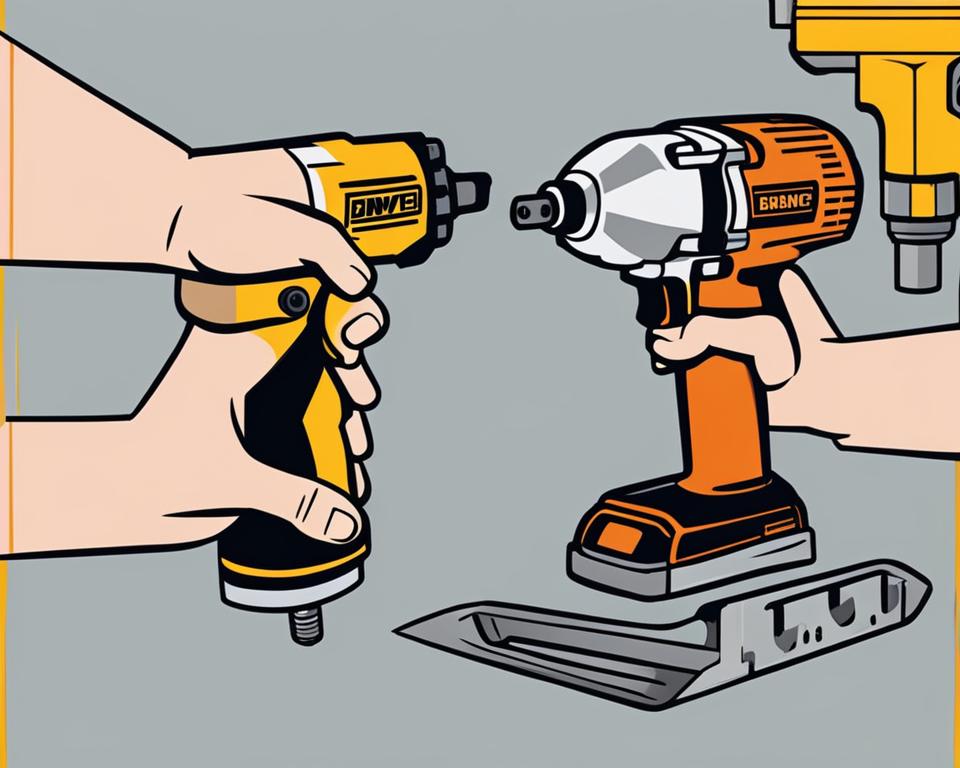

An impact driver and an impact wrench may seem similar at first glance, but they serve different purposes in the world of power tools. Understanding the differences between these two tools is crucial for choosing the right one for your specific needs.

Firstly, an impact driver is designed for fastening screws and other fasteners that require a driver bit. It features a 1/4-inch hex collet and is compatible with various types of fasteners, including slotted, Phillips, square, Torx, and more. On the other hand, an impact wrench is primarily used for fastening and loosening nuts and bolts. It typically utilizes a square drive that accepts a socket.

When it comes to size and weight, impact drivers are more compact and lightweight compared to impact wrenches. Due to their smaller size, impact drivers are commonly used for home projects, woodworking, and general DIY tasks. Impact wrenches, on the other hand, come in a range of sizes and performance levels, making them suitable for heavy-duty applications such as automotive work.

In terms of drive styles, impact drivers use a 1/4-inch hex collet, while impact wrenches typically use a square drive. This difference allows impact drivers to offer greater versatility in terms of available styles, including standard pistol grip and right angle options. Impact wrenches, on the other hand, encompass a wider range of styles and performance levels, including pistol grip, stubby, right angle, ratchet, and utility impact wrenches.

One of the key factors to consider when choosing between an impact driver and an impact wrench is the specific task at hand. Impact drivers excel at screwdriving and drilling, making them ideal for tasks that require precision and control. On the other hand, impact wrenches are best suited for heavy-duty applications that involve fastening or loosening nuts and bolts, providing higher levels of torque and power.

To sum it up, the difference between an impact driver and an impact wrench lies in their intended uses, size, drive styles, and levels of torque. By understanding these distinctions, you can select the right tool for your specific needs and ensure optimal performance in your projects.

Key Takeaways:

- An impact driver is used for screwdriving fasteners, while an impact wrench is used for fastening and loosening nuts and bolts.

- Impact drivers are more compact and lightweight, making them suitable for home use and woodworking.

- Impact wrenches come in a range of sizes and performance levels, and are commonly used for heavy-duty tasks.

- Impact drivers use a 1/4-inch hex collet, while impact wrenches typically use a square drive.

