situations where time is of the essence.

Shark Bite Fittings

For those looking for a versatile and easy-to-use option, shark bite fittings are an excellent choice. These fittings can connect PVC and copper pipes without soldering or using glue. Here’s how to use shark bite fittings for PVC to copper connection:

- Cut the PVC and copper pipes to the appropriate length.

- Clean the pipe ends and ensure they are free from debris.

- Push the PVC and copper pipes into the shark bite fitting until they reach the depth mark.

Shark bite fittings not only simplify the connection process but also allow for quick disassembly if needed.

Regardless of the method you choose, it’s crucial to follow the manufacturer’s instructions and ensure a watertight seal. Regularly check for leaks after making the connection to confirm its integrity.

Steps for Connecting PVC to Copper

When it comes to connecting PVC to copper pipes, following the right steps is crucial to ensure a secure and watertight connection. By using the appropriate tools and fittings, you can successfully join these two types of pipes without the need for welding. Here are the steps to connect PVC to copper pipes:

- Shut off the water supply at the main supply valve and the in-line valve to avoid any water flow during the connection process.

- Clean both the PVC and copper pipes thoroughly to remove any debris or dirt that may hinder the connection. You can use a pipe cleaner or a mild detergent to clean the pipes.

- Apply primer to both the PVC and copper pipes. This will help improve the adhesion between the pipes and fittings, ensuring a stronger connection.

- Choose the appropriate fittings for the job. Compression fittings and push-fit fittings are commonly used for PVC to copper connections. These fittings provide a secure and reliable connection.

- Insert the PVC pipe into the fitting, making sure it goes all the way in. Use a pipe wrench or pliers to tighten the fitting and secure the PVC pipe in place.

- Insert the copper pipe into the fitting, following the manufacturer’s instructions. Tighten the fitting using a pipe wrench or pliers, making sure it forms a tight seal with the copper pipe.

- Once the connection is complete, turn on the water supply and check for any leaks. Inspect the connection carefully for any signs of water or moisture. If you notice any leaks, make the necessary adjustments or repairs to ensure a watertight seal.

Connecting PVC to copper pipes may seem daunting, but by following these steps and using the right tools and fittings, you can achieve a successful connection. Remember to take the necessary precautions, such as shutting off the water supply, and double-check the connection for leaks. With proper installation, your PVC to copper connection can provide a reliable and long-lasting plumbing solution.

Best Practices for PVC to Copper Connection

When connecting PVC to copper, it’s important to follow a few best practices to ensure a successful and long-lasting connection.

- Choose the appropriate fittings: Use fittings specifically designed for connecting PVC to copper, such as compression fittings or push-fit fittings. These fittings provide a secure and watertight seal.

- Clean and prepare the pipes: Before making the connection, clean both the PVC and copper pipes to remove any debris. Apply primer to ensure a proper bond between the pipes.

- Test for leaks: After making the connection, it’s crucial to test for leaks. Turn on the water supply and check for any signs of water leakage. Make any necessary adjustments or repairs to ensure a watertight seal.

By following these best practices, you can ensure a successful PVC to copper connection for your plumbing needs.

Comparison of PVC to Copper Connection Methods

| Connection Method | Pros | Cons |

|---|---|---|

| Compression Fittings | Easy to install, provides a secure connection, reusable | Requires the use of a pipe wrench and pliers, slightly more expensive |

| Push-Fit Fittings | No tools required, quick and easy installation | May require more space for installation, not reusable |

| Shark Bite Fittings | No soldering or glue required, compatible with various pipe materials | Can be more expensive, may require additional support for larger pipes |

