A well pump is an essential device that allows you to access water from your well and bring it into your home. But have you ever wondered how it actually works? In this article, we will explore the mechanism behind a well pump, giving you a clear understanding of its operation and the water extraction process.

Key Takeaways:

- A well pump is an electromechanical device that pumps water from a well into a house.

- It consists of an electric motor that drives an impeller or centrifugal pump.

- The pump creates pressure and uses suction to draw water into the system.

- There are different types of well pumps, including shallow well jet pumps, deep well jet pumps, and submersible pumps.

- Choosing the right well pump depends on factors such as well depth and water usage.

Components of a Well Pump System

A well pump system consists of several key components that work together to extract water from a well and deliver it to your home. Understanding these components is essential for maintaining and troubleshooting your well pump system.

Pump

The pump itself is the heart of the well pump system. There are two main types of pumps used in well systems: submersible pumps and centrifugal pumps. Submersible pumps are installed deep inside the well and are designed to be submerged in water. Centrifugal pumps, on the other hand, are located outside the well and use suction to draw water up from the well.

Pressure Tank

The pressure tank is a crucial component of the well pump system as it helps maintain a steady flow of water to your home. It is responsible for storing the water pumped from the well and maintaining pressure in the system. When the pressure drops below a certain level, the pressure tank triggers the pump to start, ensuring a continuous supply of water.

Control Switch

The control switch is responsible for turning the pump on and off based on the water level in the pressure tank. When the water level drops below a certain point, the control switch activates the pump to start pumping water into the tank. Once the tank reaches the desired pressure, the control switch shuts off the pump to prevent over pressurization.

In addition to these components, well pump systems may also include check valves, fittings, and other accessories to ensure proper functioning and maintenance of the system.

| Component | Description |

|---|---|

| Pump | The main component responsible for extracting water from the well. |

| Pressure Tank | Stores the pumped water and helps maintain pressure in the system. |

| Control Switch | Turns the pump on and off based on water level in the tank. |

| Check Valves | Prevent backflow and ensure water only flows in one direction. |

| Fittings | Connect various components of the well pump system. |

Understanding the components of a well pump system is essential for troubleshooting and maintaining your well pump. By familiarizing yourself with how each component works, you can address any issues that may arise and ensure a reliable supply of water to your home.

Types of Well Pumps

When it comes to choosing a well pump, there are different options available depending on the depth of your well. The three main types of well pumps are shallow well jet pumps, deep well jet pumps, and submersible pumps.

Shallow Well Jet Pumps

Shallow well jet pumps are designed for wells that are less than 25 feet deep. They work by creating a vacuum that draws water up through a suction pipe. These pumps are often installed above ground, near the well, and are connected to a jet assembly that is lowered into the well. Shallow well jet pumps are suitable for smaller properties with shallower wells.

Deep Well Jet Pumps

If your well is deeper than 25 feet, a deep well jet pump may be the right choice. These pumps are capable of drawing water from depths of up to 110 feet. Deep well jet pumps utilize a two-pipe system, with one pipe for suction and another for the delivery of water. They work by creating a vacuum that pulls water up to the surface. Deep well jet pumps are typically installed above ground, near the well, and are suitable for larger properties with deeper wells.

Submersible Pumps

Submersible pumps are versatile and can be used in both shallow and deep wells. These pumps are installed directly in the well, submerged underwater. They are known for their durability and low maintenance requirements. Submersible pumps are powered by an electric motor located above ground and use impellers to push water up the pipe and into the storage tank. They are a popular choice for their efficiency and ability to handle larger volumes of water.

In summary, when choosing a well pump, it is important to consider the depth of your well. Shallow well jet pumps are suitable for wells less than 25 feet deep, while deep well jet pumps are designed for wells up to 110 feet deep. Submersible pumps are versatile and can be used in both shallow and deep wells. By selecting the right type of well pump, you can ensure a reliable water supply for your household needs.

