Welcome to our comprehensive guide on how to measure a screw accurately. Whether you are a DIY enthusiast or a professional, knowing the precise measurements of a screw is crucial for selecting the right size and type for your project. In this guide, we will walk you through the step-by-step process of measuring a screw’s length, diameter, and thread pitch. By following these techniques, you’ll be able to confidently measure screws and ensure the success and durability of your projects.

Key Takeaways:

- Measuring a screw accurately involves considering its length, diameter, and thread pitch.

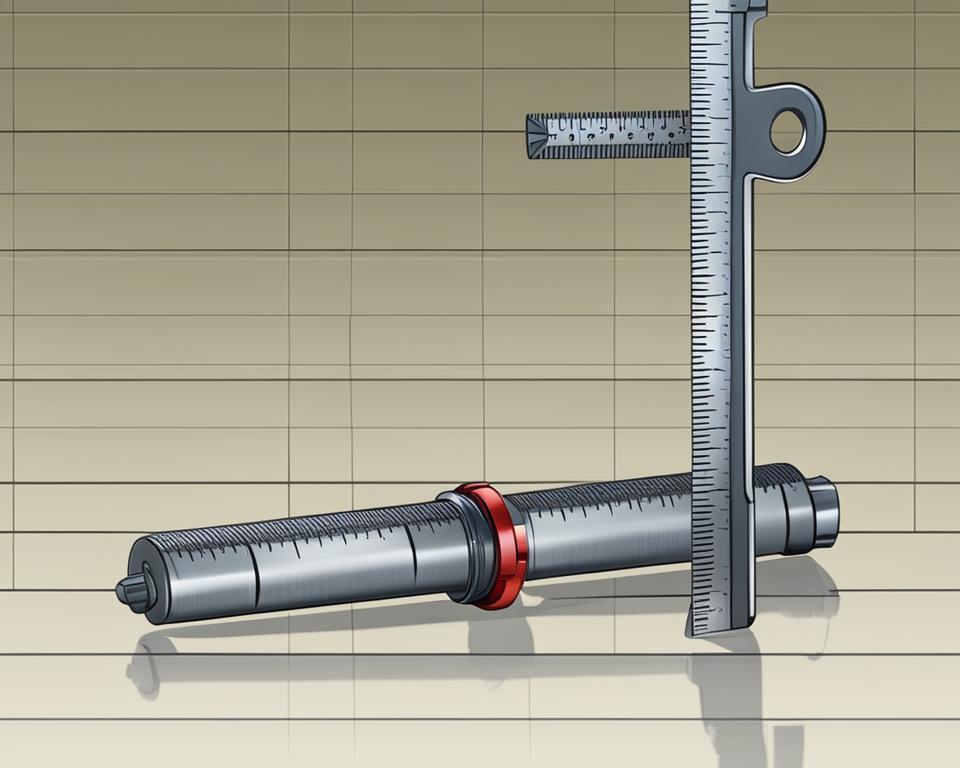

- Start by lining up the screw with a ruler and measuring from the tip to the head to determine the length.

- For the diameter, measure the width across the tip either in inches or millimeters and use conversion charts if needed.

- The thread pitch can be calculated by counting the number of threads per inch or checking the distance between two threads.

- Choose the appropriate unit system (imperial or metric) based on your region and the screws you are measuring.

Determining Screw Length

When it comes to measuring screws accurately, determining the length is crucial for selecting the right size for your project. The length of a screw is measured from the flat part of the head to the tip or blunt end. The specific measurement technique may vary depending on the type of screw head.

For screws with flat heads, you should measure from the bottom of the head to the tip. Countersunk screws, which have a flat head that sits flush with the surface, are measured from the top of the head to the tip. Hex and hex washer head screws are measured from the bottom of the head, while oval head screws are measured from the widest point of the head to the tip.

When dealing with self-drilling screws, it’s important to measure all the way to the end of the drill point tip. If you’re unsure about the size you need or have any questions, don’t hesitate to reach out to a fastener store or supplier for assistance.

Table: Screw Length Measurements by Head Type

| Screw Head Type | Measurement Technique |

|---|---|

| Flat Head | Bottom of head to tip |

| Countersunk Head | Top of head to tip |

| Hex/Hex Washer Head | Bottom of head to tip |

| Oval Head | Widest point of head to tip |

| Self-Drilling | All the way to the end of drill point tip |

Determining Screw Diameter

When it comes to measuring screws accurately, determining the diameter is a crucial step. The diameter of a screw refers to the width across the tip and is typically measured from the outer threads on one side to the outer threads on the other side. This measurement is known as the major diameter and is usually the proper size of the screw.

