Generators are fascinating devices that play a crucial role in providing power when we need it the most. Whether during a power outage or in remote areas, generators ensure the continuous supply of electricity by converting mechanical energy into electrical energy. But how exactly do they work? Let’s delve into the mechanisms and components that make generators function.

Key Takeaways:

- Generators convert mechanical energy into electrical energy.

- They do not create electrical energy, but rather use mechanical energy to move electric charges through an external circuit.

- The main components of a generator include the engine, alternator, fuel system, voltage regulator, cooling and exhaust systems, lubrication system, battery charger, control panel, and main assembly/frame.

- Understanding generator operation principles is essential for safe and efficient use.

- Generators ensure the continuous supply of electricity for various applications.

The Function of an Engine in a Generator

The engine plays a crucial role in a generator as it provides the necessary mechanical energy input. Generators can be powered by different types of engines depending on the fuel used. Common fuels for generators include diesel, gasoline, propane, or natural gas. The type of engine used in a generator can impact its overall performance and efficiency.

One type of engine commonly used in generators is the overhead valve (OHV) engine. OHV engines offer several advantages, including a compact design, simplicity, durability, user-friendliness, low noise levels, and low emission levels. The OHV design allows for better combustion efficiency, resulting in improved fuel consumption and reduced environmental impact.

Another important component in the engine is the presence of a cast iron sleeve (CIS) in the engine cylinder. The CIS enhances engine durability by providing an extra layer of protection against wear and tear. This feature ensures that the engine can withstand continuous usage and perform reliably over an extended period.

“The engine is like the heart of the generator, providing the necessary power to generate electricity. The type of engine and its design features significantly impact the performance, fuel efficiency, and overall reliability of the generator.”

Types of Engines Used in Generators

| Engine Type | Fuel Used | Advantages |

|---|---|---|

| Overhead Valve (OHV) Engine | Diesel, gasoline, propane, natural gas | – Compact design |

| – Simplicity | ||

| – Durability | ||

| – User-friendliness | ||

| – Low noise levels | ||

| – Low emission levels |

The engine of a generator is a vital component that determines its performance and reliability. By understanding the different types of engines and their features, users can make informed decisions when selecting a generator that suits their specific needs.

