High oil pressure is a common concern among vehicle owners, but what exactly causes it?

In this article, we will delve into the various factors that can lead to high oil pressure, the symptoms to watch out for, and the potential problems that can arise if it is left unaddressed.

Oil pressure is a crucial aspect of engine performance and lubrication. While the ideal oil pressure ranges from 25-65 PSI, a reading over 80 PSI is considered too high and can result in engine damage.

Understanding the causes of high oil pressure is essential for maintaining the longevity of your engine.

Key Takeaways:

- High oil pressure can cause wear, damage, and even engine failure.

- Factors such as engine size, bore diameter, and oil viscosity affect oil pressure.

- Causes of high oil pressure include a malfunctioning oil pressure sending unit, dirty oil filter, blocked passages, relief valve malfunction, and the use of the wrong oil viscosity or quality.

- Regular maintenance, such as changing the oil filter and using the correct oil viscosity, can help prevent high oil pressure.

- Addressing oil pressure issues promptly is crucial to prevent engine damage and ensure the longevity of the engine.

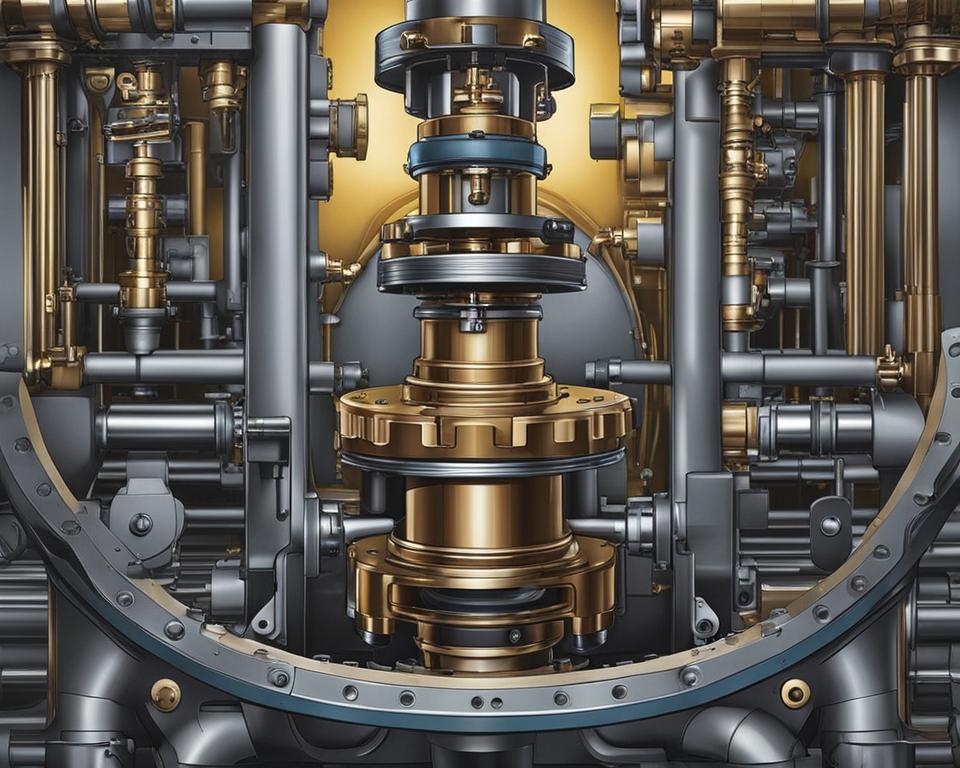

Causes of High Oil Pressure

High oil pressure in an engine can have various causes. Understanding these causes is crucial for maintaining the health and performance of your vehicle. The following factors can contribute to high oil pressure:

- Malfunctioning Oil Pressure Sending Unit: The oil pressure sending unit is responsible for measuring the oil pressure in the engine. If this unit malfunctions, it can provide inaccurate readings, leading to high oil pressure.

- Dirty or Contaminated Oil Filter: Over time, debris and contaminants can accumulate in the oil filter, restricting the flow of oil and causing increased pressure.

- Blocked Passages in the Engine: The engine’s passages carry oil to different components for lubrication. When these passages become blocked, oil flow is compromised, resulting in elevated oil pressure.

- Relief Valve Malfunction: The relief valve is designed to regulate oil pressure by releasing excess oil. If the relief valve fails to function properly, it can cause a buildup of pressure within the engine.

- Wrong Oil Viscosity or Quality: Using the wrong oil viscosity or poor-quality oil can disrupt the proper flow of oil through the engine, leading to increased pressure.

