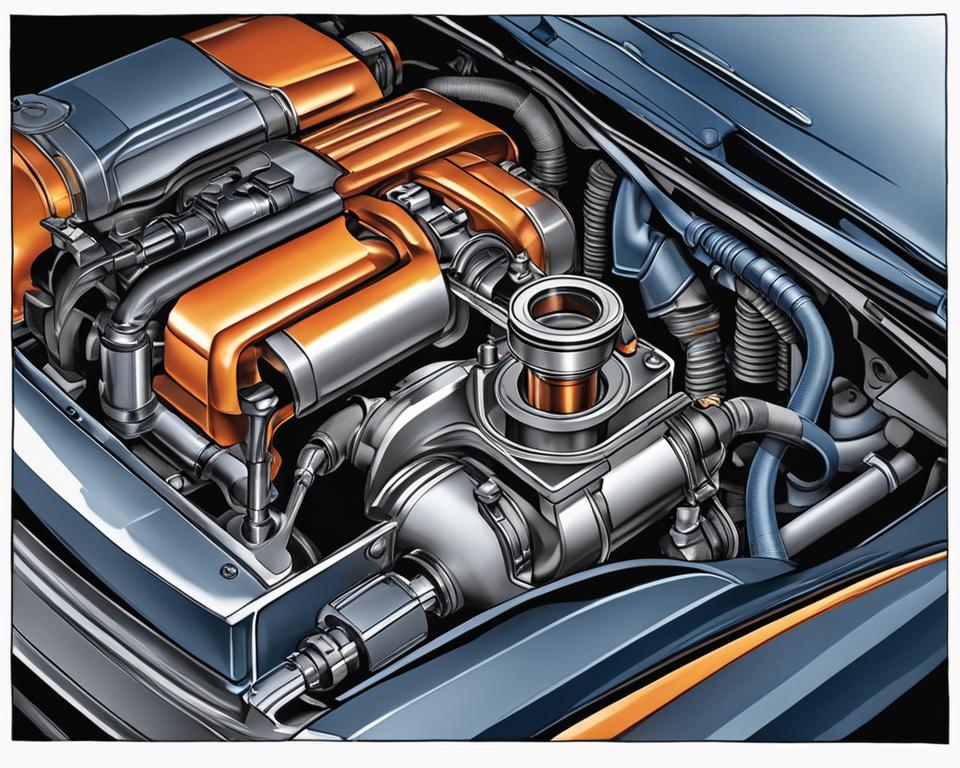

Welcome to our article on fuel injectors, a critical component of the modern automotive fuel injection system. If you’re wondering how a fuel injector works and what its function is, you’ve come to the right place. In this section, we will provide you with an overview of fuel injectors and their role in delivering the correct quantities of air and fuel to a car’s engine.

Key Takeaways:

- Fuel injection systems replace carburetors in modern cars for improved efficiency.

- Injectors, fuel pumps, fuel distributors, and cold-start injectors are key components of a fuel injection system.

- There are different types of injectors, including electronic and mechanical, controlling the flow of fuel.

- Fuel is delivered to the engine through a fuel pump and injected into the inlet port or manifold.

- The design and operation of fuel injectors are crucial for achieving the proper fuel-air mixture.

Components of a Fuel Injection System

A fuel injection system is a complex mechanism consisting of several components that work together to ensure the proper delivery of fuel to the engine. Understanding these components is crucial for mechanics and enthusiasts alike. Let’s take a closer look at the key components of a fuel injection system:

1. Injectors

The injectors are responsible for delivering the fuel into the combustion chambers at the right time. They can be either timed or continuous and are usually electronic or mechanical. The injectors control the flow of fuel and play a critical role in the overall performance of the engine.

2. Inlet Manifold

The inlet manifold is responsible for distributing the air-fuel mixture to each individual cylinder. It ensures that the correct amount of mixture is delivered to each cylinder for optimal combustion and engine performance.