To measure the diameter, you can use a ruler or a caliper. Simply align the screw with the measuring tool and note the distance between the outer threads. You can measure in either inches or millimeters, depending on your preference or the screw’s specifications. If you are working with smaller screws, you may encounter a nominal measurement, represented by a number. This number indicates the size of the screw.

It’s worth noting that for more accurate measurements, you can also measure the minor diameter. The minor diameter is measured by finding the distance between the bottom cavity of the threads on one side to the other. This measurement gives you additional information about the size of the screw and can be helpful in certain applications.

Screw Size Chart

When determining the diameter of a screw, consulting a screw size chart can be a valuable resource. A screw size chart provides a reference guide that lists the various screw sizes and their corresponding measurements, including diameter, length, and thread pitch. This chart can help you quickly identify the right size of screw for your needs and ensure a precise fit.

| Screw Size | Diameter (inches) | Diameter (millimeters) |

|---|---|---|

| #2 | 0.086″ | 2.184 mm |

| #4 | 0.112″ | 2.844 mm |

| #6 | 0.138″ | 3.508 mm |

| #8 | 0.164″ | 4.165 mm |

Using a screw size chart can save you time and effort by providing an easy-to-use reference for screw measurements. Whether you’re a DIY enthusiast or a professional, having a reliable screw size chart on hand can help you select the right diameter for your projects with confidence.

Overall, accurately determining the diameter of a screw is essential for proper fitting and compatibility. By following the tips mentioned above and consulting a screw size chart, you can confidently measure the diameter of screws and ensure successful outcomes for your projects.

Understanding Thread Pitch

When it comes to measuring screw threads, understanding the thread pitch is essential. The thread pitch refers to the number and spacing of the threads on a screw, and it plays an important role in determining how tightly the screw will fit into a threaded hole. Whether you’re working with imperial or metric measurement systems, knowing how to measure thread pitch accurately is crucial for selecting the right screws for your project.

In the imperial system, thread pitch is typically measured by calculating the number of threads per inch. To determine the pitch, line up the screw next to a ruler and count the number of threads within the space of one inch. The most common pitch numbers range from 35 to 40 threads per inch. On the other hand, in the metric system, you can measure the thread pitch by checking the distance between two consecutive threads. For example, a screw with a 2 mm diameter will typically have a pitch of 0.4 mm between each thread.

Accurate measurement of thread pitch is important because it ensures that the screw will fit properly into the threaded hole. If the thread pitch is too coarse, the screw may not fit tightly, leading to a loose connection. Conversely, if the thread pitch is too fine, it may be difficult to insert the screw or it could easily strip the threads of the hole. By understanding the thread pitch and measuring it correctly, you can select screws that will provide a secure and robust connection for your project.

Table: Screw Thread Pitch Comparison

| Screw Diameter (in mm) | Thread Pitch (in mm) |

|---|---|

| 2 | 0.4 |

| 3 | 0.5 |

| 4 | 0.7 |

| 5 | 0.8 |

| 6 | 1.0 |

The table above shows a comparison of screw thread pitches for different screw diameters in the metric system. It provides a reference for understanding the relationship between screw diameter and thread pitch. By referring to a thread pitch chart or table, you can easily determine the appropriate thread pitch for a given screw diameter, ensuring a proper fit for your fastening application.

In conclusion, understanding thread pitch is essential for measuring screw threads accurately and selecting the right screws for your project. Whether you’re working with the imperial or metric system, knowing how to measure thread pitch allows you to determine the proper fit and ensure a secure connection. By following the guidelines provided and referring to thread pitch charts or tables, you can confidently measure screw threads and choose the right screws for your specific application.

Choosing the Right Measurement Units

When it comes to measuring screws, one important decision you need to make is whether to use metric or imperial units. The choice of measurement units depends on the system used in your region. In the United States, imperial units such as inches are commonly used, while in many other countries, the metric system with millimeters as the unit of measurement prevails.

Using the appropriate measurement units is crucial for accurate screw measurement. It ensures that you select the right screws that fit perfectly and securely in your projects. Mixing metric and imperial units can lead to compatibility issues and improper fits, compromising the integrity of your work.