To visualize the causes of high oil pressure, refer to the table below:

| Causes of High Oil Pressure | Description |

|---|---|

| Malfunctioning Oil Pressure Sending Unit | Can provide inaccurate readings and contribute to high oil pressure. |

| Dirty or Contaminated Oil Filter | Debris and contaminants in the oil filter can restrict oil flow and increase pressure. |

| Blocked Passages in the Engine | Blocked passages prevent oil from flowing freely, causing heightened pressure. |

| Relief Valve Malfunction | A faulty relief valve can lead to excessive oil pressure. |

| Wrong Oil Viscosity or Quality | Using the wrong oil or poor-quality oil can disrupt oil flow and result in elevated pressure. |

Addressing these issues promptly is essential to prevent engine damage and ensure optimal performance. In the next sections, we’ll explore each cause in detail and provide insights on diagnosing and resolving these high oil pressure issues.

Oil Pressure Sending Unit Malfunction

The oil pressure sending unit plays a crucial role in measuring the oil pressure and controlling the oil pressure gauge on the dashboard.

It provides accurate readings, allowing the driver to monitor the oil pressure and ensure the engine’s proper lubrication.

However, if the oil gauge reading remains consistently high even after the engine has warmed up, it may indicate a malfunctioning oil pressure sending unit.

This issue can be diagnosed using a manual oil pressure tester. The manual oil pressure tester is a tool that allows you to measure the actual oil pressure in the engine.

By connecting the tester to the oil pressure sending unit’s location, you can compare the gauge’s readings on the dashboard to the manual tester’s readings.

If there is a significant difference between the two readings, it indicates a faulty oil pressure sending unit.

Diagnosing the oil pressure sending unit malfunction is essential as it ensures accurate oil pressure readings and prevents further complications.

If you are not comfortable performing the test yourself, it is recommended to consult a mechanic who can use a manual oil pressure tester and provide an accurate analysis.

Dirty or Contaminated Oil Filter

One of the common causes of high oil pressure is a dirty or contaminated oil filter. Over time, particles like dust, soot, rust, and gum can accumulate in the oil filter, causing it to become dirty and clogged.

When the oil filter is clogged, it restricts the flow of oil through the engine, leading to increased oil pressure.

Regularly changing the oil filter is crucial to prevent this issue. It is recommended to follow the manufacturer’s guidelines regarding the frequency of oil filter replacements.

By maintaining a clean and unclogged oil filter, you can ensure proper oil flow and prevent excessive oil pressure.

“A dirty oil filter can significantly impact the oil pressure and ultimately affect the engine’s performance and longevity. It is important to prioritize regular maintenance and replace the oil filter as recommended.”

To visually understand the impact of a dirty oil filter, refer to the image below:

Effects of a Dirty Oil Filter:

- Increased oil pressure

- Impaired oil flow

- Reduced engine performance

- Potential engine damage

Blocked Passages

The oil in your engine flows through a series of passages to reach all the parts that require lubrication.

These passages ensure that the engine’s components work smoothly and efficiently. However, over time, these passages can become blocked or clogged, hindering the proper flow of oil.

When the passages are blocked, the oil cannot reach its intended destinations, resulting in restricted oil flow.

This obstruction can disrupt the engine’s lubrication process, causing various issues such as increased friction and heat, which can lead to engine damage over time.

Blocked passages are often caused by the accumulation of debris, sludge, or contaminants in the engine.

This can happen due to factors like poor oil quality, inadequate maintenance, or extended periods without oil changes.

To rectify the problem of blocked passages and restore proper oil flow, it is necessary to clean out the passages. This can be done during routine engine maintenance and oil change procedures.

Mechanic services and specialized engine flushing products are available to help remove the accumulated debris and restore unrestricted oil flow.

“Blocked passages hinder the flow of oil, which is critical for engine lubrication. Regular maintenance and cleaning of these passages are essential to prevent potential engine damage.”

In severe cases, if the blocked passages are not addressed promptly, they can lead to increased oil pressure throughout the engine. This can cause oil leaks, reduced engine performance, and even engine failure.

Ensuring that the passages in your engine are clean and free from blockages is crucial for maintaining proper engine lubrication and preventing potential engine issues.

Next, we will discuss another common cause of high oil pressure: relief valve malfunction. Understanding the causes and remedies for relief valve issues will help you address high oil pressure problems effectively.

Relief Valve Malfunction

A relief valve plays a crucial role in maintaining the optimal oil pressure within an engine.

When the pressure exceeds a certain level, the relief valve is designed to open and release the excess oil, preventing excessive oil pressure and potential engine damage.