3. Fuel Distributor

The fuel distributor ensures that the fuel is evenly distributed to each injector. It regulates the fuel pressure and flow to maintain a consistent fuel-air ratio throughout the engine.

4. Fuel Pump

The fuel pump is responsible for supplying fuel from the fuel tank to the injectors. It maintains the required fuel pressure to ensure proper atomization and delivery of fuel to the combustion chambers.

5. Fuel Accumulator

The fuel accumulator acts as a storage reservoir for fuel under pressure. It helps maintain a constant fuel pressure for immediate response and consistent fuel delivery, especially during high-demand situations.

6. Cold-Start Injector

The cold-start injector is a specialized injector that delivers an extra burst of fuel during cold starts. It helps facilitate easier ignition and smooth engine operation in low-temperature conditions.

By understanding the function and role of each component, mechanics and enthusiasts can diagnose and troubleshoot fuel injection system issues more effectively. These components work together seamlessly to ensure efficient fuel delivery and optimal engine performance.

Fuel Delivery in a Fuel Injection System

In a fuel injection system, fuel delivery plays a crucial role in ensuring optimal engine performance. The process of fuel injection involves the precise delivery of fuel to the engine bay, where it is then mixed with air before entering the combustion chamber. This process is essential for achieving efficient and controlled combustion, resulting in improved power output and reduced emissions.

Gasoline-powered cars typically use indirect injection, where fuel is injected into the inlet port or manifold before reaching the combustion chamber. This method allows for better control over the fuel-air mixture, resulting in a more efficient combustion process. On the other hand, diesel-fueled cars utilize direct injection, where fuel is injected directly into the cylinder filled with compressed air. This direct injection allows for better atomization of fuel and more precise control over combustion, resulting in increased power and fuel efficiency.

The design of the fuel injector itself plays a crucial role in the fuel delivery process. Fuel injectors are engineered to deliver fuel in precise quantities and at the right pressure. They consist of a nozzle and a valve that work together to control the flow of fuel. The valve opens and closes rapidly, allowing fuel to be injected in short bursts or pulses. This pulsed fuel delivery ensures a consistent and accurate fuel-air mixture for optimal combustion.

The Role of Fuel Pressure

Fuel pressure also plays a significant role in fuel delivery. The fuel pump in the fuel injection system is responsible for maintaining the required pressure to ensure proper fuel delivery. The fuel pressure needs to be carefully regulated to prevent fuel starvation or flooding of the engine. Fuel pressure is typically controlled by a fuel pressure regulator, which adjusts the pressure based on the engine’s demands.

| Fuel Injection System Type | Fuel Delivery Process |

|---|---|

| Indirect Injection | Fuel injected into the inlet port or manifold before reaching the combustion chamber |

| Direct Injection | Fuel injected directly into the cylinder filled with compressed air |

The fuel injector is a critical component in the fuel delivery process, ensuring precise and controlled combustion for optimal engine performance.

In summary, fuel delivery in a fuel injection system involves the precise delivery of fuel to the engine bay, where it is mixed with air before entering the combustion chamber. This process is crucial for achieving efficient combustion and optimizing engine performance. Fuel injectors play a significant role in this process, as they are designed to deliver fuel in precise quantities and at the right pressure. Understanding the fuel delivery process and the role of fuel pressure is essential for maintaining and troubleshooting fuel injection systems.

Diagnosing and Fixing Fuel Injection System Issues

When it comes to the efficiency of a fuel injection system, several issues can arise that require prompt diagnosis and repair. A well-functioning fuel injector is crucial for optimal engine performance and fuel economy. Identifying and resolving fuel injector issues is essential to keep a vehicle running smoothly.

One common problem with fuel injectors is leakage. A leaking injector can cause fuel to seep into the engine or onto hot engine components, leading to potential safety hazards and engine damage. Another symptom of a faulty fuel injector is misfiring, which can result in rough idling, reduced power, and decreased fuel efficiency. Slow acceleration is also often attributed to a malfunctioning fuel injector.

