Iron and steel are two materials often used interchangeably, but they have some key differences that are important to understand. This article will delve into the dissimilarities between iron and steel, exploring their composition, properties, applications, and more.

Key Takeaways:

- Iron is an element, while steel is an alloy of iron and carbon.

- Steel is stronger and tougher than iron due to the addition of carbon and other elements.

- Iron is commonly used in the production of metals and alloys, magnets, and fabricated metal products.

- Steel is more versatile and widely used in buildings, infrastructure, mechanical equipment, and the automotive industry.

- Steel is more durable and has better corrosion resistance compared to iron.

History of Iron and Steel Production

The manufacturing of iron and steel has a rich and fascinating history that spans thousands of years. From ancient civilizations to modern industrial processes, the production of these metals has played a pivotal role in the development of human civilization.

The story of iron begins in prehistoric times, with evidence of iron beads found in ancient Egyptian tombs dating back to 3,500 BC. The discovery of iron ore and the development of iron smelting techniques led to the Iron Age, a period characterized by the widespread use of iron tools and weapons.

Over time, the production of iron evolved, with different cultures and regions employing various techniques and processes. Cast iron, for example, first appeared in China during the 5th century BC and quickly became a popular material due to its strength and versatility. As civilizations advanced, so did the methods of iron production, culminating in the development of blast furnaces and the use of coal as a fuel source.

The production of steel, on the other hand, began around 4,000 years ago. Ancient civilizations such as the Hittites and the Egyptians were known to have produced small amounts of steel through a process known as carburization, where iron is heated in the presence of carbon-rich materials. However, it was not until the 19th century that steel production truly revolutionized with the advent of the Bessemer process and the open-hearth furnace, leading to mass production and widespread use of this versatile material.

| Year | Advancement in Iron Production | Advancement in Steel Production |

|---|---|---|

| 3500 BC | Iron beads found in ancient Egyptian tombs | – |

| 5th century BC | Cast iron production begins in China | – |

| 19th century | Development of blast furnaces | Bessemer process and open-hearth furnace |

Today, iron and steel production is a massive industry, with countries around the world investing significant resources into the extraction of iron ore, the refining of iron, and the creation of steel. The iron and steel industry plays a critical role in infrastructure development, manufacturing, and construction, providing the materials necessary for buildings, bridges, machinery, and various consumer goods.

As technology continues to advance, the methods and processes used in iron and steel production are also evolving. From the ancient smelting techniques to the modern electric arc furnaces, the history of iron and steel is a testament to human ingenuity and the constant pursuit of better and more efficient methods of metal production.

Properties of Iron

Iron possesses unique properties that make it a valuable material in various applications. Understanding these properties is essential for determining the suitability of iron for specific uses.

1. Physical Properties of Iron

Iron is a silver-gray metal with a density of 7.87 grams per cubic centimeter. It has a melting point of 1,538 degrees Celsius and a boiling point of 2,862 degrees Celsius. Pure iron is soft and malleable, allowing it to be easily shaped and formed. However, its low strength and brittleness limit its use in certain applications.

2. Mechanical Properties of Iron

The mechanical properties of iron can be improved by alloying it with other elements. For example, cast iron is a type of iron alloyed with carbon and silicon, which enhances its hardness and wear resistance. Wrought iron, produced by refining cast iron, has better tensile strength and ductility. These mechanical properties make iron alloys suitable for manufacturing structural components, pipes, and machinery.

3. Magnetic Properties of Iron

Iron is highly magnetic and can be easily magnetized. This property makes it useful in the production of magnets for various applications, including electrical motors, generators, and magnetic storage devices.