However, in the event of a relief valve malfunction, it may fail to open as intended, leading to excessive oil pressure. This can pose a serious risk to engine safety and performance.

Excessive oil pressure can cause various problems, including increased stress on engine components, reduced engine efficiency, and potential oil leaks.

If left unaddressed, relief valve failure can lead to severe engine damage and the need for costly repairs.

To mitigate the risks associated with relief valve malfunction, regular maintenance and inspections are essential.

Engine oil should be checked regularly, and any signs of excessive pressure, such as oil leaks or unusual engine noises, should be promptly addressed.

“Relief valve malfunction can lead to excessive oil pressure, posing a serious risk to engine safety and performance.”

Signs of Relief Valve Malfunction

Identifying a relief valve malfunction can be challenging, as the symptoms may vary depending on the specific engine and its operating conditions. However, some common signs include:

- Consistently high oil pressure readings

- Unusual engine sounds, such as knocking or ticking

- Oil leaks or excessive oil consumption

- Reduced engine performance or power

Addressing Relief Valve Malfunction

If relief valve malfunction is suspected, it is recommended to consult a professional mechanic or technician for a thorough inspection and diagnosis. They will be able to determine if the relief valve needs to be repaired or replaced.

It is important not to overlook relief valve issues, as they can significantly impact engine safety and longevity.

Regular maintenance, including oil changes and filter replacements, can help prevent relief valve malfunction and ensure optimal engine performance.

Summary

Relief valve malfunction can lead to excessive oil pressure, posing a risk to engine safety, performance, and longevity. Regular maintenance and inspections are crucial to identify and address relief valve issues promptly.

By maintaining the proper functioning of the relief valve, engine owners can ensure optimal oil pressure and protect their engines from potential damage.

Oil Quality and Viscosity

The viscosity (thickness) and quality of the oil used in the engine play a crucial role in maintaining optimal oil pressure.

Using the wrong viscosity grade or low-quality oil can lead to increased resistance, resulting in higher oil pressure.

Furthermore, engine temperature fluctuations can also affect the viscosity of the oil, which can cause variations in oil pressure.

When it comes to oil viscosity, it is essential to select the right grade recommended by the manufacturer. Using oil with a lower viscosity than recommended can lead to inadequate lubrication, increased friction, and higher oil pressure.

On the other hand, using oil with a higher viscosity can cause sluggish oil flow, resulting in reduced oil pressure.

The quality of the oil is equally important. Low-quality oil may contain impurities, additives, or contaminants that can hinder the smooth flow of oil within the engine. This can lead to increased resistance, resulting in elevated oil pressure.

It is crucial to choose high-quality oil that meets the required standards and specifications.

Engine temperature also plays a significant role in oil viscosity and, consequently, oil pressure. As the engine temperature increases, the oil becomes thinner, which can lead to a decrease in oil pressure.

Conversely, in colder temperatures, the oil thickens, resulting in higher oil pressure.

Therefore, it is vital to use the right oil viscosity and quality for your specific engine and ensure that it is suitable for the prevailing weather conditions.

Consult your vehicle’s manual or seek professional advice to determine the appropriate oil grade and quality to maintain optimal oil pressure and engine performance.

Key Points:

- The viscosity and quality of the oil impact oil pressure.

- Using the wrong viscosity grade or low-quality oil can lead to higher oil pressure.

- Engine temperature affects oil viscosity, which can cause variations in oil pressure.

- Choose the right oil viscosity and quality for your engine, considering manufacturer recommendations and prevailing weather conditions.

Clogged Oil Passages

As oil flows through the engine, it can carry debris that gradually accumulates in the oil passages.

Over time, this buildup can lead to clogged oil passages, restricting the flow of oil to various engine components.

This restriction hinders proper lubrication and disrupts the oil’s ability to cool, resulting in increased friction and heat.

As a consequence, the engine may experience high oil pressure, which can have detrimental effects on its performance and longevity.

Clogged oil passages can cause significant engine damage if left unaddressed. The restricted oil flow deprives crucial engine components, such as bearings and camshafts, of the necessary lubrication, leading to excessive wear and tear. Without adequate lubrication, these components can suffer from increased friction and heat, which can ultimately result in premature failure.

Furthermore, the lack of sufficient lubrication due to clogged oil passages can lead to a variety of lubrication issues within the engine.

This can result in increased friction between moving parts, inadequate cooling, and increased operational stress.

Over time, these issues can further compound and contribute to engine damage, reducing its overall performance and reliability.

