Welcome to our in-depth exploration of the history of fracking, also known as hydraulic fracturing. In this guide, we will delve into the evolution of fracking techniques, the hydraulic fracturing process, and the timeline of fracking history. Whether you’re new to the subject or seeking a deeper understanding, we’ve got you covered.

Key Takeaways:

- Fracking is a technique used to extract natural gas or oil from tight rock formations.

- The process dates back to the 1860s and has undergone significant advancements over time.

- Fracking involves injecting fluid at high pressures to create fractures and release trapped resources.

- Advancements in fracking fluid and horizontal drilling techniques have led to industry growth.

- Regulations and ongoing research are necessary to address environmental and health concerns.

Fracking Techniques

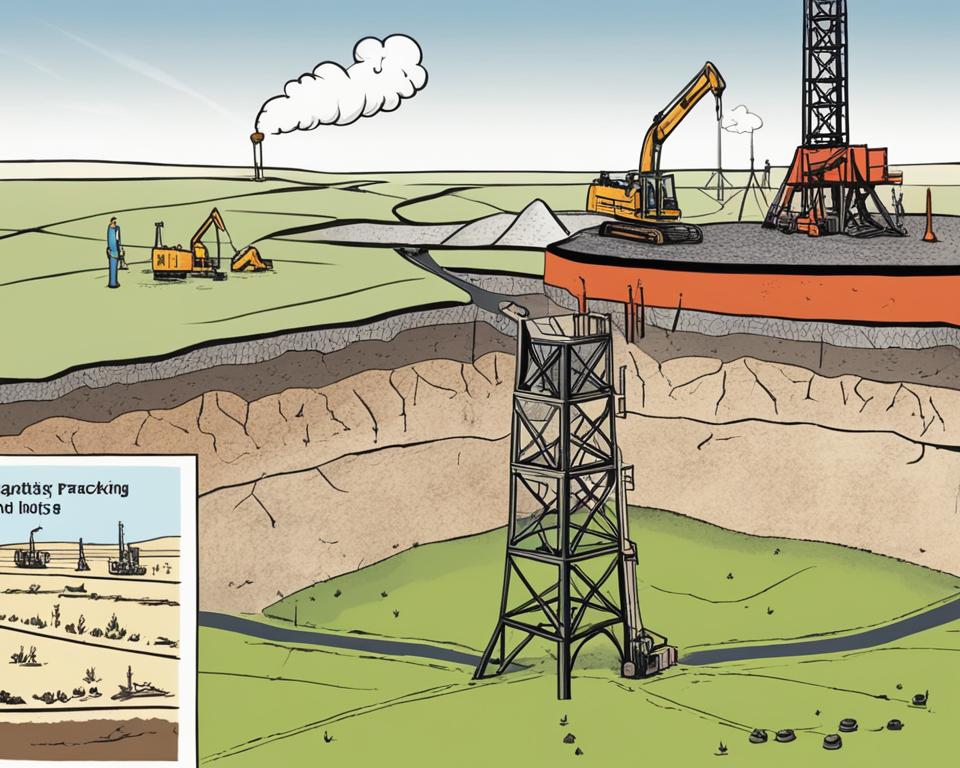

Fracking, also known as hydraulic fracturing, is a complex process that utilizes advanced techniques and technologies to extract natural gas or oil from rock formations deep underground. The combination of high-pressure fluid injection, horizontal drilling, and specific fracturing fluids has revolutionized the industry and significantly increased production rates. Let’s take a closer look at the fundamental fracking techniques and the technological advancements that have shaped the field.

Drilling and Well Preparation

The fracking process begins with drilling a well into the target rock formation. Initially drilled vertically, the well is then gradually turned horizontal to maximize contact with the reservoir rock. Steel casings are inserted into the well, ensuring stability and preventing contamination of surrounding formations. Cement is then injected between the casing and the wellbore to create a secure seal.

Fracturing Fluid Injection

Fracking relies on the injection of fluid at high pressures to create fractures in the rock, allowing the release of trapped hydrocarbons. The fracturing fluid, typically a mixture of water, sand, and chemical additives, is pumped into the well and forced into the rock formation. The pressure exerted by the fluid creates fractures, which are held open by proppants (like sand) to allow for the flow of oil or gas.