How a Centrifugal Pump Works

A centrifugal pump is a commonly used type of well pump that operates by rotating an internal fan to create suction. This type of pump is typically installed next to the well and is suitable for shallow wells that are less than 25 feet deep. Understanding how a centrifugal pump works is important for maintaining its optimal performance and ensuring a continuous water supply.

Water Suction in a Centrifugal Pump

Centrifugal pumps work by utilizing centrifugal force to move water. The internal fan, also known as an impeller, rotates rapidly when the pump is activated. As the impeller spins, it creates a centrifugal force that pushes the water toward the outer edges of the pump. This force creates a suction effect, drawing water into the pump through an inlet pipe or hose.

Once inside the pump, the water is propelled by the spinning impeller and forced through a discharge pipe or hose, eventually reaching its destination such as a storage tank or household plumbing system. It’s important to note that centrifugal pumps are designed for pumping water only and should not be used for other liquids or materials.

Centrifugal pumps are highly efficient and require minimal maintenance. However, it is essential to regularly inspect the pump for any signs of damage or wear and tear. Routine maintenance tasks may include cleaning the impeller, checking the motor for proper functioning, and ensuring all connections are secure. By properly maintaining a centrifugal pump, its lifespan can be extended, and performance can be optimized.

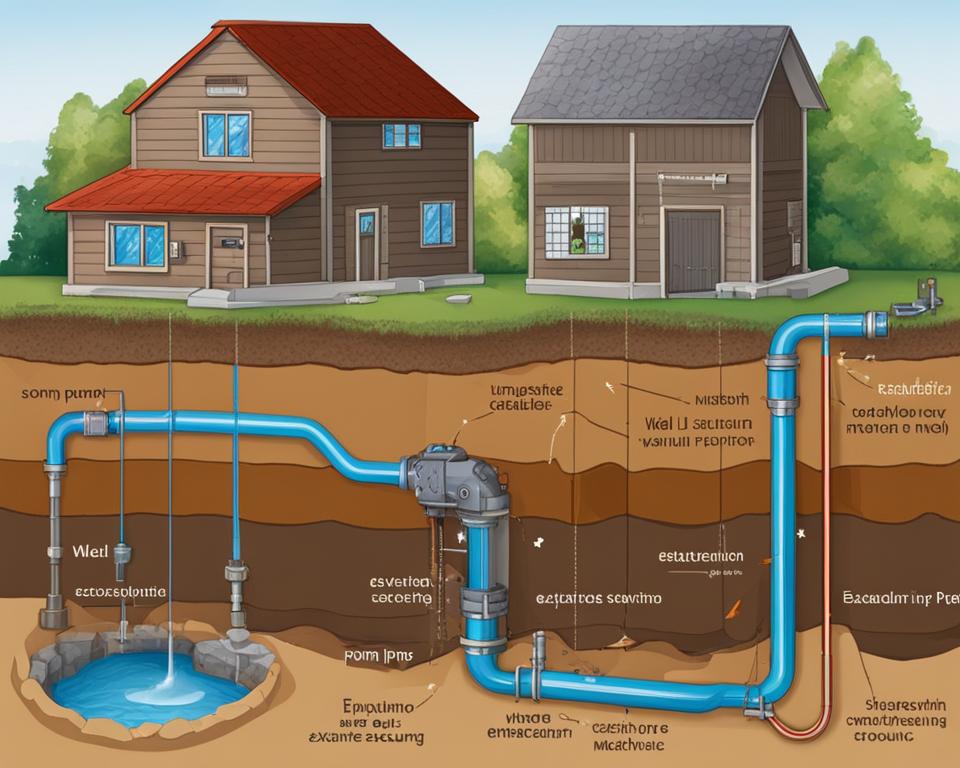

A Visual Representation of Water Suction in a Centrifugal Pump

Above is an image that visually represents the process of water suction in a centrifugal pump. As the impeller rotates, water is drawn into the pump through the inlet and propelled outward by the centrifugal force, resulting in a continuous flow of water. This visual representation helps to illustrate the mechanics of a centrifugal pump and its water suction process.