To troubleshoot fuel injector issues, mechanics use specialized diagnostic tools and techniques. They may conduct fuel pressure tests to determine if the injector is delivering fuel at the correct pressure. Additionally, they may inspect the injector for clogs or deposits that could be hindering its operation. In some cases, cleaning the injector or replacing faulty components may be necessary to restore optimal fuel delivery.

Common Symptoms of Fuel Injector Issues:

- Leaking fuel

- Misfiring engine

- Rough idling

- Slow acceleration

- Reduced fuel efficiency

Regular maintenance is crucial to prevent fuel injector issues. Using high-quality fuel and periodically cleaning or replacing the fuel filter can help prolong the life and efficiency of the fuel injection system. However, if problems persist, it is recommended to consult a professional mechanic who can accurately diagnose and repair the fuel injector system.

| Common Fuel Injector Issues | Possible Causes | Recommended Actions |

|---|---|---|

| Leaking fuel | Worn O-rings, faulty seals | Replace O-rings, seals |

| Misfiring engine | Clogged or dirty injectors | Clean or replace injectors |

| Rough idling | Improper fuel delivery | Inspect and adjust fuel pressure |

| Slow acceleration | Insufficient fuel flow | Clean or replace clogged injectors |

Advantages of Fuel Injection Systems

Fuel injection systems offer several advantages over carburetors. These advanced systems provide more precise fuel delivery, resulting in improved engine performance and efficiency. The benefits of fuel injection systems are numerous:

- Enhanced fuel economy: Fuel injection systems optimize fuel delivery, ensuring that the engine receives the right amount of fuel at all times. This precise control helps to maximize fuel efficiency, allowing the car to achieve better mileage.

- Improved engine performance: By delivering fuel directly into the combustion chamber, fuel injection systems ensure a more efficient and consistent combustion process. This leads to increased power, better acceleration, and smoother engine operation.

- Reduced emissions: Fuel injection systems can significantly reduce harmful emissions compared to carburetors. The precise control over fuel delivery helps to achieve a more complete combustion, resulting in lower levels of pollutants released into the atmosphere.

- Reliability and durability: Fuel injection systems are designed to be more reliable and durable than carburetors. They are less prone to issues such as flooding, vapor lock, and fuel leakage, which can negatively impact the performance and reliability of the engine.

- Cold-start capability: Fuel injection systems incorporate a cold-start injector that delivers an extra burst of fuel during cold starts. This helps to ensure a smooth and quick start, even in colder temperatures.

Overall, fuel injection systems offer a range of benefits that make them the preferred choice for modern vehicles. Whether it’s improved fuel economy, enhanced engine performance, or reduced emissions, these systems deliver superior results in terms of efficiency, power, and environmental friendliness.

Different Types of Fuel Injection

There are two main types of fuel injection systems: indirect injection and direct injection. Both types serve the purpose of delivering fuel to the engine, but they differ in their approach.

Indirect injection is commonly used in gasoline-powered cars. In this system, fuel is injected into the inlet port or manifold before entering the combustion chamber. The fuel mixes with the incoming air, creating an appropriate fuel-air mixture for combustion. This type of injection provides good fuel atomization and helps in maintaining a stable combustion process.

Direct injection, on the other hand, is more commonly found in diesel-fueled cars. Here, fuel is injected directly into the cylinder filled with compressed air. This allows for more precise control over the fuel delivery and combustion process. Direct injection systems provide better fuel economy, higher power output, and lower emissions compared to indirect injection systems.

Table: Comparison of Indirect and Direct Fuel Injection Systems

| Indirect Injection | Direct Injection | |

|---|---|---|

| Fuel Delivery | Into the inlet port or manifold | Directly into the cylinder |

| Fuel Mixing | With incoming air | With compressed air in the cylinder |

| Atomization | Good | Excellent |

| Fuel Economy | Lower compared to direct injection | Higher compared to indirect injection |

| Power Output | Lower compared to direct injection | Higher compared to indirect injection |

| Emissions | Higher compared to direct injection | Lower compared to indirect injection |

Each type of fuel injection has its own advantages and is used based on the specific requirements of the engine. Indirect injection is suitable for gasoline engines where a consistent and stable fuel-air mixture is necessary. Direct injection, on the other hand, offers better control and efficiency, making it ideal for diesel engines that require precise fuel delivery and combustion.