The technology used in fracking fluid has seen significant advancements over the years. One notable development is the use of slickwater, a type of low-viscosity fracturing fluid that enables better penetration into the rock and increases resource recovery. The composition of the fluid can vary depending on the specific geological characteristics of the target formation.

Horizontal Drilling and Multi-Stage Fracturing

Advances in drilling techniques have played a crucial role in the success of fracking operations. Through the use of horizontal drilling, wells can access a larger surface area of the reservoir, maximizing production. By extending the wellbore horizontally through the rock formation, operators can tap into more pockets of trapped hydrocarbons.

In conjunction with horizontal drilling, multi-stage fracturing has become a standard practice. This technique involves isolating specific sections of the wellbore using packers and perforating the casing at multiple intervals. Each stage is then hydraulically fractured, creating a network of fractures that extends further into the reservoir, enabling higher production rates.

Fracking Technology Advancements

The continuous advancement of fracking technology has significantly improved the efficiency and productivity of the process. Innovations in well design, including optimized well spacing and placement, have led to better resource recovery and reduced environmental impact.

Additionally, improved monitoring and data collection techniques have enhanced the understanding of fracking operations, enabling operators to make more informed decisions. Real-time data analysis, including pressure and temperature measurements, allows for better control and optimization of the fracturing process.

| Fracking Technique | Description |

|---|---|

| Directional Drilling | Drilling wells that change direction to access a larger surface area of the reservoir. |

| Multi-Stage Fracturing | Hydraulically fracturing wells at multiple intervals to maximize resource recovery. |

| Slickwater Fracking | Using low-viscosity fracturing fluid to improve penetration into the rock formation. |

| Real-Time Monitoring | Collecting and analyzing data during fracking operations to optimize performance. |

These advancements in fracking techniques have propelled the industry forward, enabling the extraction of previously inaccessible resources. However, it is important to ensure that these techniques are used responsibly and adhere to strict environmental regulations to mitigate any potential risks associated with fracking operations.

Environmental Impacts of Fracking

Fracking, as a widely used extraction technique, has raised concerns about its environmental impacts. The process of hydraulic fracturing consumes large amounts of water, estimated to be anywhere from 1.5 million to 9.7 million gallons per well. Such significant water consumption poses a strain on freshwater resources, especially in regions with limited water supply.

One of the major concerns surrounding fracking is the potential for groundwater contamination. Reports have emerged indicating groundwater contamination in areas with high levels of fracking activities. However, it is important to note that studies have not definitively proven a direct link between fracking and water contamination.

Furthermore, fracking operations can have adverse effects on air quality. The process releases volatile organic compounds (VOCs) and other pollutants into the atmosphere, contributing to air pollution. Additionally, noise pollution is another environmental impact associated with fracking, which can affect both human and animal populations. Lastly, the generation of large amounts of wastewater during fracking operations poses challenges in its safe disposal.

Regulations have been implemented to address these concerns and mitigate the environmental impacts of fracking. However, the effectiveness of these regulations is the subject of ongoing debate among stakeholders. Striking a balance between energy production and environmental protection remains a crucial challenge for policymakers.

Fracking Controversy

Fracking has become a highly controversial subject, attracting significant attention and sparking lively debates. The potential environmental and health impacts associated with the process have raised concerns among environmentalists, local communities, and the general public.

One of the primary concerns surrounding fracking is the potential contamination of water resources. The high-pressure injection of fluids used in the fracking process can lead to the release of harmful chemicals and pollutants into groundwater sources. There have been reports of instances where nearby water supplies have been compromised, leading to concerns about the safety of drinking water.

In addition to water contamination, the release of air pollutants during fracking operations is another area of concern. The extraction and processing of natural gas and oil through fracking can result in the emission of volatile organic compounds and greenhouse gases, contributing to air pollution and climate change.

Furthermore, the disposal of wastewater generated from fracking operations has also raised alarms. The volume of wastewater produced during the fracking process can be substantial, and the methods of disposal can pose risks to the environment if not properly managed.

Fracking controversy stems from concerns over water contamination, air pollution, and the disposal of wastewater.

The controversies surrounding fracking have prompted calls for more independent studies to assess the potential risks associated with the process. There is a need for comprehensive and unbiased research to better understand the environmental and health impacts of fracking, in order to inform decision-making and regulatory measures.

