Dealing with a broken screw can be frustrating, but fear not! There are effective methods to remove it and save the day. Whether you’re dealing with a stripped head, a rusted screw, or one that’s stuck, we’ve got you covered. In this guide, we’ll walk you through various techniques to get that broken screw out with ease.

So, if you’re ready to learn how to conquer those stubborn broken screws, keep reading!

Key Takeaways:

- Removing a broken screw can be challenging, but with the right techniques, it’s possible.

- Methods like using a screw extractor, drilling a hole, or using pliers can help you extract the broken screw.

- Prevent stripped screw heads by using the correct screwdriver and applying even pressure while turning.

- For rusted or seized screws, try applying lubricants or using shock & awe methods to break the bonds.

- If all else fails, consider using alternative methods like gluing tools or destroying the screw with demolition tools.

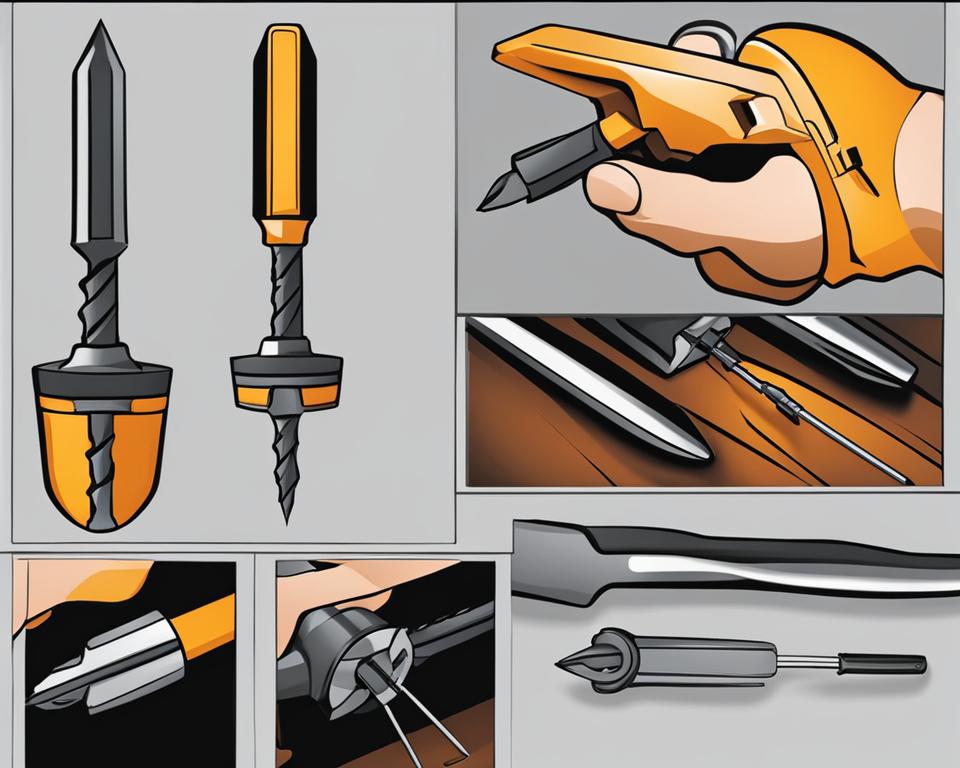

Using a Screw Extractor

One effective method for removing a broken screw is to use a screw extractor. A screw extractor is a specialized tool designed to grip onto the broken screw and provide leverage for its removal. You can easily find screw extractors at most home improvement stores.

To use a screw extractor, start by drilling a small hole in the center of the broken screw using a drill bit that is slightly smaller than the size of the extractor. This hole will serve as a guide for the extractor. Then, insert the screw extractor into the hole and firmly tap it with a hammer to ensure a secure fit.

Next, use a wrench or pliers to turn the screw extractor counterclockwise. The extractor’s threads will catch onto the broken screw, allowing you to remove it from the material. Apply steady pressure as you turn the extractor to avoid stripping the surrounding material.