4. Corrosion Resistance of Iron

Pure iron is prone to corrosion when exposed to moisture and oxygen. It forms a reddish-brown oxide known as rust. To improve its corrosion resistance, iron is often coated with protective layers, such as paint or zinc. Alloying iron with elements like chromium can also enhance its corrosion resistance, as seen in stainless steel.

| Property | Description |

|---|---|

| Physical Properties | – Silver-gray metal – Density: 7.87 g/cm3 – Melting point: 1,538 °C – Boiling point: 2,862 °C |

| Mechanical Properties | – Brittleness – Low strength – Alloying improves properties |

| Magnetic Properties | – Highly magnetic – Used in magnets and magnetic devices |

| Corrosion Resistance | – Prone to rust – Coating and alloying enhance resistance |

Properties of Steel

Steel, as an alloy of iron and carbon, possesses unique properties that make it a highly versatile and sought-after material in various industries. Its distinct characteristics set it apart from pure iron and contribute to its widespread use in construction, infrastructure, and mechanical equipment.

Strength and Durability: One of the key advantages of steel is its exceptional strength and durability. The addition of carbon and other alloying elements enhances its tensile strength, making it resistant to deformation and able to withstand heavy loads and extreme conditions.

Corrosion Resistance: Steel exhibits superior corrosion resistance compared to pure iron. Through the use of protective coatings such as zinc or galvanized finishes, steel can be effectively shielded from rust and other forms of oxidation. Additionally, alloying elements like chromium and nickel further enhance its resistance to corrosion, making it suitable for use in marine environments and other settings prone to moisture.

Versatility: Steel’s versatility stems from its ability to be shaped, bent, and molded into various forms. This characteristic allows for creative and efficient design options, enabling engineers and architects to bring their innovative concepts to life. Whether it’s in the construction of skyscrapers, manufacturing of automotive components, or fabrication of intricate machinery, steel offers unparalleled versatility.

Heat Conductivity: Steel possesses good thermal conductivity, making it an ideal choice for applications requiring heat transfer. This property enables efficient heat exchange in various industries, such as heating and cooling systems, power generation, and manufacturing processes.

Comparison of Iron and Steel Properties

| Property | Iron | Steel |

|---|---|---|

| Strength | Low | High |

| Durability | Less durable, prone to rust | High durability, resistant to corrosion |

| Versatility | Limited | Highly versatile, can be molded and shaped |

| Heat Conductivity | Good | Good |

These properties highlight the significant differences between iron and steel, emphasizing the advantages that steel offers in terms of strength, durability, versatility, and corrosion resistance. While iron has its own uses and applications, steel’s superior properties have made it the material of choice for a wide range of industries.

Difference in Applications

Iron and steel have different applications due to their distinct properties. Steel, with its strength and versatility, is widely used in various industries and sectors.

Building and Construction

Steel is an essential material in the building and construction industry. It is used in the construction of high-rise buildings, bridges, and infrastructure due to its high strength-to-weight ratio. Steel beams and columns provide structural support, while steel reinforcement bars (rebar) are used in concrete construction to enhance its tensile strength.

Iron, on the other hand, is commonly used in the construction industry for smaller-scale projects. It is often found in fencing, gates, and ornamental features due to its malleability and aesthetic appeal.

Automotive Industry

The automotive industry heavily relies on steel for its production. Steel is used in the manufacturing of car bodies, frames, and various components due to its strength, durability, and crashworthiness. Advanced high-strength steels (AHSS) are employed to enhance vehicle safety while reducing weight, improving fuel efficiency, and reducing emissions.

Iron, although not as commonly used in automobiles, can be found in certain components such as engine blocks and cylinder heads. Cast iron is known for its exceptional heat retention, making it suitable for engine parts that require high thermal stability.