When determining which measurement system to use, consider the following factors:

- Your location: If you are based in the United States, it is more convenient to use imperial units as they are the standard measurement system in the country.

- Industry norms: Consider the industry you are working in. Some industries or specific applications may have standardized measurement systems. For example, the automotive industry often uses metric units.

- Availability of screws: Check the availability of screws in your desired measurements. In some cases, certain sizes may be more readily available in either metric or imperial units.

By choosing the right measurement units, you can ensure accurate and consistent screw measurement, leading to successful projects and reliable results.

Tips for Measuring Screws Accurately

When it comes to measuring screws accurately, there are a few tips that can help you achieve precise results. By following these guidelines, you can ensure that your measurements are reliable and that you select the right screws for your project.

Use a Fine Resolution Ruler

Invest in a ruler or measuring tape with clear markings and a fine resolution. This will allow you to get precise measurements, especially when dealing with small screws or intricate details. Make sure the ruler is in good condition and that the markings are legible.

Align the Screw Properly

When measuring a screw, it’s important to align it properly with the ruler or measuring tape. Ensure that the screw is straight and parallel to the measuring tool to get an accurate reading. This is particularly important when measuring the length of the screw or the diameter across the tip.

Double-Check Your Measurements

To ensure accuracy, it’s always a good idea to take multiple measurements. This is especially important if the screw has an irregular shape or if the measurements seem inconsistent. By double-checking your measurements, you can catch any errors or discrepancies and make the necessary adjustments.

Consult a Professional or Guide

If you’re unsure about any aspect of measuring screws or if you need assistance, don’t hesitate to consult a professional or refer to a screw measurement guide. These resources can provide valuable insights and ensure that you’re following the correct methods for accurate measurements.

By following these tips, you can measure screws accurately and confidently. Remember to use a fine resolution ruler, align the screw properly, double-check your measurements, and seek guidance when needed. With precise measurements, you can ensure the success and durability of your projects that require screws.

Using Screw Measurement Charts

One of the most helpful tools for accurately determining the size of a screw is a screw measurement chart. These charts provide a valuable reference for finding the appropriate measurements for screw length, diameter, and thread pitch. They can be particularly useful when measuring screws for replacement or when you need to match the size and specifications of the original screws.

By referring to a screw measurement chart, you can quickly and easily identify the exact screw size you need for your project. These charts typically include clear diagrams and measurements for different screw types and sizes, making it easier to understand and compare the dimensions. Additionally, you can use screw measurement charts to convert measurements between units, such as inches and millimeters, ensuring compatibility with different measurement systems.

“Screw measurement charts provide a valuable reference for finding the appropriate measurements for screw length, diameter, and thread pitch.”

Whether you’re a DIY enthusiast or a professional in the construction or manufacturing industry, having access to screw measurement charts can save time and reduce the chances of selecting the wrong size screw. Many hardware stores and online resources offer these charts for free, making them easily accessible to anyone in need of accurate screw measurements.

Next, let’s take a look at an example screw measurement chart that provides comprehensive information on screw sizes and dimensions:

| Screw Size | Length (inch) | Diameter (inch) | Thread Pitch (threads per inch) |

|---|---|---|---|

| #4 | 3/8 | 0.112 | 40 |

| #6 | 1/2 | 0.138 | 32 |

| #8 | 5/8 | 0.164 | 32 |

| #10 | 3/4 | 0.19 | 24 |

This table provides a quick reference for screws of different sizes and their corresponding length, diameter, and thread pitch. Using a chart like this, you can easily find the right measurements for your screws and ensure a precise fit for your projects.

So, the next time you need to accurately measure a screw, don’t forget to consult a screw measurement chart for reliable and precise information.

Finding Replacement Screws

When it comes to finding replacement screws, accurate measurements are crucial. Whether you’re repairing furniture, appliances, or machinery, using the right size and type of screws is essential for a secure and long-lasting solution. By measuring screws for replacement, you can ensure they match the size and specifications of the original screws.

To find the right replacement screws, start by measuring the length, diameter, and thread pitch of the screws you need to replace. Use a ruler or measuring tape to measure the length from the flat part of the head to the tip. For the diameter, measure the width across the tip of the screw. Finally, determine the thread pitch by counting the number of threads per inch or checking the distance between two threads.

