Are you confused about the difference between screws and bolts? While they may look similar, these two fasteners have distinct characteristics and applications. Understanding the dissimilarities is crucial for selecting the right type of fastener for your project. Let’s dive into the details.

Key Takeaways:

- Screws are used to assemble threaded objects, while bolts are used for unthreaded objects, typically with the use of a nut.

- Screws can create their own threads, while bolts require a nut to secure them in place.

- Bolts provide stronger doweling against sideways forces, making them suitable for bolted joints.

- Screws come in different types, such as wood screws and sheet metal screws, with various head shapes like pan and round.

- Understanding the characteristics, uses, and differences between screws and bolts is essential for selecting the right fastener for your application.

Characteristics and Uses of Screws

Screws are an essential component in various applications due to their unique characteristics and versatile uses. Unlike bolts, screws are externally threaded fasteners that can be inserted into holes in assembled parts and tightened or released by torquing the head. They mate with preformed internal threads or create their own threads during installation.

Screws offer several advantages, including the ability to be tightened using a screwdriver or driver bit without the need for additional nuts. They are typically shorter than the width of the material being screwed into, ensuring a flush finish on the other side. This makes screws suitable for applications where a protruding fastener is undesirable. Self-tapping screws are also available, which can create their own threads as they are driven into the material.

Screws find applications in various industries, including woodworking, construction, and electronics. Different types of screws serve specific purposes, such as chipboard screws for wood panels and drywall screws for attaching drywall sheets. Their versatility, ease of use, and ability to create strong and secure fastenings make screws a popular choice in numerous projects.

Screw Characteristics:

- Externally threaded fasteners

- Can be tightened or released by torquing the head

- Mate with preformed internal threads or create their own threads

- Shorter in length compared to the width of the material

- No additional nuts required for tightening

- Can be self-tapping

Common Uses of Screws:

- Woodworking projects

- Construction applications

- Electronics assembly

- Drywall installation

Screws offer a reliable and efficient solution for securing different materials and components.

Characteristics and Uses of Bolts

Bolts are externally threaded fasteners designed for insertion through holes in assembled parts. They are usually used with a nut and are tightened or released by torquing the nut. Bolts are not usually threaded all the way along their shank, unlike screws that are fully threaded. The unthreaded portion of bolts, known as the grip length, provides added strength against shear forces. The length of bolts is typically longer than the width of the material they are being fastened to, allowing them to protrude through and screw into the nut on the other side. Bolts are often fastened using a spanner or other tools that grip the head while the nut is tightened. They are commonly used in applications where strong, secure joints are required, such as in structural steel connections or automotive assemblies.

Characteristics of Bolts:

- Externally threaded fasteners

- Used with a nut for assembly

- Not fully threaded

- Have an unthreaded grip length for added strength

- Length is longer than the material width

- Protrude through and screw into the nut

- Fastened using a spanner or similar tool

Uses of Bolts:

- Creating strong and secure joints

- Connecting structural steel members

- Assembling automotive components

- Joining machinery and equipment

- Securing heavy-duty constructions

Differences in Construction Materials

Both screws and bolts are available in a range of materials to suit different applications. The most commonly used material for both screws and bolts is steel, which accounts for up to 90% of all bolts manufactured. Steel bolts offer strength and durability, making them suitable for a wide range of applications. Stainless steel is also a popular choice due to its corrosion resistance. Bolts and screws can also be made from materials like bronze, brass, and nylon, each offering specific properties for different environments or requirements. The choice of construction material depends on factors such as strength, corrosion resistance, and compatibility with the materials being fastened.

For a comprehensive comparison of the different materials used in screws and bolts, refer to the table below:

| Material | Properties | Applications |

|---|---|---|

| Steel | High strength, durability | General-purpose, automotive, construction |

| Stainless Steel | Corrosion resistance | Marine, food industry, outdoor applications |

| Bronze | Low friction | Mechanical, electrical, marine |

| Brass | Corrosion resistance, aesthetic appeal | Decorative, furniture, plumbing |

| Nylon | Electrical insulation, lightweight | Electronics, aerospace, automotive |

As shown in the table, each material offers unique properties that make it suitable for specific applications. When selecting the right construction material for screws and bolts, it is essential to consider the specific requirements of the project, such as the environment, load-bearing capacity, and compatibility with other materials.