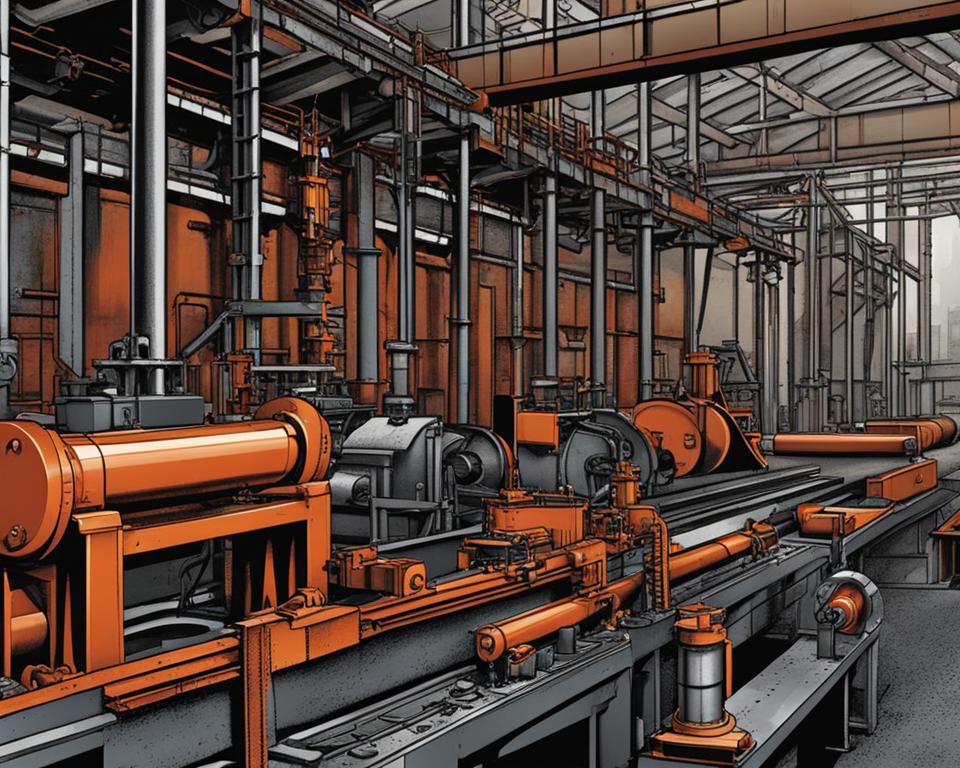

Industrial Equipment

Steel is extensively used in the manufacturing of industrial equipment and machinery. Its strength and resistance to corrosion make it ideal for heavy-duty applications. Steel pipes, tanks, and structures are commonly found in industries such as oil and gas, mining, and manufacturing.

Iron, with its magnetic properties, finds applications in the production of electromagnets, electric motors, and transformers. It is also used in the fabrication of machinery components where its lower cost and availability make it a viable option.

| Applications | Iron | Steel |

|---|---|---|

| Building and Construction | Fencing, gates, ornamental features | High-rise buildings, bridges, infrastructure |

| Automotive Industry | Engine blocks, cylinder heads | Car bodies, frames, components |

| Industrial Equipment | Electromagnets, electric motors, transformers | Pipes, tanks, structures |

Difference in Durability

When it comes to durability, steel outshines iron in many aspects. Steel is known for its remarkable strength and toughness, making it more resistant to wear and tear compared to iron. It can withstand extreme conditions, including severe winds and high temperatures, without losing its structural integrity. On the other hand, iron is a softer metal and is more prone to damage and deformation. It is also porous, which makes it susceptible to mold, rust, and other types of oxidation. These factors can significantly reduce the lifespan of iron-based materials.

In construction and infrastructure projects where long-term durability is crucial, steel is the go-to material. Its superior durability ensures that buildings, bridges, and other structures can withstand the test of time and the elements. Moreover, steel’s resistance to corrosion and other forms of degradation makes it a reliable choice in environments with high humidity or exposure to corrosive substances. Iron, although less durable, is still utilized in various applications where its specific properties are required, such as the production of metals and alloys.

Steel’s durability is crucial in industries like aerospace and automotive, where safety and reliability are paramount. Its exceptional strength and resistance to fatigue ensure that critical components can withstand the stresses and strains imposed on them, even under extreme conditions.