Benefits of Using a Screw Extractor

- Specifically designed for removing broken screws

- Provides leverage to ease screw extraction

- Available at most home improvement stores

- Can be used on various types of screws

Using a screw extractor is a reliable and efficient method for removing broken screws. Its specialized design and ease of use make it a valuable tool for DIY enthusiasts and professionals alike. With a screw extractor in your toolbox, you’ll be prepared to tackle any broken screw removal task that comes your way.

| Screw Extractor Size | Drill Bit Size | Material Compatibility |

|---|---|---|

| #1 | 5/64″ | Softwood, Plastic |

| #2 | 7/64″ | Softwood, Hardwood, Plastic |

| #3 | 5/32″ | Softwood, Hardwood, Plastic, Metal |

| #4 | 1/4″ | Softwood, Hardwood, Plastic, Metal |

How to Choose the Right Screw Extractor Size

When selecting a screw extractor, it is important to choose the right size for the broken screw. The size of the screw extractor corresponds to the size of the drill bit that is required to create a pilot hole in the broken screw. Refer to the table above to identify the appropriate screw extractor size based on the type of material and screw size.

Drilling a Hole in the Screw

When dealing with a broken screw that has a stripped head or can’t be unscrewed by other means, drilling a hole in the screw can be an effective solution. This method allows you to create a new point of leverage to remove the screw.

To drill a hole in the screw, start by selecting a small drill bit that is slightly smaller than the diameter of the screw. Place the drill bit in the center of the screw head and apply gentle pressure as you begin drilling. It’s essential to go slowly to prevent damaging the surrounding material or pushing the screw deeper into the surface.

Once the hole is drilled, you can continue enlarging it gradually using larger drill bits until the hole is large enough to accommodate a screw extractor or a screwdriver. With the hole in place, you’ll have a new grip point that allows you to apply torque and unscrew the broken screw successfully.

| Advantages | Disadvantages |

|---|---|

| – Creates a new point of leverage | – Requires a drill and drill bits |

| – Works for stripped screw heads | – Can damage the surrounding material if not done carefully |

“Drilling a hole in the screw head can be an effective way to remove a broken screw with a stripped or damaged head. Take care to drill slowly and precisely to avoid causing further damage to the material.”

Using Pliers to Grip the Screw

To remove a broken or stuck screw when the head is completely stripped or absent, using pliers can be an effective method. By gripping the screw shank with pliers as close to the material as possible, you can apply firm pressure and turn the pliers counterclockwise to release the screw from the material.

This method is particularly useful for screws that cannot be accessed from the top or for screws that are flush with the surface, making it difficult to use other extraction techniques. Additionally, it does not require any specialized tools and can be easily done with a pair of pliers that you may already have in your toolbox.

When using pliers to remove a broken screw, it’s important to choose pliers with a strong grip and serrated jaws to provide the necessary traction. If the screw is stubborn and does not release easily, you can try applying some penetrating oil or lubricant to help loosen it before attempting to twist it out with the pliers.

“Using pliers to grip the screw shank is a practical method for removing broken or stuck screws that cannot be accessed from the top or have completely stripped heads.”

Example:

| Pliers Types | Usage |

|---|---|

| Locking Pliers | Provide a strong grip and adjustable jaws for securing the screw shank. |

| Long-Nose Pliers | Allow for better access to screws in narrow or confined spaces. |

| Needle-Nose Pliers | Offer precise control when gripping small or delicate screws. |

Table: Common Types of Pliers for Removing Broken or Stuck Screws.

Preventing Stripped Screw Heads

Preventing stripped screw heads is important to avoid frustration and save time during DIY projects. By following a few simple tips, you can minimize the risk of damaging screw heads and ensure smoother screw removal in the future.

Proper Screwdriver Alignment

One key factor in preventing stripped screw heads is aligning the screwdriver properly with the screw. When inserting the screwdriver into the head, make sure it fits snugly and matches the screw’s drive type, such as Phillips or flathead. Applying even pressure while turning the screwdriver will help prevent slipping and stripping of the screw head.