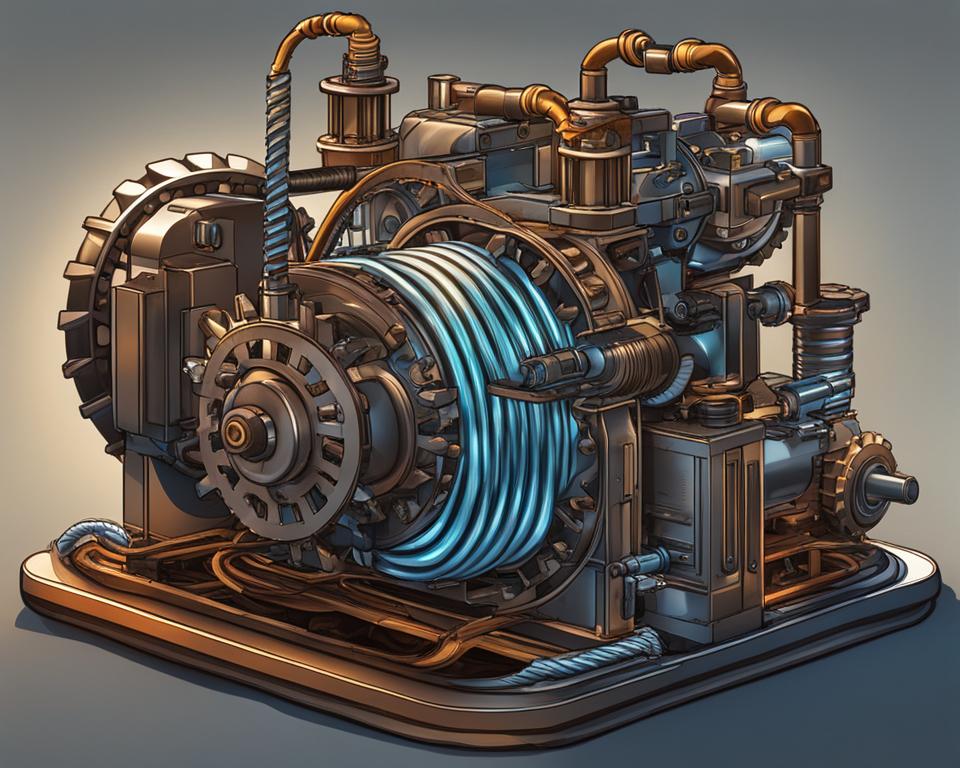

The Role of an Alternator in a Generator

An alternator, also known as the genhead, is a crucial component of a generator that is responsible for producing the electrical output. It works hand in hand with the engine to generate the power needed to run various appliances and devices.

The alternator consists of two main parts: the stator and the rotor or armature. The stator contains electrical conductors wound in coils over an iron core. These coils are strategically positioned to create a magnetic field that interacts with the rotor.

The rotor, on the other hand, generates a rotating magnetic field by using magnets or an exciter, depending on the type of alternator. This rotating magnetic field induces a voltage difference in the stator windings, which in turn produces the alternating current (AC) output of the generator.

Unlike a motor that converts electrical energy into mechanical energy, the alternator uses the mechanical energy from the engine to generate electrical energy. This process is made possible by the principle of electromagnetic induction, which was discovered by Michael Faraday in the early 19th century.

Types of Alternators

Alternators can come in various designs to suit different generator applications. One common type is the brushless alternator, which is used in larger generators. As the name suggests, brushless alternators eliminate the need for carbon brushes and commutators, resulting in a more reliable and low-maintenance design.

Another type of alternator utilizes permanent magnets instead of exciter windings or electromagnets. These permanent magnet alternators are known for their efficiency and compact size, making them suitable for portable and smaller generators.

Overall, the alternator plays a vital role in the functioning of a generator, converting mechanical energy into electrical energy through the principles of electromagnetic induction. Understanding its components and operation is essential for properly utilizing and maintaining a generator.

The Fuel System in a Generator

A fuel system is a crucial component of a generator, ensuring the efficient and reliable delivery of fuel to power the engine. Let’s explore the key elements of a generator’s fuel system.

Fuel Tank

The fuel tank is where the generator stores the fuel needed for operation. It is designed to hold a sufficient amount of fuel to keep the generator running for an extended period of time. The capacity of the fuel tank depends on the size and intended use of the generator. Larger generators typically have larger fuel tanks to accommodate longer run times.

Pipe Connection and Ventilation

The fuel tank is connected to the engine through a pipe connection, which allows the fuel to flow from the tank to the engine. Proper pipe connections ensure the seamless transfer of fuel and prevent leaks. Additionally, generators require proper ventilation to maintain optimal fuel efficiency and prevent the buildup of harmful gases. A ventilation pipe is essential for the removal of excess heat and fumes.

Fuel Pump

The fuel pump plays a vital role in the fuel system by transferring fuel from the main storage tank to a smaller day tank or directly to the engine. It ensures a consistent and controlled flow of fuel, optimizing engine performance. The type of fuel pump used in a generator can vary depending on the generator’s size and design.

Fuel Water Separator and Fuel Injector

To protect the components of the generator and ensure the smooth operation of the engine, a fuel water separator is incorporated into the fuel system. This component filters out water and foreign matter from the fuel, preventing potential damage. The fuel injector atomizes the liquid fuel and sprays it into the combustion chamber of the engine, facilitating efficient and controlled fuel combustion.

Table: Comparison of Common Fuel System Components

| Fuel System Component | Function | Key Features |

|---|---|---|

| Fuel Tank | Stores fuel for generator operation | Varies in size depending on generator capacity |

| Pipe Connection | Transfers fuel from tank to engine | Ensures leak-free and efficient fuel flow |

| Ventilation Pipe | Removes excess heat and fumes | Prevents fuel system overheating |

| Fuel Pump | Transfers fuel from tank to engine | Ensures consistent and controlled fuel flow |

| Fuel Water Separator | Filters out water and foreign matter from fuel | Protects generator components from potential damage |

| Fuel Injector | Atomizes and sprays fuel into the combustion chamber | Facilitates efficient and controlled fuel combustion |

Understanding Voltage Regulation in a Generator

The voltage regulator is a critical component in a generator that plays a key role in maintaining a stable electrical supply. It ensures that the output voltage remains within the desired range, regardless of variations in the load or speed of the generator.

