Welcome to our comprehensive troubleshooting guide for gas control valve failures. Gas control valves are essential for the proper functioning of gas appliances, but they can sometimes encounter problems that affect their performance. In this guide, we will discuss common issues with gas control valves, provide installation tips, and offer troubleshooting advice specifically for Honeywell gas control valves. Whether you’re dealing with a malfunctioning gas valve in a water heater or furnace, this guide has you covered.

Key Takeaways:

- Gas control valve problems can cause issues with the proper functioning of gas appliances.

- Improper installation and unsuitable environmental conditions are common causes of gas control valve failures.

- Proper installation techniques can help prevent future issues with gas control valves.

- The LED indicator on Honeywell gas control valves provides valuable troubleshooting information.

- Consulting a professional technician may be necessary for complex gas control valve problems.

Common Issues with Gas Control Valves

Gas control valves, particularly Honeywell gas control valves, can experience various common problems. These issues often arise due to improper installation or unsuitable environmental conditions. Additionally, new regulations for backdrafting have contributed to the occurrence of these problems. Understanding these common issues is essential for effective troubleshooting and resolution of gas control valve problems.

Improper installation: One of the leading causes of gas control valve problems is improper installation. If the valve is not installed correctly, it can result in issues such as gas leaks, erratic temperature control, or even valve failure. It is crucial to follow the manufacturer’s instructions and guidelines for proper installation to avoid these problems.

Unsuitable environmental conditions: Gas control valves can be affected by the surrounding environment. Factors such as excessive moisture, extreme temperatures, or exposure to corrosive chemicals can impact the valve’s performance and potentially lead to malfunctioning. Ensuring that the environment is suitable for the gas control valve is essential to prevent problems.

New regulations for backdrafting: Backdrafting refers to the reverse flow of combustion gases into the living space, which can occur due to ventilation issues. Recent regulations aimed at improving safety have resulted in changes to venting requirements. These changes can sometimes cause problems with gas control valves, particularly if the venting system is not properly designed or if there are issues with backdrafting. Understanding these regulations and ensuring compliance can help prevent valve problems.

By being aware of these common issues with gas control valves, homeowners can take proactive measures to address and prevent problems. Troubleshooting gas control valve problems requires a systematic approach, which will be discussed in subsequent sections of this troubleshooting guide.

Common Issues with Gas Control Valves:

| Issue | Cause | Possible Solution |

|---|---|---|

| Gas leaks | Improper installation or faulty valve | Check for leaks and repair or replace faulty valve |

| Erratic temperature control | Malfunctioning thermostat or sensor | Calibrate or replace thermostat or sensor |

| Valve failure | Excessive wear and tear or manufacturing defect | Replace the faulty gas control valve |

Installation Tips for Gas Control Valves

Proper installation is crucial to ensure the smooth operation and longevity of gas control valves. Following the recommended installation guidelines can help prevent issues down the line. Here are some gas control valve installation tips:

Ventilation Considerations

When installing gas control valves, proper ventilation is essential to maintain safe and efficient operation. The vent should have a sufficient rise before the first elbow to allow for proper air circulation. This ensures that the combustion byproducts are adequately vented out of the system. By following ventilation guidelines, you can minimize the risk of backdrafting and related problems.

Connector Rise and Vent Size

If your unit is common vented and has a connector rise of less than 3 feet, it is advisable to use a larger vent size. This will help prevent any restriction in airflow, ensuring optimal performance of the gas control valve. A larger vent size can prevent issues such as insufficient gas flow and pressure drop, which can lead to poor combustion and potential valve failure.

| Installation Tip | Benefits |

|---|---|

| Provide sufficient vent rise before the first elbow | Prevents backdrafting and ensures proper air circulation |

| Use a larger vent size for units with a connector rise of less than 3 feet | Prevents airflow restriction and optimizes gas control valve performance |

By following these gas control valve installation tips, you can minimize the risk of future issues and ensure optimal performance of your gas-powered appliances. Remember, proper installation is the first step towards a safe and efficient gas control valve system.

Troubleshooting Honeywell Gas Control Valves

In order to effectively troubleshoot gas control valves, it is important to understand the valuable information that can be obtained from the LED indicator on Honeywell gas control valves. By interpreting the different flash codes, specific issues with the valve can be identified, such as the pilot not being lit, thermopile low voltage, temperature exceeding safe limits, sensor failure, or gas control valve failure.