- Consider the specific task at hand when choosing between an impact driver and an impact wrench.

Impact Driver vs Impact Wrench: Drive Styles and Power Sources

When comparing impact drivers and impact wrenches, one of the key factors to consider is their drive styles. Impact drivers use a 1/4-inch hex collet, allowing them to accommodate various driver bit sizes. This makes them ideal for tasks that require screwdriving and drilling, such as assembling furniture or hanging shelves. On the other hand, impact wrenches typically feature a square drive that accepts sockets. This design enables them to tackle heavy-duty applications, including automotive repairs and construction projects.

Impact drivers come in different styles, such as standard pistol grip and right angle options. This versatility allows users to choose the best option based on their specific needs. Impact wrenches, on the other hand, offer a wider range of styles and performance levels. These include pistol grip, stubby, right angle, ratchet, and utility impact wrenches. The variety of options ensures that there is an impact wrench suitable for every job, whether it involves tightening bolts or removing stubborn nuts.

In terms of power sources, both impact drivers and impact wrenches can be either corded or cordless. Corded models are powered by electricity, providing consistent and reliable performance. Cordless models, on the other hand, are powered by rechargeable batteries, allowing for greater mobility and convenience. The choice between corded and cordless options depends on the specific requirements of the task and the user’s preference for portability versus continuous power supply.

Summary:

- Impact drivers use a 1/4-inch hex collet, while impact wrenches typically have a square drive that accepts sockets.

- Impact drivers come in various styles, including pistol grip and right angle options, while impact wrenches offer a wider range of styles and performance levels.

- Both impact drivers and impact wrenches can be corded or cordless, providing users with options based on their specific needs and preferences.

Difference Between Using an Impact Driver and Impact Wrench

When it comes to using an impact driver versus an impact wrench, understanding their specific applications is key. While both tools share similarities in terms of their impact mechanism, they are designed for different purposes.

An impact driver is primarily used for fasteners that require a driver bit, such as screws with slotted, Phillips, square, or Torx heads. It is an excellent choice for driving screws quickly and efficiently, making it a popular tool for construction projects, furniture assembly, and general DIY tasks. Impact drivers are known for their high rotational force and impressive torque, allowing them to handle a wide variety of fasteners with ease.

On the other hand, an impact wrench is specifically designed for hex head fasteners like nuts and bolts or timber screws. It uses a socket to grip and apply torque to the fastener, making it an indispensable tool in automotive repair, heavy equipment maintenance, and construction. Impact wrenches come in various sizes and power levels, from compact models suitable for home use to heavy-duty options used in professional settings.

It’s important to use the right tool for the job to ensure optimal performance and prevent damage to both the fasteners and the tool itself.

Comparison of Using an Impact Driver and Impact Wrench

To better understand the differences between using an impact driver and impact wrench, let’s take a look at a side-by-side comparison:

| Factor | Impact Driver | Impact Wrench |

|---|---|---|

| Primary Fasteners | Slotted, Phillips, square, Torx screws | Hex head fasteners (nuts, bolts, timber screws) |

| Tool Type | Screwdriver and drill | Fastener fastening and loosening |

| Application | Construction, woodworking, general DIY | Automotive repair, heavy equipment maintenance, construction |

| Torque | High rotational force, suitable for various fasteners | Higher torque ranges, specifically for fastening and loosening nuts and bolts |

| Size and Weight | Compact and lightweight | Varies in size and weight, depending on the model |

As seen in the comparison table, the choice between using an impact driver or an impact wrench depends on the specific task at hand. While an impact driver is versatile and ideal for general use, an impact wrench provides the necessary power and torque for heavy-duty applications. By understanding their differences and unique capabilities, you can select the tool that best suits your needs and achieve optimal results.

Impact Driver vs Impact Wrench: Torque and Speed Differences

When comparing impact drivers and impact wrenches, one of the key differences lies in their torque and speed capabilities. Understanding these differences is crucial in determining which tool is most suitable for your specific needs.

Torque

Impact wrenches are known for their impressive torque output, making them ideal for heavy-duty applications such as automotive work. These powerful tools typically provide torque starting around 100 ft-lbs and can go well over 1000 ft-lbs. In contrast, impact drivers tend to have lower torque ratings, often exceeding 2000 in-lbs. While impact drivers may not have the same level of torque as impact wrenches, they offer sufficient power for professional use and general DIY projects.

Speed

In terms of speed, impact drivers and impact wrenches also have notable differences. Impact drivers are designed for high-speed fastening and drilling tasks, allowing for quick and efficient work. On the other hand, impact wrenches prioritize torque over speed, making them ideal for tasks that require high rotational force, such as removing stubborn nuts and bolts.