By understanding the different types of fuel injection systems, mechanics and enthusiasts can better appreciate the nuances of engine technology and choose the appropriate system for their specific needs.

How Fuel Injection Systems Control Fuel Delivery

Fuel injection systems rely on advanced technology and complex algorithms to control the delivery of fuel to the engine. This ensures optimal performance and efficiency of the vehicle. The fuel injector, fuel injector control, and fuel injector algorithm all play crucial roles in this process.

The fuel injector is the key component responsible for delivering the correct amount of fuel to the engine at the right time. It operates based on signals received from the engine control unit (ECU) and various sensors throughout the vehicle. The ECU calculates the pulse width, which determines how long the fuel injector stays open to deliver fuel. This calculation is based on factors such as engine speed (RPM), load, coolant temperature, and oxygen level.

By accurately controlling the pulse width, the fuel injection system achieves the desired fuel-air mixture for optimal engine performance. The fuel injector control system continuously adjusts and fine-tunes the fuel delivery based on real-time data from the vehicle’s sensors. This allows the engine to run smoothly and efficiently under various driving conditions.

| Control Factors | Importance |

|---|---|

| Engine Speed (RPM) | High importance |

| Load | High importance |

| Coolant Temperature | Medium importance |

| Oxygen Level | Medium importance |

“The fuel injection system’s ability to precisely control the fuel delivery is a major advantage over carburetors. It allows for improved fuel economy, reduced emissions, and better engine performance.”

The Role of Fuel Injector Algorithm

The fuel injector algorithm is the software program that governs the operation of the fuel injection system. It includes lookup tables and calculations that determine the appropriate fuel delivery based on the control factors mentioned earlier. The algorithm takes into account the specific characteristics of the engine and fuel system to optimize performance.

The algorithm also considers various engine modes, such as idle, acceleration, and deceleration, to adjust the fuel delivery accordingly. This ensures that the engine receives the right amount of fuel at all times, maximizing power output and minimizing fuel consumption. The fuel injector algorithm is continuously updated and refined by manufacturers to improve efficiency and meet emission standards.

In conclusion, fuel injection systems rely on advanced technology and algorithms to control fuel delivery. The fuel injector, fuel injector control, and fuel injector algorithm work together to ensure the engine receives the right amount of fuel at the right time. This precise control results in improved engine performance, better fuel economy, and reduced emissions.

Performance Chips and Fuel Injection Systems

Performance chips are a popular choice for automotive enthusiasts looking to enhance the power and performance of their vehicles. These aftermarket modifications offer a way to optimize the fuel injection system and unlock additional horsepower and torque. By replacing the stock chip in the engine control unit (ECU), performance chips can alter the fuel delivery and spark timing to provide more aggressive settings.

One of the primary advantages of performance chips is their ability to fine-tune the fuel injection system for maximum power output. With modified lookup tables and algorithms, these chips optimize the air-fuel mixture and ignition timing, resulting in improved engine performance. This can translate into faster acceleration, increased top speed, and enhanced overall drivability of the vehicle.

It’s important to note that performance chips are designed with a focus on power gains rather than meeting emissions or fuel economy requirements. While they can provide significant performance improvements, they may not be suitable for all applications. It’s crucial to thoroughly research and carefully select the right performance chip for your specific vehicle and goals.

The Benefits of Performance Chips

• Increased horsepower and torque: Performance chips optimize fuel delivery and ignition timing, resulting in noticeable power gains.

• Enhanced throttle response: With a more aggressive fuel injection system, performance chips offer improved acceleration and throttle response.

• Better fuel efficiency: Some performance chips can optimize fuel economy by adjusting the air-fuel mixture for more efficient combustion.