One of the main functions of the voltage regulator is to convert the AC voltage produced by the generator’s alternator into DC current. This AC to DC conversion is achieved using rectifiers, which are electronic devices that allow the current to flow in only one direction.

In a generator, the voltage regulator uses the DC current to energize the exciter windings. These windings generate a small AC current, which is then converted back to DC current by rotating rectifiers. This DC current is then fed to the rotor or armature, inducing a larger AC voltage in the stator windings and producing the generator’s electrical output.

| AC to DC Conversion | Exciter Windings | Rotating Rectifiers | DC to AC Conversion |

|---|---|---|---|

| The voltage regulator converts AC voltage to DC current. | The DC current is used to energize the exciter windings. | The exciter windings produce a small AC current. | The AC current is converted back to DC current by rotating rectifiers. |

By regulating the voltage output, the voltage regulator ensures that the electrical devices connected to the generator receive a consistent and reliable power supply. This is particularly important for sensitive equipment that may be susceptible to voltage fluctuations.

The voltage regulator also helps protect the generator from excessive voltage, which can damage its components. It monitors the output voltage and adjusts the excitation current to maintain the desired voltage level.

In summary, the voltage regulator in a generator is responsible for converting AC to DC, energizing the exciter windings, converting AC back to DC, and maintaining a stable output voltage. It is a vital component that ensures the generator delivers consistent and reliable electrical power.

Cooling and Exhaust Systems in a Generator

Generators require efficient cooling and exhaust systems to maintain optimal performance and prevent overheating. These systems play a crucial role in dissipating the heat generated during continuous usage, ensuring the safe and reliable operation of the generator.

Generator Cooling System

The cooling system in a generator helps regulate the temperature and prevent the internal components from overheating. Several cooling methods are used in generators depending on their size and application.

- Raw/Fresh Water Cooling: Large generators often employ raw or fresh water cooling systems. In this method, water is used to absorb heat from the generator and is circulated through the engine and generator to dissipate the heat.

- Hydrogen Cooling: For certain types of generators, such as those used in power plants, hydrogen cooling is employed. Hydrogen has excellent thermal conductivity, enabling efficient heat dissipation.

- Ventilation: Adequate ventilation is essential to prevent heat buildup in the generator. The generator housing should have proper air vents and fans to ensure a continuous flow of air, removing excess heat from the system.

Exhaust Systems and Muffler

The exhaust system of a generator is responsible for removing combustion byproducts and directing them away from the generator and surrounding areas. It ensures the safe discharge of exhaust gases, including carbon monoxide, which is a toxic gas.

A well-designed exhaust system consists of a muffler that reduces noise levels and a pipe that directs the exhaust gases away from the generator and the building. The muffler is designed to dampen the sound produced by the generator, making it quieter during operation.

The proper installation and maintenance of the cooling and exhaust systems are essential for the safe and efficient operation of generators. Regular inspection and cleaning of the cooling system components, including the radiator and water pump, help ensure optimal performance and prolong the generator’s lifespan.

Next, we will discuss the electrical requirements for operating a generator, including the importance of sizing the generator correctly and using a transfer switch for safe operation.

Electrical Requirements for Operating a Generator

Operating a generator requires careful consideration of various electrical requirements to ensure safe and efficient operation. From sizing the generator to selecting the right accessories, each aspect plays a vital role in maximizing the generator’s performance and protecting your electrical devices.

Sizing the Generator

One of the key electrical requirements for operating a generator is selecting the appropriate size. Sizing the generator correctly is crucial to meet the electrical loads and prevent voltage issues. The power capacity of a generator is typically measured in watts or kilowatts (kW), and it should be matched to the combined wattage of the appliances and devices you plan to power. By choosing a generator with the right capacity, you can ensure that it can handle the load without overloading or damaging its components.