Avoiding Power Drills

While power drills can be convenient for driving screws quickly, they can also increase the risk of stripping screw heads. The high speed and torque of power drills can cause the screwdriver bit to slip and strip the head. To prevent this, consider using a manual screwdriver for more control and accuracy when driving screws.

Using the Right Screwdriver Type

Using the appropriate screwdriver type for different screw heads is essential for preventing damage. For screws with different shapes, such as star-shaped screws or hex screws, make sure to use the correct screwdriver type. Using the wrong type can lead to slipping and stripping of the screw head, making it difficult to remove the screw later on.

By following these tips, you can greatly reduce the chances of encountering stripped screw heads. Taking the time to use the correct screwdriver, avoiding power drills when possible, and using the appropriate screwdriver type for different screws will help maintain the integrity of screw heads and make future screw removal much easier.

Removing Rusted or Seized Screws

Dealing with rusted or seized screws can be a frustrating task. These screws can become stubbornly stuck due to rust or corrosion, making them difficult to remove using traditional methods. However, there are techniques you can use to successfully remove these troublesome screws.

One effective method is to apply a lubricant or penetrating oil to the rusted screw. This helps to loosen the rust and corrosion, making it easier to turn and remove the screw. Allow the lubricant to sit for a few minutes or even overnight before attempting to remove the screw. This gives the lubricant enough time to penetrate and break up the bonds between the screw and the surrounding material.

Another technique, known as the shock & awe method, involves tapping the rusted screw with a hammer. The force from the hammer can help break the bonds and loosen the screw. Be careful not to apply too much force, as this can damage the surrounding material. Start with gentle taps and gradually increase the force if needed.

If all else fails, you may need to resort to more drastic measures. Drilling out the screw or using demolition tools can be effective in extreme cases. However, these methods should only be used as a last resort, as they can cause damage to the material or surrounding area. Proceed with caution and consider seeking professional help if you are unsure.

Tips for Removing Rusted or Seized Screws:

- Apply a lubricant or penetrating oil to loosen the rust.

- Allow the lubricant to sit for a few minutes or overnight.

- Tap the screw with a hammer to break the bonds.

- Use caution when resorting to drilling or demolition tools.

Easy Fix for Stripped Screw Heads

If you encounter a partially stripped screw head, there are a few easy fixes you can try before resorting to more drastic measures. These methods can help you remove stripped screws with minimal effort and without damaging the surrounding materials.

Using a Different Size Screwdriver

One simple trick to consider is using a different size screwdriver that fits more securely into the stripped screw head. Sometimes, a slightly larger or smaller screwdriver can provide better grip and leverage, allowing you to turn the screw with ease. Additionally, switching to a flathead screwdriver may also provide better grip on a partially stripped screw head.

Using a Rubber Band

Another effective method for dealing with a stripped screw head is to place a rubber band over the screw head before using a screwdriver. The rubber band increases friction between the screwdriver and the stripped screw, improving grip and making it easier to turn and remove the screw.

These quick and easy fixes can save you time and frustration when dealing with stripped screw heads. Give them a try before moving on to more complex removal methods.

Chemical Solutions for Rusted Screws

When dealing with rusted screws, you can use chemical solutions to help release them. These chemicals work by dissolving the rust or corrosion, making it easier to remove the screw. Here are a few effective chemical solutions that you can use:

- Penetrating Oils: Spraying or pouring penetrating oils, such as Liquid Wrench, over the rusted screw can help loosen the bonds and make it easier to remove. Allow the oil to sit for a few minutes before attempting to turn the screw.

- Oven Cleaner: Applying oven cleaner directly onto the rusted screw can also dissolve the rust and make it easier to remove. Let the cleaner sit for a few minutes before trying to unscrew the screw.

- Soda or Lemon Juice: Pouring soda or lemon juice onto the rusted screw can also be effective in removing the rust. The acidity of these liquids helps to break down the rust, making the screw easier to turn.

Remember to always wear protective gloves and eyewear when working with these chemical solutions. Follow the manufacturer’s instructions and guidelines for each specific product. After applying the chemical solution, give it some time to work its magic before attempting to remove the screw.