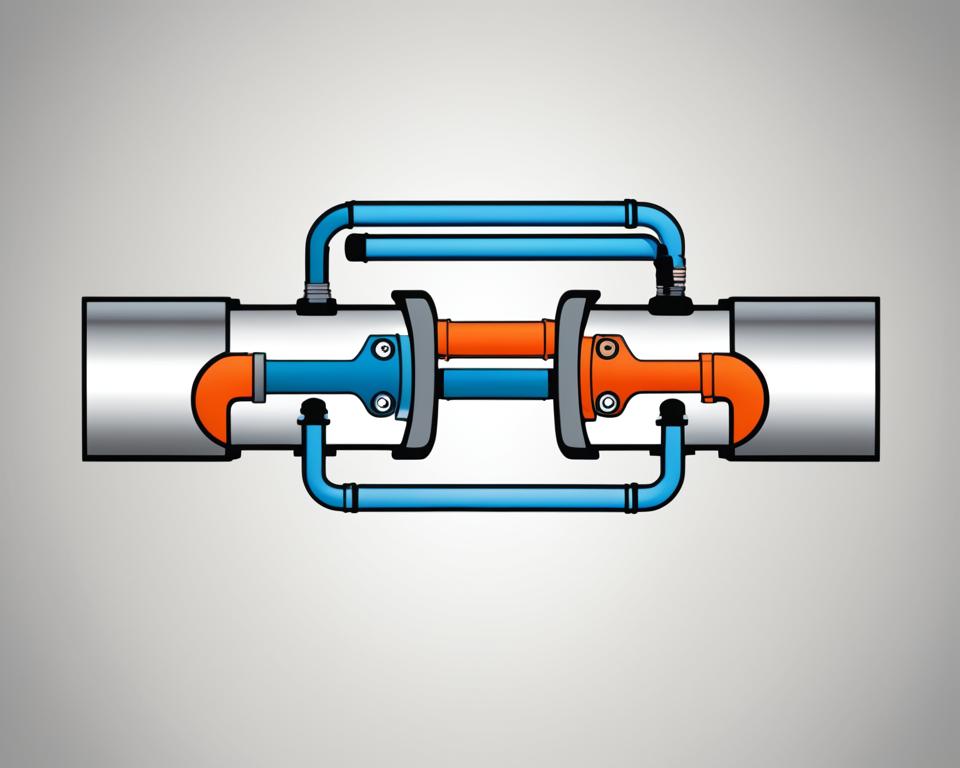

For a visual representation of the best practices, refer to the image above.

Remember, when connecting PVC to copper, it’s essential to use the proper fittings, clean and prepare the pipes, and test for leaks. Following these best practices will help you achieve a secure and reliable connection for your DIY PVC and copper plumbing projects.

PVC to Copper Adapter

A PVC to copper adapter is a fitting that allows for the connection of PVC and copper pipes. This adapter is specifically designed to provide a secure and watertight seal when joining these two types of pipes. Available in various sizes to accommodate different pipe diameters, the PVC to copper adapter can be easily installed using basic plumbing tools.

To ensure a successful connection, it is important to follow the manufacturer’s instructions and use the appropriate size of adapter for your pipes. This will help prevent leaks and ensure a proper fit. By using a PVC to copper adapter, you can seamlessly connect PVC and copper pipes without the need for welding or complex plumbing techniques.

When using a PVC to copper adapter, it is recommended to clean and prepare the pipes before installation. This includes removing any debris or dirt that may interfere with the connection. Once the pipes are clean, simply insert the PVC pipe into one end of the adapter and the copper pipe into the other end. Tighten the connections using a pipe wrench or pliers until they are secure.

It is always a good practice to test the connection for leaks once the installation is complete. Turn on the water supply and check for any signs of water leakage around the adapter. If any leaks are detected, make sure to tighten the connections further or consult a professional plumber for assistance.

Using a PVC to copper adapter is an effective and reliable method for connecting PVC and copper pipes. It provides a durable and leak-free joint, allowing for smooth water flow in plumbing systems. Whether you are working on a DIY plumbing project or need to make repairs, a PVC to copper adapter is a valuable tool to have on hand.