Additionally, there is growing demand for the implementation of more stringent regulations to ensure the safe and responsible use of fracking techniques. Stricter guidelines and oversight can help mitigate potential risks and address the concerns raised by communities and environmental advocates.

Related Reading:

- The History of Fracking: Exploring the Evolution of Hydraulic Fracturing

- Fracking Techniques: Understanding the Process Behind Hydraulic Fracturing

- Environmental Impacts of Fracking: Analyzing the Effects on Water, Air, and Climate

| Fracking Controversy | Key Points |

|---|---|

| Potential Water Contamination | Concerns about the release of harmful chemicals into groundwater sources. |

| Air Pollution | The extraction and processing of natural gas and oil can contribute to the emission of volatile organic compounds and greenhouse gases. |

| Wastewater Disposal | The management and disposal of large volumes of wastewater generated during fracking operations require careful consideration to minimize environmental risks. |

| Call for Independent Studies | The need for comprehensive research to assess the potential risks and impacts of fracking on the environment and public health. |

| Stricter Regulations | The importance of implementing robust regulatory measures to ensure the safe and responsible use of fracking techniques. |

Benefits of Fracking

Despite the controversy surrounding fracking, there are significant benefits associated with the process. Fracking has revolutionized the domestic oil and gas industry, leading to increased production and reducing the United States’ reliance on foreign sources of energy. The growth of the fracking industry has had numerous positive effects on the national economy, creating job opportunities and contributing to overall economic growth, particularly in areas with abundant shale formations. Additionally, fracking has had a direct impact on consumers, resulting in lower energy costs and increased energy security for the country.

The Impact on Domestic Energy Production

Fracking has played a crucial role in boosting domestic energy production in the United States. By tapping into previously inaccessible rock formations, we have unlocked vast reserves of natural gas and oil. This has not only reduced our dependence on foreign imports but has also transformed the United States into a global energy powerhouse. The growth of the fracking industry has resulted in a surge in production, leading to increased energy availability and stability for the nation.

Job Creation and Economic Growth

The expansion of the fracking industry has created numerous job opportunities, particularly in regions with large shale formations. From engineers and technicians to truck drivers and equipment operators, the demand for skilled workers has increased significantly. This growth in employment has had a positive impact on local economies, stimulating economic development, and supporting small businesses. The revenue generated from fracking activities has also resulted in increased tax revenues for local governments, which can be allocated to infrastructure projects and public services.

Lower Energy Costs and Increased Energy Security

Fracking has directly contributed to lower energy costs for consumers. The increased production of natural gas and oil has led to a more abundant supply, driving prices down and reducing the burden on households and businesses. This affordability has not only benefited individual consumers but has also had a positive impact on industries that rely heavily on energy, such as manufacturing and transportation. Furthermore, by reducing our dependence on foreign energy sources, fracking has enhanced the nation’s energy security, ensuring a more stable and resilient energy supply.

Overall, despite the ongoing debates and concerns surrounding fracking, it is essential to acknowledge the significant benefits associated with this technique. The industry’s growth has resulted in increased domestic energy production, job creation, economic growth, lower energy costs, and enhanced energy security for the United States.

Fracking Equipment and Fluids

Fracking requires specialized equipment to effectively extract oil or natural gas from rock formations. This equipment includes high-pressure pumps, blenders for fracking fluids, and storage tanks for various components. Fracking fluids, which play a crucial role in the process, are composed of water, sand, and chemical additives.

The combination of these components serves different purposes in the fracking process:

- Water: Water is the primary component of fracking fluids, making up the majority of the composition. It acts as a carrier for the other components and helps create the necessary pressure to fracture the rock formations.

- Sand: Sand, specifically high-quality quartz known as “frac sand,” is added to the fracking fluid to keep the fractures open after the pressure is released. This allows for the efficient flow of oil or gas from the rock formation to the well.

- Chemical Additives: Chemical additives are an essential part of fracking fluids and serve various purposes. They can dissolve minerals, prevent equipment corrosion, eliminate bacteria that could harm the well, and carry proppants into the fractures.

The specific composition of fracking fluids can vary based on the unique requirements of each fracking site. While most states have regulations in place that require the disclosure of the chemicals used in these fluids, there are exemptions to protect trade secrets.