Using these chemical solutions can save you time and effort when dealing with rusted screws. However, if the rust is severe or the screw remains stuck, you may need to consider other methods such as drilling or using demolition tools, as mentioned in previous sections.

Now that you are familiar with chemical solutions for rusted screws, let’s move on to Section 9, where we will explore an alternative technique using glue to remove stripped screw heads.

Gluing Tools to Stripped Screw Heads

If a stripped screw cannot be turned with a traditional screwdriver or bit, you can try gluing the tool to the screw head. This method provides a temporary bond between the tool and the screw head, allowing for sufficient grip to remove the stripped screw. Here’s how you can use this technique:

- Apply a small amount of superglue to the screw head.

- Attach the appropriate screwdriver or bit to the screw head.

- Let the glue dry completely, following the manufacturer’s instructions.

- Once the glue has dried, firmly hold the handle of the screwdriver or bit and apply steady pressure while turning counterclockwise.

This method can be especially useful when dealing with small or delicate screws, as it provides a secure grip without damaging the surrounding material. However, it’s important to exercise caution and avoid applying excessive force, as it may cause the screw head to break or strip further.

“Gluing the tool to the stripped screw head can be a handy trick when other methods fail. Just make sure to let the glue dry completely before attempting to remove the screw.”

Remember to choose a glue that is suitable for the materials involved and follow the manufacturer’s instructions for safe and effective use. Additionally, it’s always a good idea to wear protective gloves and eyewear when working with superglue or any other adhesive.

| Pros | Cons |

|---|---|

| Provides a temporary grip for removing stripped screws. | Potential risk of further damaging the screw head. |

| Does not require specialized tools or equipment. | The glue may leave residue on the screw or surrounding material. |

| Works well for small or delicate screws. | May not be effective for severely stripped screws. |

When to Use the Gluing Method

The gluing method is most effective when dealing with stripped screw heads that cannot be turned using traditional methods. It is particularly useful for screws that are small, delicate, or located in tight spaces where other techniques may not be feasible. However, it’s important to note that this method should only be used as a last resort, as there is a risk of further damaging the screw head.

Table 1: Pros and Cons of Gluing Tools to Stripped Screw Heads

Cutting a New Slit in the Screw Head

When a screw head is completely stripped, removing it can seem like an impossible task. However, there is a technique that can help you overcome this frustrating problem. By cutting a new slit in the screw head, you can create a fresh surface to grip onto and successfully remove the stripped screw. This method requires the use of a rotary cutter and a flathead screwdriver or bit.

To cut a new slit in the screw head, start by securing the rotary cutter in place. Position the cutter over the center of the screw head and apply gentle pressure. Slowly rotate the cutter counterclockwise, allowing the sharp blade to slice a small strip across the top of the screw. Be careful not to apply too much force, as this can cause damage to the material surrounding the screw.

Once the new slit is created, select a flathead screwdriver or bit that fits snugly into the slot. Insert it into the newly cut slit and press down firmly. While applying downward pressure, turn the screwdriver or bit counterclockwise to loosen and remove the stripped screw. If necessary, you can use pliers to assist in gripping the screwdriver or bit for added leverage.

By cutting a new slit in the screw head, you can salvage a seemingly irreparable situation. Remember to take your time and exercise caution when using the rotary cutter to avoid any accidents or damage. This method can be a game-changer when it comes to dealing with stubborn stripped screws.

Summary:

- To remove a completely stripped screw, you can cut a new slit in the screw head using a rotary cutter.

- Position the cutter over the center of the screw head and gently rotate it counterclockwise to create a small strip across the top of the screw.

- Insert a flathead screwdriver or bit into the new slit and press down firmly, then turn counterclockwise to loosen and remove the stripped screw.

Remember to exercise caution when using a rotary cutter and to use pliers for added leverage if needed. This method can be a lifesaver when dealing with stubborn stripped screws.

Destroying the Screw with Demolition Tools

If all other methods fail to remove a stubborn screw, you can resort to using demolition tools. This destruction method should only be used as a last resort when all other options have been exhausted. It’s important to proceed with caution and prioritize safety when using demolition tools.