In summary, a centrifugal pump operates by rotating an internal fan to create suction, drawing water into the pump and propelling it through a discharge pipe or hose. This type of pump is ideal for shallow wells and requires minimal maintenance. By understanding how a centrifugal pump works and performing routine maintenance tasks, homeowners can ensure a reliable and efficient water supply from their well.

How a Submersible Pump Works

A submersible pump is a type of well pump that is designed for underwater installation. It is installed deep inside the well and operates by using an electric motor to power impellers that push water up the pipe. Submersible pumps are known for their durability and low maintenance requirements, making them a popular choice for both residential and commercial well systems.

Unlike other types of well pumps, submersible pumps are completely submerged in water, allowing them to operate silently and efficiently. The electric motor is sealed in a watertight casing, protecting it from water damage and ensuring reliable performance. This design also eliminates the need for priming and suction, as the water is directly pushed up the pipe by the impellers.

Submersible pumps are capable of pumping water from both shallow and deep wells, making them versatile in different well depths. They are suitable for wells with depths ranging from a few feet to several hundred feet. With their underwater installation and efficient operation, submersible pumps are an excellent choice for homeowners who want a reliable and long-lasting well pump system.

“Submersible pumps offer superior performance and durability compared to other well pump options. Their underwater installation eliminates priming and suction issues, while their sealed motor design ensures long-lasting operation.” – Well Pump Expert

Advantages of Submersible Pumps:

- Efficient and quiet operation

- Durable and long-lasting

- Low maintenance requirements

- Ability to pump water from various well depths

- No priming or suction needed

Disadvantages of Submersible Pumps:

- Higher initial cost compared to other pump types

- Requires professional installation

- Difficult to access for maintenance and repairs

When considering a submersible pump for your well, it is important to consult with a professional to ensure proper sizing and installation. They will be able to assess the depth of your well and recommend the appropriate pump size for your needs. With proper maintenance and care, a submersible pump can provide a reliable and efficient water supply for many years to come.

| Advantages | Disadvantages |

|---|---|

| Efficient and quiet operation | Higher initial cost compared to other pump types |

| Durable and long-lasting | Requires professional installation |

| Low maintenance requirements | Difficult to access for maintenance and repairs |

| Ability to pump water from various well depths | |

| No priming or suction needed |

How a Jet Pump Works

A jet pump is a versatile type of well pump that operates by using water to create pressure. It is capable of working in wells of all depths and provides high water flow rates. The operation of a jet pump involves the use of impellers that move water through a small orifice, increasing its speed. The pressure generated by the impellers pushes the water up into a tank located on the surface.

Jet Pump Mechanism

Jet pumps work on the principle of suction and pressure. When the pump is turned on, water is drawn from the well through a suction pipe into the pump. The impellers inside the pump increase the speed of the water, creating a vacuum that pulls more water from the well. This process, known as suction, allows the pump to draw water up from greater depths.

Once the water reaches a certain pressure, determined by the settings of the pump’s control switch, it is forced through a small orifice, which further increases its speed. The increased speed generates pressure, propelling the water up the discharge pipe and into the storage tank or directly into the household plumbing system.

| Advantages | Considerations |

|---|---|

| Can work in wells of all depths | Requires a larger well casing size |

| Provides high water flow rates | May require more maintenance compared to other pump types |

| Relatively affordable and easy to install | May be less energy efficient compared to other pump types |

A jet pump is a reliable choice for homeowners who need a well pump that can operate effectively in wells of any depth. Its ability to create high water flow rates ensures a consistent supply of water for household needs. However, it’s important to consider that jet pumps may require more maintenance and may be less energy-efficient compared to other pump types. Additionally, they require a larger well casing size, so it’s crucial to ensure that your well is capable of accommodating a jet pump.