To mitigate the risks associated with clogged oil passages, regular maintenance is crucial. This includes conducting regular oil changes, using high-quality oil filters, and employing proper flushing techniques to remove any accumulated debris.

Additionally, periodic inspection and cleaning of the oil passages can help ensure continuous oil flow and prevent the development of blockages.

Effects of Clogged Oil Passages:

- Restricted oil flow

- Increased friction and heat

- Poor lubrication

- Excessive wear and tear

- Premature engine failure

By addressing clogged oil passages promptly, engine owners can prevent lubrication issues, protect against potential engine damage, and maintain optimal engine performance.

Regular maintenance practices and the use of high-quality lubricants are essential in promoting the longevity and reliability of an engine.

Oil Pressure Switch Malfunction

The oil pressure switch plays a crucial role in ensuring accurate oil pressure readings. When this switch malfunctions, it can provide incorrect readings, leading to confusion and potential damage if not addressed promptly.

One common issue with the oil pressure switch is a faulty sensor. This can occur due to wear and tear or electrical malfunctions, resulting in inaccurate readings.

A faulty sensor may indicate high oil pressure even when the pressure is within the normal range, causing unnecessary concerns for vehicle owners.

Incorrect oil pressure readings can lead to unnecessary maintenance or even engine damage if left unattended. It is important to identify and resolve a malfunctioning oil pressure switch to ensure accurate monitoring of oil pressure levels.

A replacement of the faulty oil pressure switch is the most viable solution to rectify this issue. By replacing the malfunctioning switch with a new one, accurate oil pressure readings can be restored, providing peace of mind to vehicle owners.

In summary, a malfunctioning oil pressure switch can result in incorrect oil pressure readings, potentially causing unnecessary maintenance or failure to address actual pressure issues.

Replacing the faulty switch with a new one is crucial to ensure accurate monitoring of oil pressure levels and maintain the health of the engine.

FAQ

What causes high oil pressure?

High oil pressure can be caused by various factors, including issues with the oil pressure sending unit, oil filter, passages, relief valve, and oil quality.

How does the oil pressure sending unit malfunction contribute to high oil pressure?

The oil pressure sending unit measures the oil pressure and controls the oil pressure gauge on the dashboard.

If the unit malfunctions, it may provide incorrect readings, indicating high oil pressure even when the pressure is within the normal range.

What is the impact of a dirty or contaminated oil filter on oil pressure?

Over time, particles can accumulate in the oil filter, causing it to become dirty and clogged. This restricts the flow of oil and increases oil pressure.

How do blocked passages affect oil pressure?

The oil flows through a series of passages in the engine, and if these passages become blocked or clogged, the oil cannot flow effectively, leading to higher oil pressure.

What role does a relief valve malfunction play in high oil pressure?

The relief valve is designed to release oil when the pressure exceeds a certain level. If the valve malfunctions, it may not open as intended, causing excessive oil pressure.

How does oil quality and viscosity impact oil pressure?

Using the wrong viscosity or poor-quality oil can increase resistance and result in higher oil pressure. Additionally, engine temperature affects oil viscosity, which can cause variations in oil pressure.

How do clogged oil passages contribute to high oil pressure?

As oil flows through the engine, it can carry debris that can accumulate in the oil passages over time. This buildup can lead to clogged oil passages, restricting oil flow and causing high oil pressure.

What is the role of the oil pressure switch in high oil pressure?

The oil pressure switch is responsible for sending signals to the oil pressure gauge, and if it malfunctions, it can provide incorrect readings and indicate high oil pressure even when the pressure is within the normal range.

How can high oil pressure be prevented or addressed?

Regular maintenance, such as changing the oil filter and using the correct oil viscosity, can help prevent high oil pressure.

It is important to address any oil pressure issues promptly to prevent engine damage and ensure the longevity of the engine.

Conclusion

In conclusion, high oil pressure can be caused by various factors, including issues with the oil pressure sending unit, oil filter, passages, relief valve, and oil quality.

It is crucial to address these issues promptly to prevent engine damage and ensure the longevity of the engine.

Performing preventative maintenance is key to avoiding oil pressure problems. Regularly changing the oil filter is essential to prevent it from becoming dirty and clogged, which can restrict oil flow and lead to high oil pressure.

Additionally, using the correct oil viscosity for your engine and ensuring its quality will help maintain optimal oil pressure.

By staying on top of preventative maintenance and addressing any oil pressure issues, you can mitigate the risk of engine damage and prolong the life of your engine.

Taking these steps will not only keep your engine running smoothly but also save you from costly repairs down the line. Remember, a well-maintained engine is a reliable engine.