Transfer Switch

When connecting a generator to your home’s electrical system, it’s essential to use a transfer switch. A transfer switch allows for safe and easy switching between utility power and generator power. It ensures that the generator’s electricity is isolated from the main power grid, preventing any potential accidents or damage to utility workers. A transfer switch also enables you to select which circuits or appliances you want to power during a power outage, providing flexibility and control over your backup power supply.

GFCI Compatibility and Heavy-Duty Cords

For added safety, it’s important to consider the compatibility of Ground Fault Circuit Interrupter (GFCI) outlets with your generator. GFCI outlets provide enhanced protection against electrical shocks and are highly recommended for outdoor use or areas prone to moisture. Some generators come equipped with built-in GFCI outlets, while others may require GFCI adapters or extension cords.

Speaking of cords, using heavy-duty cords designed for generator use is essential. These cords are typically rated for higher wattage and have thicker insulation to handle the power output of the generator. They minimize the risk of overheating or voltage drops, ensuring a stable and safe connection between the generator and your devices.

Ground Rod

Proper grounding is crucial for electrical safety when operating a generator. A ground rod is an important component of the grounding system, providing a safe path for electrical faults to dissipate into the ground. It helps protect you, your electrical devices, and the generator from electrical surges or faults. The ground rod should be installed according to local electrical codes and guidelines to ensure effective grounding.

To summarize, understanding and meeting the electrical requirements for operating a generator is essential for a safe and reliable power supply. Consider sizing the generator correctly, using a transfer switch, ensuring GFCI compatibility, utilizing heavy-duty cords, and implementing proper grounding measures. By following these guidelines, you can maximize the performance of your generator and ensure the safety of your electrical system.

Carbon Monoxide Safety with Generators

When operating a generator, it is crucial to prioritize carbon monoxide safety to protect yourself and others from this odorless and potentially deadly gas. Here are some important guidelines to follow:

- Operate in well-ventilated areas: Generators should never be used indoors or in enclosed spaces. Always set up the generator in a well-ventilated area, such as outside in open air or in a fully open garage.

- Direct the exhaust away: Position the generator in a way that ensures the exhaust is directed away from the house or any occupied areas. The exhaust should be able to dissipate safely into open air, reducing the risk of carbon monoxide buildup.

- Install carbon monoxide detectors: It is highly recommended to install carbon monoxide detectors in your home, especially near bedrooms and living areas. These detectors will alert you if carbon monoxide levels become unsafe, allowing you to take immediate action.

Remember, carbon monoxide is a silent killer, and the consequences can be fatal. By following these safety precautions, you can enjoy the benefits of using a generator without compromising your well-being and that of your loved ones.

Carbon Monoxide Poisoning Symptoms

It is essential to be aware of the symptoms of carbon monoxide poisoning, as early detection can save lives. The symptoms may include:

- Headaches

- Dizziness

- Nausea

- Confusion

- Shortness of breath

- Loss of consciousness

Remember, if you or someone else experiences these symptoms and suspect carbon monoxide poisoning, immediately move to a well-ventilated area and seek medical attention.

| CO Level (ppm) | Symptoms |

|---|---|

| 9 | None |

| 35 | Headache, dizziness, and fatigue within 6-8 hours |

| 100 | Nausea, vomiting, headaches, and dizziness within 2-3 hours |

| 200 | Confusion, severe headaches, dizziness, and nausea within 1-2 hours |

| 400 | Loss of consciousness, life-threatening symptoms within 1-2 hours |

Fuel Quality and Safety for Generators

Ensuring proper fuel quality and safety measures is crucial for the reliable and efficient operation of generators. When refueling your generator, it is important to follow precautions to prevent accidents and maintain the integrity of the fuel supply.

Fuel Refueling Precautions

- Always turn off the generator and allow it to cool down before refueling to avoid the risk of fire or burns.

- Keep open flames, cigarettes, and sparks away from the refueling area to prevent ignition of fuel vapors.

- Use a clean and approved fuel container specifically designated for storing and transporting fuel.

- Avoid overfilling the fuel tank to minimize the possibility of fuel spillage.