Once you have accurate measurements, you can visit a hardware store or explore online suppliers to find the appropriate replacement screws. Using the measurements, you can search for screws that match the length, diameter, and thread pitch of the original screws. If you’re unsure about the measurements or need assistance, don’t hesitate to consult with a professional or refer to a screw measurement guide.

Tips for Finding the Right Replacement Screws

- Take accurate measurements of the length, diameter, and thread pitch of the original screws that need to be replaced.

- Consult a screw measurement guide or professional if you’re unsure about the measurements.

- Visit hardware stores or explore online suppliers to search for replacement screws that match the measurements of the original screws.

- Consider the material and type of the replacement screws to ensure they are suitable for your specific application.

- Double-check the measurements and compare them to the specifications provided by the manufacturers or suppliers.

By measuring screws for replacement and finding the right screws, you can complete your repair or project with confidence, knowing that you have chosen the correct size and type of screws. Accurate measurements are key to a successful replacement, ensuring a secure and reliable solution.

| Length | Diameter | Thread Pitch | Material |

|---|---|---|---|

| 1 inch | 0.25 inch | 20 threads per inch | Stainless Steel |

| 2 inches | 0.375 inch | 16 threads per inch | Brass |

| 1.5 inches | 0.3125 inch | 18 threads per inch | Zinc Plated |

Table 1: Example of Replacement Screw Specifications

Common Screw Sizing Techniques

Accurately measuring screws is essential for various projects, and there are several common techniques that can help you achieve precise results. By utilizing these popular methods, you can ensure that you select the correct size and type of screw for your specific application.

Ruler or Measuring Tape: Using a ruler or measuring tape with clear markings and a fine resolution is a straightforward method for measuring screws. Align the screw with the ruler, ensuring it lies flat against the measurement surface. Take multiple measurements to verify accuracy.

Screw Gauge Chart: A screw gauge chart is a handy reference tool that provides information on screw sizes, including length, diameter, and thread pitch. It can assist in determining the appropriate size for your screws and converting measurements between units, such as inches and millimeters.

Reference Guides: Reference guides, whether in print or online, can offer valuable insights into screw sizing techniques. These guides typically provide detailed instructions on how to measure screws accurately and may include visual aids or step-by-step instructions to ensure clarity.

Table: Comparing Common Screw Sizing Techniques

| Technique | Advantages | Disadvantages |

|---|---|---|

| Ruler or Measuring Tape | – Simple and widely accessible – Can provide direct measurements |

– May require additional tools for precise readings – Relies on manual alignment |

| Screw Gauge Chart | – Offers comprehensive screw size references – Helps with unit conversions |

– May not account for all variations in screw types – Does not provide hands-on measurements |

| Reference Guides | – Provides detailed instructions and visuals – Offers a comprehensive understanding of screw sizing |

– Requires additional resources – Relies on interpretation and reading comprehension |

These common screw sizing techniques serve as valuable tools to ensure accurate measurements. Depending on the complexity of your project and your access to resources, you may choose to utilize one or a combination of these methods. Remember to take your time, double-check your measurements, and consult additional resources if needed. With the right measurements, you can confidently select the appropriate screws for your projects, ensuring secure and reliable results.

Importance of Accurate Screw Measurements

Accurate screw measurements play a crucial role in the success and reliability of any project involving screws. By ensuring precise sizing, you can experience several benefits that contribute to the overall quality and performance of the final outcome. Here are some key reasons why accurate screw measurements are important:

1. Proper Fit and Functionality

Accurate screw measurements ensure a proper fit between components, preventing issues like stripped threads or loose connections. When screws are sized correctly, they provide the necessary stability and strength to hold everything securely in place. This is particularly important in applications where safety and reliability are critical factors.

2. Increased Efficiency

Precise screw sizing eliminates the need for trial and error, saving you time and effort during installation. When you know the exact measurements of the screws you need, you can easily find and select the appropriate replacements or new screws. This reduces the risk of delays and allows you to complete your projects efficiently.

3. Cost Savings

Accurate measurements help you avoid unnecessary expenses associated with purchasing the wrong screws. When you measure screws accurately, you can be sure that you are investing in the right size and type of screws for your specific application. This eliminates the need for returns or replacements, saving you money and resources.

Overall, accurate screw measurements are essential for achieving optimal performance, durability, and cost-effectiveness in any project. By taking the time to measure screws accurately, you can ensure a successful outcome and avoid potential issues that may arise from using improperly sized screws.

