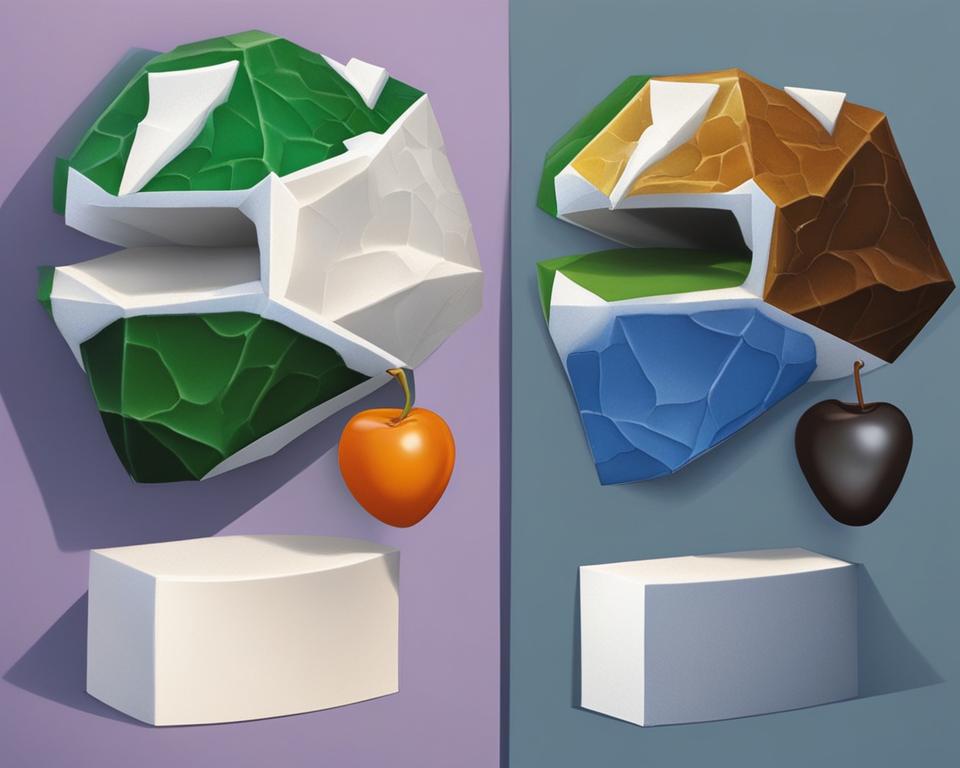

Styrofoam and polystyrene are often used interchangeably, but they are actually different. Styrofoam, a Dow trade name, is a blue extruded polystyrene (XPS) foam used for insulation, construction, and crafts. On the other hand, polystyrene refers to expanded polystyrene (EPS) available in various densities for insulation and a wide range of applications. EPS is environmentally friendly, recyclable, and cost-effective compared to XPS.

Key Takeaways:

- Styrofoam and polystyrene are different materials, with Styrofoam being an extruded polystyrene (XPS) foam and polystyrene being expanded polystyrene (EPS).

- EPS is more versatile and has a wide range of applications compared to Styrofoam.

- EPS is environmentally friendly, recyclable, and does not contain harmful chemicals.

- Styrofoam is primarily used for insulation, construction, and crafts.

- Choosing EPS over Styrofoam can contribute to a more sustainable future.

Differences Between Styrofoam and EPS

Styrofoam and EPS, despite being forms of polystyrene, have distinct differences. One noticeable difference is their color. Styrofoam is typically blue in color, while EPS is white.

Another significant distinction lies in their manufacturing processes. Styrofoam is made from extruded polystyrene (XPS) and is commonly used for thermal insulation, construction, and crafts. On the other hand, EPS is produced through the expansion of polystyrene beads and is available in various densities. EPS is used for insulation, construction, and a wide range of applications.

What makes EPS even more versatile is its ability to be shaped and molded into different forms. EPS can be molded into specific shapes or cut into blocks and then further shaped as required. This makes EPS ideal for a variety of applications, ranging from packaging to helmets, theater props, signage, and even GEOFOAM retaining walls.

| Styrofoam | EPS |

|---|---|

| Blue in color | White in color |

| Extruded polystyrene (XPS) | Expanded polystyrene (EPS) |

| Mainly used for thermal insulation, construction, and crafts | Used for insulation, construction, and a wide range of applications |

| Versatile and available in various shapes |

In summary, the differences between Styrofoam and EPS lie in their color, manufacturing process, and versatility. While Styrofoam is blue and made from extruded polystyrene, EPS is white, produced through expansion, and can be shaped into various forms. These distinctions make EPS a more versatile choice for different applications.