The table below provides an overview of the components used in fracking fluids:

| Component | Function |

|---|---|

| Water | Serves as the primary carrier and helps create pressure for fracturing the rock formations. |

| Sand | Keeps fractures open after pressure is released, allowing for the efficient flow of oil or gas. |

| Chemical Additives | Dissolve minerals, prevent equipment corrosion, eliminate bacteria, and transport proppants into fractures. |

Proppants Used in Fracking

In hydraulic fracturing, proppants play a critical role in maintaining fractures in the rock formation open after the injection of fracking fluids. The use of proppants ensures the efficient flow of oil and gas from the formation to the well casing. The most commonly used proppant in the fracking industry is sand, specifically known as “frac sand.”

Types of Proppants

Sand, particularly high-purity quartz sand, is the preferred proppant due to its round shape, uniform size, and crush resistance. This type of sand, also referred to as frac sand, offers the ideal properties to effectively prop open fractures, allowing the release of hydrocarbons.

Proppant Production

The United States is the largest producer of frac sand, with a significant concentration of production in the Great Lakes Region. The demand for frac sand has soared as the fracking industry has expanded, leading to the establishment of numerous sand mining operations.

Benefits of Frac Sand

The unique characteristics of frac sand make it an indispensable component in fracking operations. Its high crush resistance ensures that fractures remain open, enabling the efficient extraction of oil and gas. Additionally, frac sand’s uniform size allows for optimal permeability, further enhancing the flow of hydrocarbons.

Comparison of Different Proppants

| Proppant Type | Properties | Applications |

|---|---|---|

| Sand (Frac Sand) | High crush resistance, round shape, uniform size | Mainly used in hydraulic fracturing of shale formations |

| Aluminum Oxide | High strength, thermal stability | Used in high-temperature fracturing operations |

| Ceramic | High strength, chemical resistance | Utilized in specialized fracturing applications |

“The use of proppants in hydraulic fracturing is crucial for maintaining fractures open and optimizing the flow of oil and gas from the rock formation to the well casing.”

Fracking Fluids and Chemicals

Fracking fluids play a crucial role in the hydraulic fracturing process, containing a mixture of water, chemical additives, and proppants. The composition of these fluids can vary depending on the specific needs of each fracking site. Chemical additives are used for various purposes, including dissolving minerals, eliminating bacteria, reducing friction, and preventing corrosion.

However, it is important to note that many chemicals used in fracking fluids are considered hazardous to human health. There have been concerns about the potential health impacts of exposure to these chemicals, especially for workers in the industry and nearby communities.

“The use of such chemicals in fracking fluids is a point of ongoing debate and research, as the potential risks are not yet fully understood,” says Dr. Emma Thompson, a renowned environmental scientist.

Fracking companies often argue that the chemicals used in their fluids are trade secrets and, therefore, exempt from public disclosure. This lack of transparency has fueled public concern and calls for stricter regulations regarding the use of chemicals in fracking fluids.

While some states require the disclosure of chemicals used in fracking fluids, there are often exceptions for “confidential business information.” This exception is intended to protect trade secrets, but it has also raised questions about the potential risks of these undisclosed chemicals.

To illustrate the complexity of fracking fluids and the potential chemical hazards involved, we have compiled a table outlining some commonly used chemical additives:

| Chemical Additive | Main Purpose | Potential Health Impact |

|---|---|---|

| Polyacrylamide | Friction Reducer | Possible skin and respiratory irritation |

| Biocides | Bacteria Elimination | May cause skin and eye irritation; potential environmental toxicity |

| Corrosion Inhibitors | Preventing equipment corrosion | Depending on the specific chemical used, potential toxicity and environmental impact |

| Surfactants | Reducing water surface tension | May cause skin and eye irritation; potential aquatic toxicity |

It is crucial for regulators and the industry to prioritize the safety of workers, communities, and the environment when evaluating the use of chemicals in fracking fluids. Stricter regulations and increased transparency regarding the composition of these fluids can help address concerns and ensure that the potential risks are mitigated.

Water Consumption in Fracking

Fracking, although a valuable technique for extracting natural gas or oil, comes with significant consequences for water resources. The process can consume a substantial amount of water, ranging from 1.5 to 9.7 million gallons per well. This water is predominantly sourced from both groundwater and surface water supplies, placing additional strain on already limited freshwater resources.