Fuel Storage

Proper fuel storage is essential to maintain fuel quality and prevent contamination:

- Store fuel in a well-ventilated, designated area away from the generator and potential sources of ignition.

- Avoid storing fuel near flammable materials, electrical appliances, or in direct sunlight.

- Ensure the fuel storage container is tightly sealed to prevent evaporation and water absorption.

Fuel Stabilizer

Using a fuel stabilizer can help slow down fuel degradation and extend its shelf life. Fuel stabilizers are additives that inhibit the formation of gum and varnish, reduce corrosion, and help maintain optimal fuel quality over time. Follow the manufacturer’s instructions for the appropriate fuel stabilizer dosage and mixing procedure.

Refueling Hot Generators

Refueling should only be done when the generator has cooled down. Refueling a hot generator can pose serious safety risks, including the potential for fuel ignition or explosions. Allow the generator to cool for at least 15-20 minutes before refueling to ensure a safe and controlled refueling process.

| Fuel Quality Tips | Fuel Safety Tips |

|---|---|

| Use fresh, clean fuel without contaminants or water. | Turn off the generator and allow it to cool before refueling. |

| Store fuel in a well-ventilated area away from ignition sources. | Avoid open flames, cigarettes, and sparks near the refueling area. |

| Add fuel stabilizer to prevent fuel degradation. | Use a designated fuel container for safe storage and transport. |

| Follow the manufacturer’s recommendations for fuel type and octane rating. | Do not overfill the fuel tank to prevent spillage. |

Weather Safety Precautions for Generators

When using a generator, it’s important to take weather safety precautions to ensure its proper functioning and longevity. Here are some essential tips to keep in mind:

Generator Cover

To protect your generator from the elements, consider using a generator cover. This cover will shield the generator from rain, snow, and other weather conditions, preventing damage and extending its lifespan. Make sure the cover is made of durable and waterproof material to provide maximum protection.

Air Space

When setting up your generator, ensure there is sufficient air space around it. Generators require proper ventilation to prevent overheating. Adequate air circulation will help dissipate heat and maintain the generator’s optimal temperature. Avoid placing the generator in enclosed spaces or close to walls or other objects that may impede airflow.

Wind Direction

When positioning your generator, consider the direction of the wind. It’s important to orient the generator in a way that the exhaust is directed away from occupied spaces and areas where people congregate. This will help prevent carbon monoxide buildup and ensure the safety of those in the vicinity.

Secure Generator

To protect your generator from theft or tampering, it’s crucial to secure it properly. Consider using chains or locks to secure the generator in place. Additionally, if your generator is installed outdoors, make sure it is placed in a location that is not easily accessible to unauthorized individuals. Taking these security measures will help safeguard your investment and ensure uninterrupted power supply when you need it most.

By following these weather safety precautions, you can ensure the reliable and safe operation of your generator, regardless of the weather conditions. Keep in mind that proper maintenance and regular inspections are also essential to maximize the performance and lifespan of your generator.

Other Types of Electricity Generators

While turbine-driven generators are commonly used for electricity generation, there are several other types that harness different sources of energy. These alternative generators are gaining popularity due to their environmental benefits and versatility. Let’s explore some of the different types:

Solar Photovoltaic

Solar photovoltaic (PV) systems are an increasingly popular choice for generating electricity. These systems use solar panels to convert sunlight directly into electricity through the photovoltaic effect. The panels consist of multiple solar cells made of semiconducting materials, typically silicon. When sunlight hits the cells, it generates an electric current. Solar PV systems are reliable, eco-friendly, and have the potential to significantly reduce reliance on traditional power sources.

Internal-Combustion Engines

Internal-combustion engines, such as diesel engines, are widely used for electricity generation. These engines burn fuel, such as diesel or natural gas, inside a combustion chamber to produce mechanical energy. This mechanical energy is then converted into electrical energy using a generator. Internal-combustion generators are commonly used in portable and backup power applications due to their compact size and high power output.