When choosing a jet pump for your well, consult with a professional to determine the appropriate pump size and specifications based on your well depth and water usage requirements. Regular maintenance, including checking the pressure gauge and inspecting the pump for any signs of damage, will help ensure the longevity and optimal performance of your jet pump system.

Choosing the Right Well Pump

When it comes to choosing the right well pump for your property, several factors need to be considered. The size of your property, the amount of water your household uses, and the depth of your well all play a crucial role in determining the most suitable well pump for your needs.

If you have a shallow well that is less than 25 feet deep, a shallow well jet pump is recommended. These pumps are specifically designed for wells with shallow water tables and can effectively draw water from these depths.

For deep wells between 25 and 110 feet deep, a deep well jet pump is the ideal choice. These pumps are capable of drawing water from greater depths and provide efficient water extraction for deeper wells.

If your well is deeper than 110 feet, up to 400 feet, a four-inch submersible pump is the most suitable option. Submersible pumps are versatile and can be used in both shallow and deep wells, making them a reliable choice for varying well depths.

| Well Depth | Recommended Well Pump |

|---|---|

| Less than 25 feet | Shallow Well Jet Pump |

| 25 to 110 feet | Deep Well Jet Pump |

| 110 to 400 feet | Four-inch Submersible Pump |

The right well pump for your needs depends on the size of your property, the amount of water your household uses, and the depth of your well.

Accurately determining the depth of your well is essential in selecting the appropriate pump size. Installing a well pump that is not suitable for the depth of your well can result in inefficient water extraction and potential damage to the pump.

By understanding the specific needs of your property and well, you can make an informed decision when choosing the right well pump. Consult with a professional well pump installer to ensure that your selection aligns with your requirements and to receive expert guidance throughout the process.

Well Pump Maintenance Tips

Proper maintenance of your well pump is essential to ensure a continuous and reliable water supply. By following these maintenance tips, you can prolong the lifespan of your well pump and avoid costly repairs.

Regularly Check the Pressure Gauge

One of the key maintenance tasks for a well pump is to regularly check the pressure gauge on the pressure tank. The pressure gauge indicates the pressure level of the water in the tank. It is important to ensure that the pressure remains within the recommended range. If the pressure is too high or too low, it can indicate a problem with the well pump system.

Inspect the Pump and Pressure Tank

Regular inspections of the well pump and pressure tank are necessary to identify any signs of damage or wear. Look for leaks, cracks, or other visible damage on the pump and tank. Check the electrical connections for any loose wires or corrosion. Additionally, listen for any unusual noises coming from the pump while it’s running, as this could indicate a problem that needs attention.

Follow Recommended Maintenance Schedule

Each well pump manufacturer provides a recommended maintenance schedule for their specific pump model. It is important to follow this schedule to ensure that your well pump operates at its optimal level. Regular maintenance tasks may include lubricating the motor, replacing air release valves, and cleaning the pump components. By adhering to the manufacturer’s guidelines, you can prevent potential issues and extend the lifespan of your well pump.

Professional Inspection and Service

While regular maintenance can be performed by homeowners, it is also recommended to have a professional inspect and service the well pump at least once a year. A professional technician can diagnose any underlying issues, perform necessary repairs, and provide expert advice on maintaining your well pump system. This proactive approach can help prevent major breakdowns and ensure the continued functionality of your well pump.

By implementing these well pump maintenance tips, you can keep your well pump in optimal condition and enjoy a reliable water supply for your household needs.

Additional Water Storage for Wells

While a well pump system provides a reliable water supply, some well owners choose to install additional water storage tanks as a backup water supply. These tanks serve as a valuable solution during power outages, emergencies, or in areas prone to droughts or limited water resources.

It is important to note that additional water storage tanks should be seen as a supplement rather than a substitute for a well pump system. The well pump system remains the primary method of extracting water from the well and delivering it to your household. The additional storage tanks act as a backup, ensuring a continuous water supply during unforeseen circumstances.