Efforts have been made to use nonpotable water for fracking, aiming to minimize the impact on freshwater supplies. However, in areas where freshwater resources are already scarce, the continued use of these sources for fracking exacerbates the challenge of water supply depletion.

Additionally, the wastewater generated from fracking operations poses its own set of challenges. The water produced during the fracking process is highly contaminated and typically unsuitable for direct reuse or return to its source. As a result, it requires extensive treatment before disposal or is injected deep underground, further removing it from the natural water cycle.

The Impact of Water Consumption in Fracking

The excessive demand for water puts considerable pressure on water supplies in regions where fracking activities are prevalent. This is particularly problematic in areas already experiencing water scarcity or competing demands for freshwater resources, such as agricultural needs or drinking water supplies for local communities.

The disposal of wastewater generated from fracking operations also presents challenges. The underground injection of wastewater can carry its own environmental risks, potentially affecting water quality and potentially contributing to seismic activity in some cases.

Summary of Water Consumption in Fracking

Fracking’s significant water consumption and the disposal of its wastewater have raised concerns about the long-term sustainability of this extraction technique. As water supply depletion becomes a growing issue, it becomes crucial to strike a balance between meeting energy needs and conserving water resources.

| Water Consumption in Fracking | Challenges |

|---|---|

| High water demand, ranging from 1.5 to 9.7 million gallons per well | Strain on freshwater supplies, particularly in areas already experiencing water scarcity |

| Wastewater generation and disposal | Requires extensive treatment for reuse or underground injection, limiting its return to the natural water cycle |

| Impact on water resources | Potential risks to water quality and the environment |

Risks of Water Contamination

Fracking operations pose significant risks to water resources, including the potential for contamination. Throughout the fracking process, spills and leaks of fracking fluids can occur, endangering water quality. These incidents can happen during transportation, mixing and pumping, as well as storage and disposal of used fluids. While reports indicate that some spilled fluids have reached surface water resources, the full extent of the impact remains uncertain due to incomplete information about the chemical composition of the spilled fluid.

Several studies have raised concerns about the potential for groundwater contamination as a result of fracking operations. The injection of fracking fluids deep underground can potentially lead to the migration of contaminants into underground water sources. However, the link between fracking and water contamination is still subject to ongoing debate and research.

It is essential to address the risks associated with water contamination to protect our precious water resources. Public awareness, comprehensive monitoring, and stringent regulations can help mitigate the potential adverse impacts of fracking on water quality.

“We need to prioritize the protection of our water resources and take proactive measures to prevent and address water contamination risks associated with fracking. The potential consequences of contamination are far-reaching, and we must ensure the responsible and safe management of fracking operations.”

Overview of Water Contamination Risks:

- Spills and leaks of fracking fluids

- Inadequate understanding of the chemical composition of spilled fluids

- Concerns about migration of contaminants into groundwater

- Ongoing scientific research and debate on the link between fracking and water contamination

Safety and Regulation in Fracking

Ensuring safety and protecting the environment are paramount in the fracking industry. Regulations have been put in place to safeguard both workers and the surrounding communities. However, the landscape of fracking regulations is not uniform across states, leading to varying levels of oversight and potential gaps in oversight.

One significant regulation that comes into play is the Safe Drinking Water Act. This federal law regulates the underground injection of fluids but specifically exempts fracking from such regulations. This exemption has stirred controversy and sparked calls for stricter regulations on fracking operations.

Adherence to safety procedures is crucial to prevent environmental contamination and safeguard public health. Fracking companies must have robust safety protocols in place and ensure that all workers are trained in and follow these procedures diligently.

Additionally, proper management of fracking fluids and wastewater is essential. The safe disposal and treatment of wastewater generated during the fracking process help prevent contamination of water resources. Strict adherence to regulations and best practices in handling and disposing of these fluids is vital to minimize any potential harm.

By maintaining rigorous safety standards, implementing effective regulations, and closely monitoring compliance, the industry can mitigate the risks associated with fracking and protect both people and the environment.

Conclusion

Fracking, also known as hydraulic fracturing, has a rich history dating back to the 1860s. Over the years, advancements in technology and techniques have fueled the growth of the fracking industry, leading to increased domestic oil and gas production. However, along with the benefits, there are concerns about the environmental and health impacts of fracking.