Fuel Cells

Fuel cells are devices that generate electricity through a chemical reaction between hydrogen and oxygen. They operate without combustion, making them highly efficient and environmentally friendly. Fuel cells are commonly used in stationary and transportation applications. They offer advantages such as low emissions, quiet operation, and the ability to produce electricity continuously as long as a fuel source is supplied. Fuel cell technology is still evolving, and there are various types of fuel cells available, including proton-exchange membrane (PEM) fuel cells and solid oxide fuel cells (SOFC).

Energy Storage Systems

Energy storage systems play a crucial role in electricity generation by storing excess energy and releasing it when needed. These systems include technologies such as hydro-pumped storage and batteries. Hydro-pumped storage involves using excess electricity to pump water to a higher elevation, which can later be released to generate electricity during peak demand periods. Battery storage systems, on the other hand, store electricity in chemical form and can be used for short-term or long-term energy storage. Energy storage systems are crucial for balancing the intermittent nature of renewable energy sources and ensuring a stable supply of electricity.

| Generator Type | Main Source of Energy | Advantages | Applications |

|---|---|---|---|

| Solar Photovoltaic | Sunlight | – Renewable and environmentally friendly – Can be installed on rooftops or in large solar farms – Low maintenance requirements |

– Residential and commercial buildings – Utility-scale solar farms |

| Internal-Combustion Engines | Fossil fuels (e.g., diesel, natural gas) | – Compact size and high power output – Quick startup and shutdown – Availability of various fuel options |

– Backup power for homes and businesses – Portable power for construction or outdoor events |

| Fuel Cells | Chemical reaction between hydrogen and oxygen | – High energy efficiency – Low emissions – Relatively quiet operation |

– Stationary power generation for homes, offices, and data centers – Transportation applications (e.g., fuel cell vehicles) |

| Energy Storage Systems | Excess electricity from various sources | – Smoothing out the intermittent nature of renewable energy – Backup power during outages – Dynamic load management |

– Power grid stabilization – Renewable energy integration – Residential and commercial applications |

These alternative generators provide diverse options for meeting electricity needs while reducing environmental impact. As advancements continue to be made in energy technologies, we can expect further improvements in efficiency, affordability, and integration with existing power systems.

Conclusion

Generators are incredible devices that provide a reliable source of electrical energy by converting mechanical energy. Their operation is based on the principles of electromagnetic induction, discovered by Michael Faraday. By understanding the components and mechanisms involved, we can appreciate the importance of generators in various applications.

Whether it’s powering our homes during outages or enabling remote areas to have electricity, generators play a vital role in ensuring a continuous power supply. The main components, including the engine, alternator, fuel system, and voltage regulator, work together to convert mechanical energy into electrical energy.

Having knowledge about how generators work allows for safe and efficient operation. From selecting the right fuel to ensuring proper ventilation and voltage regulation, understanding generator functionality is essential.

FAQ

How does a generator work?

A generator converts mechanical energy from an external source into electrical energy by moving electric charges through an external circuit.

What are the main components of a generator?

The main components of a generator include the engine, alternator, fuel system, voltage regulator, cooling and exhaust systems, lubrication system, battery charger, control panel, and main assembly/frame.

What is the role of an engine in a generator?

The engine is responsible for providing the mechanical energy input to the generator.

What types of fuel can be used in a generator?

Generators can use diesel, gasoline, propane, or natural gas as fuel.

What is an alternator and what is its role in a generator?

The alternator, also known as the genhead, produces the electrical output of the generator by producing a rotating magnetic field that induces a voltage difference in the stator windings.

How does a voltage regulator work in a generator?

The voltage regulator regulates the output voltage of the generator by converting AC voltage to DC current and energizing the exciter windings to produce the desired output.

What safety precautions should be taken with a generator?

Generators should never be operated in enclosed or poorly ventilated areas, and the exhaust should be directed away from the house to prevent carbon monoxide buildup. Proper fuel quality and storage, as well as weather safety precautions, should also be observed.

What are the different types of electricity generators?

Besides traditional turbine-driven generators, there are also solar photovoltaic systems, internal-combustion engines, fuel cells, Stirling engines, thermoelectric generators, and energy storage systems, such as hydro-pumped storage or batteries.

Why are generators important?

Generators play a crucial role in providing backup power during outages or in remote areas, ensuring a continuous supply of electricity for various applications.