One approach is to use a large drill bit to drill into the screw, essentially destroying it. By applying pressure and turning the drill counterclockwise, you can remove the screw. This method requires a steady hand and precision to avoid damaging surrounding materials.

Another option is to use a bit to remove the screw head, allowing you to pull out the shank with pliers. This method involves drilling into the screw head until it is completely removed. Once the screw head is gone, you can grip the shank with pliers and extract the screw.

It’s worth noting that while demolition tools can be effective in removing stubborn screws, they can also cause damage to the surrounding area. Exercise caution and use protective measures to minimize any potential hazards. If necessary, consult a professional for assistance in utilizing these tools safely.

Table: Pros and Cons of Using Demolition Tools

| Pros | Cons |

|---|---|

| Can remove screws that cannot be extracted by other methods | Potential for damage to surrounding materials |

| Can be effective as a last resort when all other options have failed | Requires caution and precision to avoid accidents |

| May require professional assistance for safe usage |

Conclusion

Removing a broken screw can be frustrating, but with the right techniques, it is possible to successfully extract the broken screw. Whether using a screw extractor, drilling a hole in the screw, or using alternative methods like pliers or gluing tools, there are solutions for every situation. Remember to take precautions and choose the method that best suits your specific needs.

FAQ

How can I remove a broken screw?

To remove a broken screw, you can use methods such as a screw extractor, drilling a hole in the screw, or using pliers to grip the screw shank. These methods are effective for screws with stripped heads, rusted screws, or stuck screws.

How do I use a screw extractor?

Drill a small hole in the center of the broken screw and insert the screw extractor into the hole. Use a wrench to turn the screw extractor counterclockwise and the extractor’s threads will catch onto the screw, allowing you to remove it.

How can I remove a broken screw by drilling a hole?

Start by drilling a small hole in the center of the screw head. Gradually increase the size of the hole until it is large enough to fit a screw extractor or a screwdriver. This method works best for screws with stripped heads or those that cannot be gripped.

Can I use pliers to remove a broken screw?

Yes, if the screw has no head or if the head is completely stripped, you can grip the shank of the screw with pliers as close to the material as possible. Apply firm pressure and turn the pliers counterclockwise to release the screw from the material.

How can I prevent stripped screw heads?

To prevent stripped screw heads, align the screwdriver with the drive of the screw and use a screwdriver that fits properly. Apply even pressure while turning and avoid using power drills that may strip the screw head. Use the appropriate screwdriver type for screws with different shapes to prevent damage.

What can I do to remove rusted or seized screws?

Apply a lubricant or penetrating oil to the rusted screw to help loosen the rust or corrosion. Let the lubricant sit for a few minutes before attempting to remove the screw. The shock & awe method involves tapping the screw with a hammer to break the bonds between the screw and surrounding material.

How can I fix a partially stripped screw head?

Try using a different size screwdriver that fits securely or switch to a flathead screwdriver for better grip. Placing a rubber band over the screw head before using a screwdriver can increase friction and improve grip.

Are there chemicals that can help remove rusted screws?

Yes, you can spray or pour penetrating oils, such as Liquid Wrench, oven cleaner, soda, or lemon juice over the rusted screw to dissolve the bonds and make it easier to remove. Allow the chemical to sit for a few minutes before attempting to remove the screw.

Can I glue tools to stripped screw heads?

Yes, you can apply a small amount of superglue to the stripped screw head and attach a screwdriver or bit. Let the glue dry completely before attempting to remove the screw. The glue creates a temporary bond and provides sufficient grip for removal.

How can I cut a new slit in a stripped screw head?

Use a rotary cutter to slice a small strip across the top of the screw, creating a new slit that can be gripped with a flathead screwdriver or bit. Press down and turn counterclockwise to remove the stripped screw using the new slot created.

What should I do if none of the methods work to remove a broken screw?

If all other methods fail, you can resort to using demolition tools. Use a large drill bit to drill into the screw, essentially destroying it. Alternatively, you can use a bit to remove the screw head, allowing you to pull out the shank with pliers. These methods should only be used as a last resort when all other options have been exhausted.