By having additional water storage, you can have peace of mind knowing that you have a backup water source available when needed. These tanks can be filled when your well pump system is operational and store water for future use. However, it is important to regularly check and maintain these storage tanks to ensure the quality and cleanliness of the stored water.

Benefits of Additional Water Storage:

- Backup water supply during power outages

- Emergency water source during natural disasters

- Peace of mind during periods of drought or limited water resources

Having additional water storage tanks can provide you with a reliable backup water supply, safeguarding you against unforeseen circumstances. However, it is crucial to remember that proper maintenance and care of your well pump system should always be a priority to ensure a continuous and reliable water supply for your household needs.

Conclusion

In conclusion, understanding how a well pump works and choosing the right pump for your well is essential for ensuring a continuous supply of clean and reliable water. Whether you have a shallow or deep well, there are different types of well pumps available to meet your specific needs. It is important to accurately determine the depth of your well to choose the appropriate pump size.

Proper maintenance and care of the well pump system are crucial for its longevity and optimal performance. Regularly checking the pressure gauge, inspecting the pump and pressure tank for any damage, and following the manufacturer’s recommended maintenance schedule are important steps in ensuring a reliable water supply. Additionally, having a professional inspect and service the well pump at least once a year is highly recommended.

While additional water storage tanks can serve as a backup water supply during emergencies or in areas with limited water resources, they should not replace the need for a reliable well pump system. The maintenance and care of the well pump system should always remain a top priority to ensure a continuous and reliable water supply for your household needs.

FAQ

How does a well pump work?

A well pump is an electromechanical device that uses an electric motor to drive an impeller or centrifugal pump. It creates pressure in a storage tank and uses suction to draw water from the well, pushing it to the surface and into the tank.

What are the components of a well pump system?

A well pump system includes the pump itself, a pressure tank, and a control switch. The pump can be a submersible pump or a centrifugal pump, while the pressure tank stores the water and maintains system pressure. The control switch turns the pump on and off based on water level.

What are the types of well pumps available?

There are shallow well jet pumps, deep well jet pumps, and submersible pumps. Shallow well jet pumps are suitable for wells less than 25 feet deep, while deep well jet pumps can draw water from depths up to 110 feet. Submersible pumps can be used in both shallow and deep wells.

How does a centrifugal pump work?

A centrifugal pump operates by rotating an internal fan to create suction. It is installed next to the well and is suitable for shallow wells up to 25 feet deep.

How does a submersible pump work?

A submersible pump is installed deep inside the well and uses an electric motor to power impellers that push water up the pipe. It is suitable for both shallow and deep wells and is known for its durability and low maintenance requirements.

How does a jet pump work?

A jet pump uses water to create pressure. It has impellers that move water through a small orifice, increasing its speed. The pressure generated pushes the water up into a tank on the surface. Jet pumps can work in wells of all depths and provide high water flow rates.

How do I choose the right well pump?

The right well pump depends on the size of your property, water usage, and well depth. Shallow wells less than 25 feet deep require a shallow well jet pump, while deep wells between 25 and 110 feet deep need a deep well jet pump. Wells deeper than 110 feet can use a submersible pump.

What are some well pump maintenance tips?

Regularly check the pressure gauge, inspect the pump and pressure tank for damage, and follow the manufacturer’s schedule for replacing air release valves. Keep the pump area clean and have a professional inspect and service it annually.

Should I consider additional water storage for my well?

Additional water storage tanks can be useful as backup during power outages, emergencies, or in areas with limited water resources. However, they should not replace a reliable well pump system and should be seen as a supplement.

What is the conclusion about well pumps?

Understanding how a well pump works and choosing the right one is crucial for a continuous supply of clean water. Proper maintenance and care are essential for longevity and optimal performance. Consider additional storage options as backup, but prioritize the maintenance of the well pump system.