• Easy installation: In many cases, performance chips can be easily installed without the need for extensive modifications or professional expertise.

| Performance Chip | Features | Compatibility |

|---|---|---|

| Brand A | Advanced fuel mapping, adjustable settings, real-time data display | Most makes and models |

| Brand B | Customizable performance settings, Bluetooth connectivity, extensive vehicle support | Wide range of vehicles, including trucks and SUVs |

| Brand C | Plug-and-play installation, preloaded performance maps, user-friendly interface | Popular car brands and models |

“Installing a performance chip can transform your driving experience by unlocking the full potential of your vehicle’s fuel injection system.” – Automotive Enthusiast

Before installing a performance chip, it’s essential to research and choose a reputable brand that offers compatibility with your specific vehicle. Additionally, it’s always a good idea to consult with a knowledgeable mechanic or automotive expert who can provide guidance and ensure the installation is done correctly. With the right performance chip and proper installation, you can take your vehicle’s performance to the next level.

Conclusion

In conclusion, fuel injection systems are vital components that ensure the proper functioning of a car’s engine. By delivering precise amounts of fuel to the combustion chambers, fuel injectors contribute to improved engine performance, fuel efficiency, and reduced emissions. Whether it’s the electronic or mechanical type, the fuel injector plays a crucial role in controlling the flow of fuel.

Mechanics and enthusiasts should be aware of the various components that make up a fuel injection system, including injectors, fuel pumps, distributors, and cold-start injectors. Understanding how these components work together is essential for troubleshooting and maintaining optimal operation.

In summary, fuel injection systems offer several advantages over carburetors. They provide more precise fuel delivery, resulting in better engine performance and efficiency. Additionally, fuel injectors allow for better control over the fuel-air mixture, leading to smoother engine operation and increased power.

Final thoughts on fuel injectors: Regular maintenance and occasional troubleshooting are necessary to ensure the optimal operation of fuel injection systems. With their complex nature, fuel injectors require attention and care to prevent issues such as leaking or misfiring. By understanding how fuel injectors work and their importance in the overall functionality of a car, mechanics and enthusiasts can ensure the longevity and performance of their vehicles.

FAQ

How does a fuel injector work?

A fuel injector is responsible for delivering the correct quantities of air and fuel to a car’s engine. It does this by injecting fuel into the combustion chambers at the right time.

What are the components of a fuel injection system?

A fuel injection system consists of components such as injectors, an inlet manifold, a fuel distributor, a fuel pump, a fuel accumulator, and a cold-start injector.

How does fuel delivery work in a fuel injection system?

Fuel is delivered to the engine bay via a fuel pump and then injected into the inlet port or manifold. The fuel and air mix before entering the combustion chamber.

How can fuel injection system issues be diagnosed and fixed?

When a fuel injector is not functioning properly, it can lead to issues such as leaking, misfiring, rough idling, and slow acceleration. Troubleshooting and repairing fuel injectors may require cleaning or replacement.

What are the advantages of fuel injection systems?

Fuel injection systems provide more precise fuel delivery, improved engine performance, reduced emissions, better fuel economy, and better control over the fuel-air mixture.

What are the different types of fuel injection?

The different types of fuel injection systems include indirect injection, commonly used in gasoline-powered cars, and direct injection, more common in diesel-fueled cars.

How do fuel injection systems control fuel delivery?

Fuel injection systems rely on complex algorithms and lookup tables to determine the pulse width for fuel delivery. The engine control unit (ECU) calculates the pulse width based on factors such as engine speed, load, coolant temperature, and oxygen level.

What are performance chips and their relation to fuel injection systems?

Performance chips are aftermarket modifications that can be installed in the engine control unit (ECU) to enhance engine power. They contain modified lookup tables for more aggressive fuel delivery and spark timing.

How important are fuel injection systems in a car’s engine?

Fuel injection systems play a crucial role in providing precise fuel delivery, improved engine performance, and better fuel economy. Understanding how they work and their various components is essential for mechanics and enthusiasts.