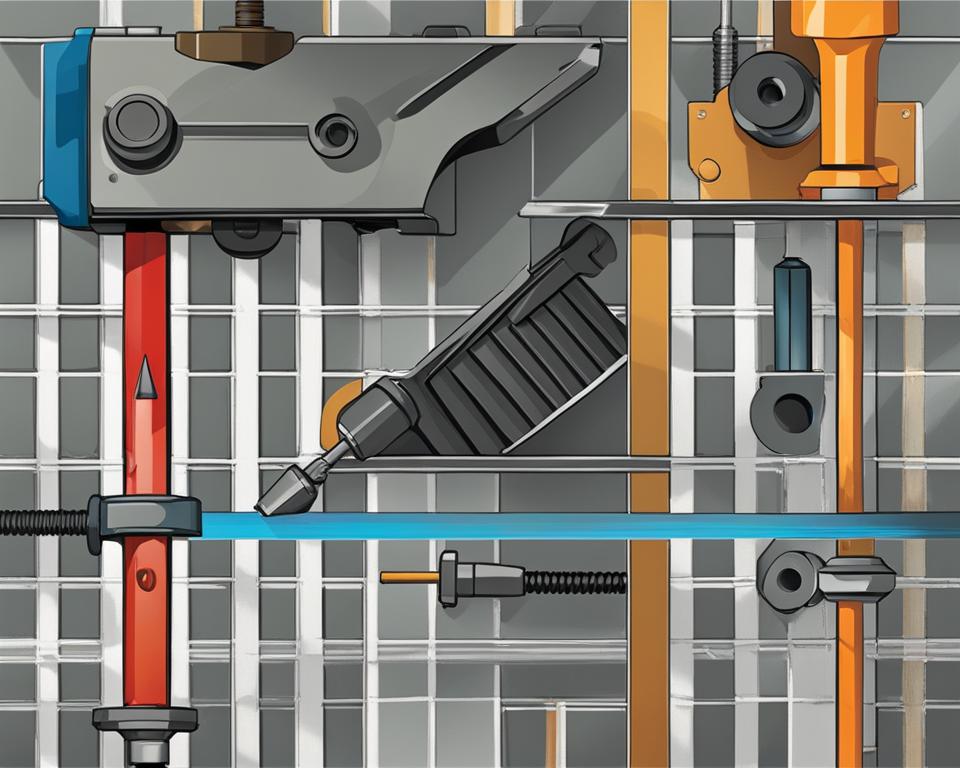

Different Head Shapes

Screws and bolts come in various head shapes, each serving different purposes and offering unique advantages. Understanding the different head shapes is important for selecting the right fastener for your specific application.

Pan Head Screws

Pan head screws have a flat, circular head with a slightly rounded top. This head shape provides a larger surface area for distributing pressure, making them suitable for applications where a flush finish is not required. Pan head screws are commonly used in electrical wiring, automotive assembly, and electronics.

Button Head Screws

Button head screws have a low-profile, rounded head with a flat top. This head shape reduces the risk of injury or damage, as there are no sharp edges or corners. Button head screws are often used in furniture assembly, cabinetry, and decorative applications.

Round Head Screws

Round head screws have a smooth, rounded surface, making them easy to clean and resistant to dirt buildup. This head shape is commonly used in applications where hygiene is important, such as food processing equipment and medical devices.

Flat Head Screws

Flat head screws have a countersunk head that sits flush with the surrounding surface when fully tightened. This head shape provides a smooth, finished appearance and minimizes the risk of snagging or catching on objects. Flat head screws are often used in woodworking, furniture construction, and finishing work.

Hex Head Bolts

Hex head bolts have a six-sided head shape, known as a hexagon. This head shape allows for easy gripping and torque application using a spanner or wrench. Hex head bolts are commonly used in structural steel connections, machinery assembly, and automotive applications.

Table: Head Shape Comparison

| Head Shape | Advantages | Common Applications |

|---|---|---|

| Pan Head Screws | Large surface area for distributing pressure | Electrical wiring, automotive assembly, electronics |

| Button Head Screws | Low-profile, rounded head with no sharp edges | Furniture assembly, cabinetry, decorative applications |

| Round Head Screws | Smooth, rounded surface for easy cleaning | Food processing equipment, medical devices |

| Flat Head Screws | Flush finish, minimizes snagging or catching | Woodworking, furniture construction, finishing work |

| Hex Head Bolts | Easy gripping and torque application | Structural steel connections, machinery assembly, automotive |

Conclusion

In summary, understanding the difference between screws and bolts is crucial for selecting the right fastener for your needs. While they may appear similar, screws and bolts serve distinct purposes and have unique characteristics.

Screws are primarily used for assembling threaded objects, and they can create their own threads during installation. They are often employed in applications where a flush finish or self-tapping capability is required.

On the other hand, bolts are designed for assembling unthreaded objects and typically require the use of a nut. They are commonly utilized to create stronger, bolted joints and are often found in structural steel connections or automotive assemblies.

By understanding the differences in function, uses, and characteristics between screws and bolts, you can ensure that you choose the right fastener for your specific application, whether it be woodworking, construction, electronics, or any other industry.

FAQ

What is the difference between a screw and a bolt?

The fundamental difference is that screws are used to assemble threaded objects, while bolts are used to assemble unthreaded objects with the use of a nut.

Can screws create their own threads?

Yes, screws can make their own threads during installation.

Do bolts require a nut to secure them in place?

Yes, bolts require a nut to secure them in place.

What are some common types of bolts?

Some common types of bolts include anchor bolts, hex bolts, and U bolts.

What are some common types of screws?

Some common types of screws include wood screws and sheet metal screws.

How are screws typically tightened?

Screws are typically tightened using a screwdriver or driver bit.

How are bolts typically tightened?

Bolts are typically tightened using a spanner or other tools that grip the head while the nut is tightened.

What materials are bolts and screws commonly made from?

Both bolts and screws are commonly made from materials like steel and stainless steel.

What are some common head shapes for screws and bolts?

Common head shapes for screws include pan, button, round, and flat. For bolts, the most common head shape is hex or hexagon.

What factors should be considered when selecting construction materials for bolts and screws?

Factors such as strength, corrosion resistance, and compatibility with the materials being fastened should be considered.

![Ray Dalio Quotes [Principles, Life, Investment]](https://tagvault.org/wp-content/uploads/2023/04/Screen-Shot-2023-04-19-at-7.57.49-PM.png)