It is worth noting that the durability of both iron and steel can be further enhanced through proper maintenance and protective measures. Regular inspections, cleaning, and the application of protective coatings can help prolong the lifespan of iron and steel structures. By addressing any signs of corrosion or damage early on, the integrity of the materials can be preserved, ensuring their continued performance over time.

Comparison of Durability between Iron and Steel

| Property | Iron | Steel |

|---|---|---|

| Durability | Lower | Higher |

| Resistance to wear and tear | Lower | Higher |

| Resistance to deformation | Lower | Higher |

| Resistance to corrosion | Lower | Higher |

The table above summarizes the key differences in durability between iron and steel. Steel demonstrates higher durability, with greater resistance to wear and tear, deformation, and corrosion compared to iron. These properties make steel the preferred choice in numerous industries and applications where longevity and reliability are essential.

Difference in Corrosion Resistance

When it comes to corrosion resistance, there is a noticeable difference between iron and steel. Both materials are susceptible to rust when exposed to water and air, but steel has the advantage of being able to be coated with protective layers. These coatings, such as zinc or other protective coatings, act as a barrier between the steel and the elements, preventing corrosion from occurring. The presence of alloying elements in steel also contributes to its corrosion resistance, making it a preferred choice in environments where rusting is a concern.

On the other hand, iron, being a pure element, is more prone to oxidation and requires additional protection to prevent rust. Without proper coatings or treatments, iron can quickly deteriorate when exposed to moisture and air. This is why iron is commonly used as a primary ingredient in metals and alloys rather than as a standalone material in applications where corrosion resistance is crucial.

Overall, the difference in corrosion resistance between iron and steel highlights the importance of selecting the right material for specific projects. While steel offers better protection against rust and corrosion, iron still plays a significant role in various industries where its unique properties are desired.

Conclusion

Iron and steel may often be used interchangeably, but they are two distinct materials with different properties and applications. Steel, as an alloy of iron and carbon, offers greater strength, toughness, and versatility compared to iron. It is widely utilized in various industries, thanks to its excellent mechanical properties and corrosion resistance.

On the other hand, iron plays a crucial role as a primary ingredient in metals and alloys. While not as durable as steel and prone to corrosion, iron remains essential in the production of magnets, fabricated metal products, and other applications.

Understanding the difference between iron and steel is vital when selecting the appropriate material for different projects. Steel’s superior strength and durability make it a top choice for construction, infrastructure, and mechanical equipment. Meanwhile, iron’s unique properties and affordability make it valuable in specific applications where its limitations can be mitigated.

FAQ

What is the difference between iron and steel?

Iron is an element, while steel is an alloy of iron and carbon. Steel is stronger and tougher than iron due to the addition of carbon and other elements.

When did iron and steel production begin?

The production of iron dates back thousands of years, with early examples of iron beads found in Egypt dating back to 3,500 BC. Steel production began around 4,000 years ago.

What are the properties of iron?

Iron is a soft and brittle metal with excellent thermal and electrical conductivity. It is prone to oxidation and is not very strong.

What are the properties of steel?

Steel is stronger and tougher than iron. It has higher yield and tensile strength, making it suitable for various applications. Steel can also contain other elements such as chromium and nickel, which enhance its properties.

How are iron and steel used?

Iron is commonly used in the production of metals and alloys, magnets, and fabricated metal products. Steel is used in buildings and infrastructure, mechanical equipment, and the automotive industry.

Which is more durable, iron or steel?

Steel is more durable than iron. Iron is porous and susceptible to mold, rust, and other forms of oxidation, which can reduce its lifespan and structural integrity.

Do iron and steel rust?

Yes, both iron and steel can rust when exposed to water and air. However, steel can be coated with protective coatings to prevent corrosion.

Why is steel more resistant to corrosion than iron?

The presence of alloying elements in steel contributes to its corrosion resistance. Iron, being a pure element, is more prone to oxidation and requires additional protection.