Environmental Impact of Styrofoam and EPS

The environmental impact of styrofoam and EPS is a crucial consideration in today’s world. Styrofoam, being XPS foam, has color dyes that can leach into the environment, posing a significant risk to ecosystems. This leaching process can contaminate soil, water, and even air, affecting both wildlife and human health. The disposal of styrofoam can also contribute to landfill pollution, as it is not biodegradable and takes hundreds of years to break down.

In contrast, EPS is considered more environmentally friendly. It is made from organic elements and does not contain harmful chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs). EPS can also be recycled, contrary to popular belief. Despite the misconception that EPS is not recyclable, it can be accepted at specific locations for recycling, reducing its environmental impact.

“EPS is environmentally friendly and recyclable, despite the misconception that it is non-recyclable.”

By choosing EPS instead of styrofoam, individuals and businesses can contribute to a more sustainable future. EPS is a versatile material that can be used in a wide range of applications, from packaging to construction, and its recyclability ensures that it can be repurposed and reused, reducing waste. By actively promoting the use and recycling of EPS, we can minimize the environmental impact of polystyrene and work towards a cleaner and greener planet.

| Environmental Impact | Styrofoam | EPS |

|---|---|---|

| Leaching of color dyes | Yes | No |

| Biodegradability | No | Slow |

| Recyclability | Challenging | Yes |

Uses and Applications of Styrofoam and EPS

Styrofoam, as XPS, is primarily used for thermal insulation in construction. Its excellent insulating properties make it a popular choice for walls, roofs, and floors in residential, commercial, and industrial buildings. Additionally, Styrofoam is widely used in the packaging industry to protect fragile items during shipping and transportation.

On the other hand, EPS has a wide range of uses and applications. Its versatility allows it to be used in various industries. EPS is commonly used for packaging materials due to its lightweight and protective nature. It is also extensively used in the construction industry for insulation, especially in roofs and walls. EPS can be easily shaped and molded, making it suitable for creating intricate designs for theater props and signage.

One specific application of EPS is in the production of helmets. Its shock-absorbing properties help protect the head from impact during sports activities and other high-risk situations. In civil engineering, EPS is used as GEOFOAM, a lightweight fill material used for embankments, retaining walls, and slope stabilization. The versatility of EPS allows it to be adapted for numerous purposes, making it a valuable material across various industries.

| Styrofoam Uses | EPS Uses |

|---|---|

| Thermal insulation in construction | Packaging materials |

| Protective packaging for fragile items | Construction insulation |

| Theater props and signage | |

| Helmets | |

| GEOFOAM for civil engineering projects |

As shown in the table above, Styrofoam’s main uses are focused on thermal insulation and packaging, while EPS has a wider range of applications in packaging, construction, theater, sports, and civil engineering.

Safety Concerns and Recyclability of Polystyrene

The safety concerns associated with Styrofoam (XPS) primarily stem from the color dyes used in the material. These dyes can leach into the environment, potentially causing harm. In contrast, EPS (expanded polystyrene) is composed of organic elements and does not contain harmful chemicals like chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs). This makes EPS a safer option in terms of environmental impact.

When it comes to recycling, EPS has an advantage over Styrofoam. EPS is recyclable and can be accepted at specific recycling locations. On the other hand, the recycling of Styrofoam, especially in the form of XPS, poses challenges. Styrofoam is not widely accepted for recycling, which has led to an accumulation of polystyrene waste in landfills. Efforts are underway to increase awareness about the recyclability of EPS and find sustainable solutions for polystyrene waste.

“EPS is composed of organic elements and does not contain harmful chemicals, making it a safer option. However, the recycling of Styrofoam, especially XPS, poses challenges.”

In order to address the safety concerns associated with Styrofoam and to promote a more sustainable approach to polystyrene waste, it is important for individuals and businesses to be aware of the differences between Styrofoam and EPS. By making informed choices about the use and disposal of these materials, we can contribute to a safer and more environmentally-friendly future.