Based on the issue indicated by the flash code, appropriate steps can be taken to resolve the problem. Some troubleshooting actions that may be necessary include:

- Checking wiring connections: Ensuring that all the wiring connections are secure and properly connected is essential in addressing various gas control valve issues. Loose or faulty connections can lead to improper functioning of the valve.

- Replacing the thermopile: If the flash code indicates low voltage, it may be necessary to replace the thermopile. The thermopile is responsible for generating the electrical energy required to power the gas control valve.

- Adjusting thermostat temperature: In situations where the temperature has exceeded safe limits, adjusting the thermostat temperature can help prevent further issues. By setting the appropriate temperature, the gas control valve can operate within its designed parameters.

- Replacing the gas control valve: In some cases, the flash code may indicate a complete failure of the gas control valve. In such instances, replacing the valve is necessary to restore proper functionality to the gas appliance.

By following these troubleshooting steps and utilizing the valuable information provided by the LED indicator on Honeywell gas control valves, homeowners can effectively address gas control valve issues and prevent further failures.

Seeking Professional Assistance for Gas Control Valve Issues

While troubleshooting can resolve many gas control valve issues, there are times when professional assistance is necessary. Experienced water heater technicians have the knowledge and expertise to accurately diagnose and address complex problems. It is advisable to consult a professional if troubleshooting steps have been followed without success. Regular maintenance of gas control valves is also important to ensure their proper functioning and prevent issues in the future.

Gas control valve maintenance tips:

- Ensure regular inspection of gas control valves

- Clean and remove debris from valve components

- Check for and repair any leaks

- Monitor gas pressure levels

- Verify proper venting and ventilation

If you’re experiencing persistent issues or unsure about handling gas control valve problems on your own, it’s best to trust the expertise of a professional. They can assess the situation, provide accurate diagnoses, and offer effective solutions to ensure the safety and optimal performance of your gas-powered appliances.

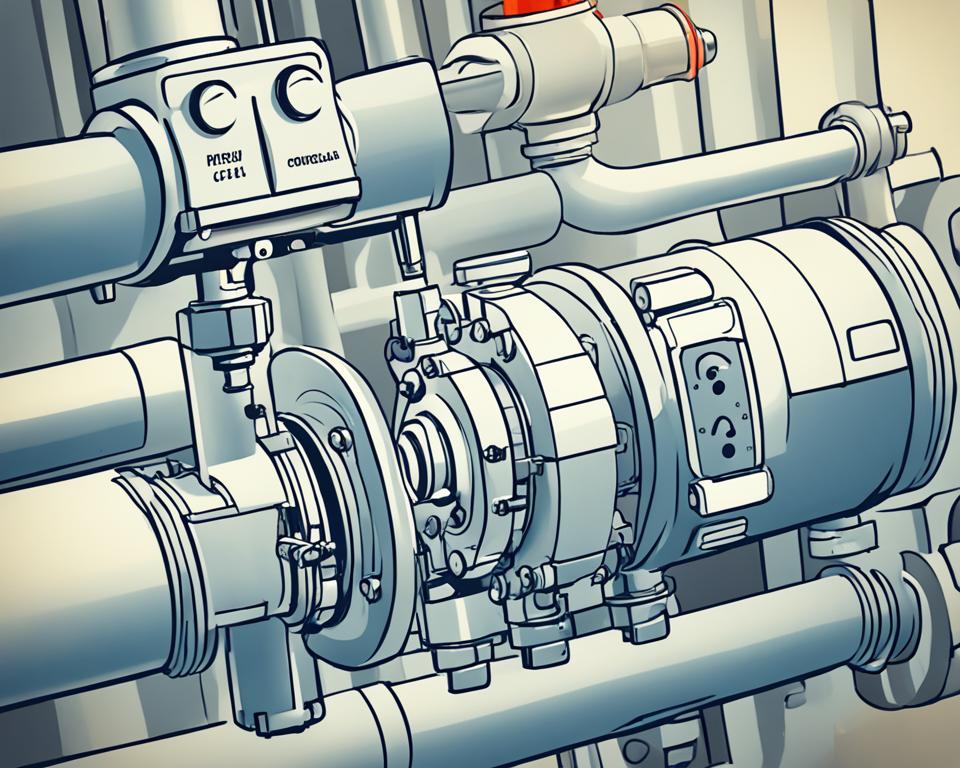

Image:

Troubleshooting Gas Valve Problems in Furnaces

Gas valve problems can occur in furnaces, leading to issues with ignition and heating. Luckily, homeowners can perform basic troubleshooting steps to identify and resolve common gas valve problems before calling a technician.