To summarize, impact wrenches offer higher torque and are better suited for heavy-duty applications, while impact drivers excel in speed and versatility. Both tools have their own strengths and should be chosen based on the specific requirements of the task at hand.

| Impact Driver | Impact Wrench | |

|---|---|---|

| Torque | Exceeds 2000 in-lbs | Starts around 100 ft-lbs and can go well over 1000 ft-lbs |

| Speed | High-speed fastening and drilling | Prioritizes torque over speed |

| Application | Professional use, general DIY projects | Heavy-duty tasks such as automotive work |

By considering the torque and speed differences between impact drivers and impact wrenches, you can make an informed decision on which tool is best suited for your specific needs. Whether you require the speed and versatility of an impact driver or the high torque of an impact wrench, choosing the right tool will ensure efficient and effective completion of your tasks.

Impact Driver vs Impact Wrench: Size and Power Source

When comparing impact drivers and impact wrenches, one of the key differences to consider is their size. Impact drivers are designed to be compact and lightweight, making them easy to maneuver and ideal for tasks that require precision and control. On the other hand, impact wrenches can be bulkier and heavier, especially when considering cordless options with higher power levels. This is because impact wrenches are built to handle heavier-duty applications, such as automotive work and industrial tasks, where a larger tool may be necessary for increased torque and power.

In terms of power source, both impact drivers and impact wrenches can be found in corded and cordless versions. Cordless options are popular due to their portability and convenience, allowing for unrestricted movement and use in various locations. Impact drivers are often powered by rechargeable lithium-ion batteries, which provide ample power and long runtimes. Impact wrenches, especially those used in industrial settings, can be powered by pneumatic (air-powered) systems or high-capacity batteries for maximum performance.

| Impact Driver | Impact Wrench | |

|---|---|---|

| Size | Compact and lightweight | Bulkier and heavier |

| Power Source | Rechargeable lithium-ion battery | Corded, cordless (battery or pneumatic) |

Overall, the size and power source of impact drivers and impact wrenches play a significant role in their suitability for different tasks. Impact drivers, with their compact size and lightweight design, are often favored for home use, woodworking, and DIY projects. Their cordless nature allows for easy maneuverability and use in tight spaces. Impact wrenches, on the other hand, excel in heavy-duty applications and are commonly used in automotive and industrial settings where the extra power and larger size are necessary to tackle tough jobs.

Conclusion

In conclusion, the main difference between impact drivers and impact wrenches lies in their intended uses. Impact drivers are specialized for screwdriving and drilling tasks, while impact wrenches are designed for fastening and loosening nuts and bolts.

Impact drivers are more compact and lightweight, making them suitable for home use and woodworking. They are ideal for tasks that require precision and finesse, such as assembling furniture or installing cabinets.

On the other hand, impact wrenches are commonly used for heavy-duty tasks in automotive and industrial settings. They provide higher levels of torque and are capable of tackling tough bolts and fasteners. Whether it’s changing tires or working on construction sites, impact wrenches are built to handle the rigors of demanding applications.

When choosing between an impact driver and an impact wrench, it’s important to consider the specific application. Both tools offer different levels of torque and speed, so selecting the right tool for the job is crucial for optimal performance and efficiency.

FAQ

What is the difference between an impact driver and an impact wrench?

An impact driver is used for fasteners with a head that requires a driver bit, such as screws with slotted, Phillips, square, or Torx heads. An impact wrench, on the other hand, is used for fastening and loosening nuts and bolts.

What drive style do impact drivers and impact wrenches use?

Impact drivers use a 1/4-inch hex collet, while impact wrenches typically use a square drive that accepts a socket.

Can impact drivers be used for hex head fasteners?

Yes, impact drivers can be used for hex head fasteners with the use of socket adapters and nut driver bits. However, it is important to use the right tool for the application to avoid damaging the fasteners or the tool itself.

Are impact drivers more compact and lightweight than impact wrenches?

Yes, impact drivers are typically more compact and lighter than impact wrenches, especially cordless impact wrenches. Pneumatic impact wrenches can be lighter than impact drivers due to their simplicity and lack of a motor.

Which tool provides more power, an impact driver or an impact wrench?

Impact wrenches generally provide more power compared to impact drivers. Impact drivers can have torque exceeding 2000 in-lbs, while impact wrenches can start around 100 ft-lbs and go well over 1000 ft-lbs.

What are impact drivers and impact wrenches commonly used for?

Impact drivers are commonly used for home use, woodworking, and general DIY projects. Impact wrenches are often used for heavy-duty tasks, such as automotive work and industrial applications.