Tips for Successfully Measuring Screws

Accurately measuring screws is essential to ensure a secure fit and prevent issues like stripped threads. Here are some best practices to follow when measuring screws:

- Use a well-lit workspace: Adequate lighting will help you see the screw clearly and make accurate measurements. Avoid shadows or glare that may affect your readings.

- Take multiple measurements: To ensure consistency and accuracy, measure the screw multiple times using the same technique. This will help you confirm your measurements and reduce the chances of errors.

- Keep a record of measurements: It’s a good practice to write down or take pictures of the measurements for future reference. This will save you time if you need to find replacements or refer to the measurements later on.

- Consult a guide or professional: If you’re unsure about any aspect of the measuring process or need assistance, don’t hesitate to consult a reliable screw measurement guide or seek advice from a professional. They can provide valuable insights and ensure you’re measuring screws accurately.

By following these tips, you’ll be able to measure screws confidently and accurately for your projects. Remember that precision is key when it comes to selecting the right size and type of screws, ensuring the success and durability of your assemblies.

Common Mistakes to Avoid

While measuring screws, it’s important to avoid certain common mistakes to ensure accurate results:

- Using worn or inaccurate tools: Make sure your ruler or measuring tape is in good condition and clearly marked. Any wear or damage to the tools can affect your measurements.

- Not considering the thread length: When measuring the length of the screw, ensure you account for the threaded portion. Excluding the threads can result in an incorrect measurement.

- Confusing diameter and length: Pay attention to whether you’re measuring the diameter or length of the screw. Mixing up these measurements can lead to selecting the wrong size.

- Misinterpreting measurements: Take your time and double-check your readings to avoid misinterpreting the measurements. A small error can make a significant difference in finding the right screw size.

By avoiding these mistakes and adopting the best practices mentioned earlier, you’ll be well-equipped to measure screws accurately and ensure successful projects.

Conclusion

Measuring screws accurately is crucial for finding the right size and type of screws for your projects. By following the techniques and tips provided in this guide, you can confidently measure screws for various applications. Remember to consider the length, diameter, and thread pitch of the screws, and use the appropriate units of measurement based on your region.

When measuring screws, it is important to follow best practices to ensure accuracy and efficiency. Use a well-lit and clutter-free workspace to avoid errors or misreadings. Take measurements multiple times to ensure consistency and accuracy. Keep a record or take pictures of the measurements for future reference. Consult a screw measurement guide or seek professional advice if you are unsure about any aspect of the process.

Accurate measurements are essential for successful projects. Using the wrong size of screws can lead to stripped threads, poor holding power, or an insecure fit. By measuring screws accurately, you can ensure that they will securely hold components together, reducing the risk of damage or failure. Maintain the integrity and functionality of your projects by taking the time to measure screws correctly.

FAQ

How do I measure the length of a screw?

To measure the length of a screw, line it up with a ruler and measure from the tip to the head. For rounded heads, measure to the flat part where it will lie flush with the surface.

How do I determine the diameter of a screw?

Measure the width across the tip of the screw either in inches or millimeters. This is called the major diameter. For smaller sizes, a nominal measurement may be used.

What is thread pitch?

Thread pitch refers to the number and spacing of the threads on a screw. In the imperial system, it is measured by calculating the number of threads per inch. In the metric system, it is the distance between two threads.

Should I use imperial or metric units when measuring screws?

The choice of units depends on the system of measurement used in your region. In the United States, imperial units like inches are commonly used, while other countries use the metric system with millimeters as the unit of measurement.

What are some tips for measuring screws accurately?

Use a ruler or measuring tape with clear markings, ensure proper alignment, take multiple measurements, and consult a professional or screw measurement guide if needed.

How can screw measurement charts help?

Screw measurement charts provide a reference for screw sizes and their corresponding measurements. They can also help with converting measurements between units.

How do I find the right replacement screws?

Measure the length, diameter, and thread pitch of the original screws to find appropriate replacements. Consult a hardware store or online supplier for assistance.

What are some common screw sizing techniques?

Popular methods include using rulers or measuring tapes, screw gauge charts, and reference guides.

Why are accurate screw measurements important?

Accurate measurements ensure proper fit, holding power, and overall project integrity.

What are some tips for measuring screws successfully?

Maintain a well-lit and clutter-free workspace, take measurements multiple times, and consult guides or professionals when unsure.