Challenges in Recycling Polystyrene

Recycling polystyrene, especially Styrofoam, presents several challenges. One of the main challenges is the lightweight nature of the material, which makes it difficult to collect and transport for recycling. Additionally, the presence of contaminants such as dirt, food particles, and other materials can hinder the recycling process.

Another challenge is the lack of infrastructure and recycling facilities that are equipped to handle polystyrene recycling. While EPS is recyclable and accepted at certain locations, the same cannot be said for Styrofoam, which is primarily used in the form of XPS for insulation purposes.

Despite these challenges, efforts are being made to develop innovative recycling methods for polystyrene, including technologies that can break down the material and transform it into reusable products. By investing in research and development, as well as supporting policies that promote recycling and sustainable practices, we can work towards a more effective and efficient polystyrene recycling system.

Table: Polystyrene Recycling Challenges

| Challenge | Description |

|---|---|

| Lightweight nature | Polystyrene, especially Styrofoam, is lightweight, making it difficult to collect and transport for recycling. |

| Contamination | Polystyrene can often be contaminated with dirt, food particles, and other materials, which can hinder the recycling process. |

| Lack of infrastructure | There is a limited number of recycling facilities equipped to handle polystyrene recycling, leading to a lack of accessible options for recycling. |

| Specific recycling requirements | Polystyrene recycling may require specialized processes and equipment, which may not be readily available in all areas. |

Table: Challenges in recycling polystyrene

Conclusion

After exploring the differences between Styrofoam and EPS, it is clear that they serve different purposes. Styrofoam, also known as XPS, is mainly used for insulation, construction, and crafts. On the other hand, EPS, or expanded polystyrene, is a versatile material with a wide range of applications.

One of the key distinctions between these two materials is their environmental impact. Styrofoam, being XPS, has color dyes that can leach into the environment, raising concerns about its sustainability. In contrast, EPS is made of organic elements and does not contain harmful chemicals. It is considered more environmentally friendly and recyclable.

When it comes to uses, Styrofoam is primarily used for thermal insulation in construction, while EPS has endless possibilities. EPS can be shaped, molded, and cut into various forms and sizes, making it suitable for packaging, construction, helmets, theater props, signage, and even civil engineering projects like GEOFOAM retaining walls.

While there are challenges in recycling polystyrene, efforts are underway to increase awareness and find sustainable solutions. Making informed choices about the use and disposal of styrofoam and EPS can contribute to a more sustainable future. By opting for EPS and considering its recyclability, we can minimize the environmental impact and create a positive change for our planet.

FAQ

What is the difference between Styrofoam and EPS?

Styrofoam is a blue extruded polystyrene (XPS) foam primarily used for insulation, construction, and crafts. EPS refers to expanded polystyrene, which is available in various densities and used for insulation and a wide range of applications. EPS is white and more versatile compared to Styrofoam.

Is Styrofoam environmentally friendly?

Styrofoam is not considered environmentally friendly due to its potential to leach color dyes into the environment. On the other hand, EPS is made of organic elements, does not contain harmful chemicals, and is considered more sustainable.

Can EPS be recycled?

Yes, EPS can be recycled. While there may be challenges in recycling polystyrene, efforts are being made to increase awareness and find sustainable solutions for the recycling of EPS.

What are the uses of Styrofoam?

Styrofoam is primarily used for thermal insulation in construction and can also be used for crafts.

What are the uses of EPS?

EPS has a wide range of uses and applications. It can be used for packaging, construction, insulation, helmets, theater props, signage, and even as GEOFOAM in civil engineering projects.

Are there any safety concerns with Styrofoam?

Styrofoam may have safety concerns due to the color dyes that can leach into the environment. On the other hand, EPS is composed of organic elements and does not contain harmful chemicals.

Can Styrofoam be recycled?

Styrofoam recycling can be challenging, and it is not widely accepted for recycling. However, efforts are being made to increase awareness about the recyclability of EPS and find sustainable solutions for polystyrene waste.

![Ray Dalio Quotes [Principles, Life, Investment]](https://tagvault.org/wp-content/uploads/2023/04/Screen-Shot-2023-04-19-at-7.57.49-PM.png)