1. Check the Gas Valve On/Off Switch: Ensure that the gas valve is turned on. Sometimes, it can accidentally get switched off, causing the furnace to stop working.

2. Verify the Position of the Gas Valve Handle/Knob: Make sure the gas valve handle or knob is properly aligned with the “on” position. If it’s misaligned or in the “off” position, adjust it accordingly to allow gas flow to the furnace.

3. Verify the Thermostat Settings: Check the thermostat settings to ensure that it’s set to an appropriate temperature and that the heat mode is turned on. Incorrect thermostat settings can prevent the furnace from receiving the necessary signals to ignite.

4. Understand the Furnace Gas Valve Sequence: Familiarize yourself with the gas valve sequence for your specific furnace model. The gas valve sequence will dictate the specific steps and order of operations required for igniting and controlling the flow of gas in the furnace.

By following these troubleshooting steps, homeowners can effectively resolve common gas valve issues and restore their furnace’s heating capabilities.

Additional Tips:

- Regular maintenance of the furnace, including cleaning and inspection, can help prevent gas valve problems.

- If the troubleshooting steps do not resolve the issue, it is advisable to consult a licensed HVAC technician.

| Gas Valve Problem | Troubleshooting Step |

|---|---|

| No heat from furnace | Check the gas valve on/off switch, position of the gas valve handle/knob, and thermostat settings. |

| Furnace not igniting | Verify the gas valve handle/knob position and the thermostat settings. |

| Intermittent heating | Check for any obstructions in the gas line and ensure that the gas valve is fully open. |

| Strange odors or noises | Inspect the gas valve for any leaks or damage and contact a professional if necessary. |

Conclusion

Dealing with gas control valve and gas valve failures can be a frustrating experience for homeowners. However, there are solutions available that can help resolve these issues and ensure the smooth functioning of gas-powered appliances. By following the troubleshooting steps and maintenance tips provided in this guide, homeowners can effectively address gas control and valve failures.

Regular maintenance is key to preventing gas valve problems. It is important to keep the gas control valve clean and free from debris, as any blockages can disrupt its operation. Additionally, checking the wiring connections and ensuring proper ventilation can help prevent future issues.

In cases where troubleshooting steps have been followed without success, it is advisable to seek professional assistance. Experienced technicians have the expertise to accurately diagnose and resolve complex gas control valve problems. They can provide the necessary repairs or replacements to restore the proper functioning of the gas valve.

Remember, understanding common problems associated with gas control valves and knowing when to seek professional help are vital in maintaining the safety and functionality of gas-powered appliances. By implementing regular maintenance routines and promptly addressing any issues, homeowners can avoid major gas valve failures and ensure the efficient operation of their gas appliances for years to come.

FAQ

What are some common issues with gas control valves?

Common issues with gas control valves include improper installation, unsuitable environmental conditions, and backdrafting. These problems can affect the proper functioning of gas appliances.

What are some installation tips for gas control valves?

It is important to ensure proper ventilation by having a sufficient rise in the vent before the first elbow. If the unit is common vented with a connector rise of less than 3 feet, using a larger vent size is recommended.

How can Honeywell gas control valves be troubleshooted?

The LED indicator on Honeywell gas control valves provides valuable troubleshooting information. Different flash codes indicate specific issues such as pilot not lit, thermopile low voltage, temperature exceeded, sensor failure, or gas control valve failure. Steps can be taken to resolve the problem based on the specific issue indicated.

When should professional assistance be sought for gas control valve issues?

If troubleshooting steps have been followed without success, it is advisable to consult a professional water heater technician. They have the knowledge and expertise to accurately diagnose and address complex problems.

How can gas valve problems in furnaces be troubleshooted?

Before calling a technician, homeowners can perform basic troubleshooting steps such as checking the gas valve on/off switch, the position of the gas valve handle/knob, and the thermostat settings. Understanding the furnace gas valve sequence can also help in troubleshooting.

How can gas control and valve failures be addressed?

Gas control and valve failures can be resolved by following the appropriate troubleshooting steps and regular maintenance. Understanding common issues and seeking professional assistance when needed can help ensure the proper functioning of gas-powered appliances.

![Ray Dalio Quotes [Principles, Life, Investment]](https://tagvault.org/wp-content/uploads/2023/04/Screen-Shot-2023-04-19-at-7.57.49-PM.png)