Efforts are underway to address these concerns through ongoing research and the implementation of regulations. It is essential to ensure the safe and responsible use of fracking techniques to mitigate any potential risks. Striking a balance between energy production and environmental protection is crucial moving forward.

In conclusion, fracking has undoubtedly shaped the energy landscape, but it is essential to proceed with caution. By promoting transparency, conducting robust studies, and enacting effective regulations, we can mitigate the potential negative impacts of fracking while harnessing its benefits for our energy needs.

FAQ

What is the history of fracking?

Fracking, also known as hydraulic fracturing, dates back to the 1860s when it was used to increase well productivity. Since then, it has evolved with advancements in technology and techniques, leading to the significant growth of the fracking industry. For a detailed timeline of fracking history, please refer to the relevant section.

What are the techniques used in fracking?

Fracking involves the injection of high-pressure fluids into rock formations to create fractures and release trapped natural gas or oil. The process begins with drilling a well which is then turned horizontal to reach the desired rock formation. Steel pipes called casings are inserted into the well, and fracking fluid is pumped in at high pressures to create or open fractures. For a more detailed explanation of fracking techniques, please refer to the relevant section.

What are the environmental impacts of fracking?

Fracking has raised concerns about water consumption, groundwater contamination, air pollution, noise pollution, and the generation of wastewater. Regulations have been put in place to address these concerns, but there is ongoing debate about their effectiveness. For more information on the environmental impacts of fracking, please refer to the relevant section.

Why is fracking controversial?

Fracking is controversial due to concerns about water contamination, air pollution, and the disposal of wastewater. Environmentalists and local communities have called for more independent studies on the risks and stricter regulations. For a deeper understanding of the fracking controversy, please refer to the relevant section.

What are the benefits of fracking?

Fracking has led to increased domestic oil and gas production, reduced dependence on foreign energy sources, job creation, economic growth, lower energy costs, and increased energy security. To learn more about the benefits of fracking, please refer to the relevant section.

What equipment and fluids are used in fracking?

Fracking requires specialized equipment such as high-pressure pumps, blenders for fracking fluids, and storage tanks for water, sand, chemicals, and wastewater. Fracking fluids typically consist of water, sand, and chemical additives, the composition of which varies based on site-specific needs. For a more detailed explanation of the equipment and fluids used in fracking, please refer to the relevant section.

What are proppants used in fracking?

Proppants, such as sand or aluminum oxide, are used in fracking to keep fractures in rock formations open after the pressure subsides. The most commonly used proppant is high-purity quartz sand known as “frac sand.” For more information on proppants used in fracking, please refer to the relevant section.

What are fracking fluids and chemicals?

Fracking fluids contain water, chemical additives, and proppants. The composition of the fluids can vary depending on site-specific needs. Chemical additives serve various purposes such as dissolving minerals, eliminating bacteria, reducing friction, and preventing corrosion. While many chemicals used in fracking fluids are considered hazardous to human health, disclosure requirements vary, and exemptions exist to protect trade secrets. For more information on fracking fluids and chemicals, please refer to the relevant section.

How much water does fracking consume?

Fracking consumes significant amounts of water, ranging from 1.5 million to 9.7 million gallons per well. The use of freshwater sources for fracking can strain water supplies in areas with limited water resources. For more details on water consumption in fracking, please refer to the relevant section.

What are the risks of water contamination from fracking?

Fracking operations pose risks to water resources, including the potential for contamination. Spills, leaks, and incomplete information about the chemical makeup of spilled fluids can affect surface water and groundwater. While studies have raised concerns about groundwater contamination, the link between fracking and water contamination is still debated. For a more comprehensive understanding of the risks of water contamination from fracking, please refer to the relevant section.

How is fracking regulated for safety?

Fracking operations are subject to regulations aimed at ensuring safety and protecting the environment. However, regulations vary across states, and there may be gaps in industry oversight. Adherence to safety procedures and proper management of fracking fluids and wastewater are crucial to prevent environmental contamination and protect public health. For more information on safety and regulation in fracking, please refer to the relevant section.

Is there a conclusion on fracking?

Fracking is a complex issue with both benefits and concerns. Ongoing research and regulations are necessary to address environmental and health impacts and ensure the safe and responsible use of fracking techniques.