DIY PVC and Copper Plumbing

DIY PVC and copper plumbing can be a cost-effective and rewarding project for homeowners. By following the proper steps and using the right materials, it’s possible to make a secure and watertight connection between PVC and copper pipes.

There are various options available for connecting PVC to copper without the need for welding. One popular method is using compression fittings, which provide a tight seal and can be easily installed with basic plumbing tools like a pipe wrench and pliers. Another option is to use push-fit fittings, which offer quick and tool-free connections. Shark bite fittings are also a reliable choice as they eliminate the need for soldering or glue and can be used with different pipe materials.

Before making the connection, it’s crucial to clean and prepare the pipes. This involves removing any debris and applying primer to ensure a proper bond. Once the pipes are ready, choose the appropriate fittings for the job, ensuring they are compatible with both PVC and copper pipes.

After connecting the PVC and copper pipes, it’s important to test for leaks. Turn on the water supply and check for any signs of water leakage. Make any necessary adjustments or repairs to ensure a watertight seal.

To provide a visual representation, here is a table highlighting the different options for connecting PVC to copper pipes:

| Connection Method | Description |

|---|---|

| Compression Fittings | Requires tools like a pipe wrench and pliers to create a secure connection. Ideal for tight spaces. |

| Push-Fit Fittings | Allows for quick and easy connections without the need for tools. Suitable for DIY projects. |

| Shark Bite Fittings | Offers versatile compatibility with different pipe materials. No soldering or glue required. |

With the right tools and a little bit of know-how, DIY PVC and copper plumbing can be a successful venture. Remember to always follow the manufacturer’s instructions and prioritize safety when working with plumbing systems.

Conclusion

Connecting PVC to copper pipes can be easily achieved without the need for welding. By utilizing compression fittings, push-fit fittings, or shark bite fittings, homeowners can create a secure and watertight connection between these two types of pipes. It is crucial to follow the proper steps, clean, and prepare the pipes, as well as select the appropriate fittings to ensure a successful connection. With the right tools and a little bit of DIY knowledge, homeowners can confidently embark on PVC to copper plumbing projects.

The process of connecting PVC to copper involves choosing the right fittings for the job, whether it be compression fittings, push-fit fittings, or shark bite fittings. These fittings offer an easy and reliable way to join PVC and copper pipes, without the need for complex welding techniques. When following the proper steps, cleaning and preparing the pipes, and using the correct fittings, homeowners can create a secure and long-lasting connection for their water lines.

In summary, connecting PVC to copper is a straightforward task that can be accomplished by DIY enthusiasts. By understanding the different types of fittings available and following the necessary steps, homeowners can confidently undertake PVC to copper plumbing projects. Whether it’s for a small repair or a larger installation, with the right tools and a little bit of know-how, you can successfully join PVC and copper pipes, creating a reliable and efficient water line system.

FAQ

How do I connect PVC to copper plumbing without welding?

You can connect PVC to copper plumbing without welding by using compression fittings, push-fit fittings, or shark bite fittings. These fittings, along with basic plumbing tools, allow for a secure and long-lasting connection.

What are the steps for connecting PVC to copper pipes?

The steps for connecting PVC to copper pipes are as follows: shut off the water supply, clean and prepare the pipes, choose the appropriate fittings, insert the pipes into the fittings, test for leaks, and make any necessary adjustments or repairs.

What are the best practices for PVC to copper connection?

When connecting PVC to copper, it’s important to use the appropriate fittings, clean and prepare the pipes, and test the connection for leaks. Following these best practices will ensure a successful and long-lasting connection.

What is a PVC to copper adapter?

A PVC to copper adapter is a fitting that allows for the connection of PVC and copper pipes. It provides a secure and watertight seal and is available in different sizes to accommodate various pipe diameters.

Can I do DIY PVC and copper plumbing?

Yes, DIY PVC and copper plumbing can be a cost-effective and rewarding project for homeowners. By following the proper steps and using the right materials, it’s possible to make a secure and watertight connection between PVC and copper pipes.