Are you experiencing trouble starting your vehicle? Testing the starter solenoid is a crucial step in troubleshooting and diagnosing any starting issues. In this guide, we will provide you with a step-by-step process to test the starter solenoid and identify any problems that may be affecting its performance. By following these instructions, you can ensure optimal functioning of your starter solenoid and get your vehicle back on the road in no time.

Key Takeaways:

- Testing the starter solenoid helps diagnose starting issues in your vehicle.

- Understanding the function and operation of the starter solenoid is essential for accurate testing.

- Signs of a faulty starter solenoid include clicking sounds, lack of engagement, or weak clicking sounds.

- Testing methods include click test, multimeter test, continuity test, and voltage drop test.

- Performing these tests will help you troubleshoot and resolve starter solenoid issues.

What is a Starter Solenoid and How Does it Work?

The starter solenoid is a crucial component of a vehicle’s starting system. It acts as a special type of electric relay, responsible for transmitting electric current from the battery to the starter. When you turn the ignition key or press the start button, the starter motor solenoid engages and connects the starter pinion gear to the engine flywheel or flexplate.

The function of the starter solenoid is to complete the electrical circuit between the battery and starter motor. When the solenoid receives the signal to engage, it uses an electromagnetic coil to generate a magnetic field. This magnetic field pulls a plunger or lever, allowing the pinion gear to engage with the flywheel. Once engaged, the starter motor turns the engine, igniting the fuel-air mixture and starting the vehicle.

In summary, the starter solenoid plays a vital role in the starting process of a vehicle. It acts as a bridge between the battery and starter motor, allowing for the controlled engagement of the pinion gear to start the engine. Understanding the operation of the starter solenoid is essential for testing and troubleshooting any issues that may arise.

Table: Common Starter Solenoid Diagnostic Procedures

| Diagnostic Procedure | Description |

|---|---|

| Click Test | Checking for a clicking sound when attempting to start the vehicle. Indicates solenoid engagement. |

| Voltage Test | Measuring the voltage drop from the battery and the solenoid to ensure proper power transfer. |

| Continuity Test | Checking the electrical continuity of the solenoid to detect any faults in the control circuit. |

| Current Test | Testing the current flow through the solenoid to assess its functionality. |

Signs of a Faulty Starter Solenoid

When your vehicle experiences starting issues, one potential culprit could be a faulty starter solenoid. Knowing the signs of a faulty solenoid can help you diagnose and resolve the problem quickly. Here are some common indicators to look out for:

- Clicking sound, no engagement: If you hear a clicking sound when trying to start your vehicle, but the starter does not engage with the engine, it could be a sign of a faulty solenoid. This typically indicates that the solenoid is receiving power, but there is an issue preventing it from connecting the starter to the engine.

- No sound when starting: On the other hand, if you don’t hear any sound at all when attempting to start your vehicle, it may point to a malfunctioning solenoid or a dead car battery. In this case, the solenoid may not be receiving any power at all.

- Weak clicking sound: Sometimes, you may hear a weak clicking sound when trying to start your vehicle. This can indicate that the solenoid is receiving insufficient power to engage the starter properly.

It is important to note that while these signs are commonly associated with a faulty starter solenoid, they can also be caused by other issues such as a dead battery, loose battery cables, corroded battery terminals, or faulty connections in the control or starter circuit. Therefore, it is crucial to perform a thorough diagnosis to accurately determine the root cause of the starting problem.

To ensure the safety of your vehicle and prevent further damage, it is recommended to address any signs of a faulty starter solenoid promptly. In the next section, we will provide you with a step-by-step guide on how to test the starter solenoid to accurately diagnose any problems and determine if the solenoid needs to be repaired or replaced.

Table: Common Signs of a Faulty Starter Solenoid

| Sign | Description |

|---|---|

| Clicking sound, no engagement | Clicking sound when trying to start the vehicle, but the starter does not engage with the engine. |

| No sound when starting | No sound at all when attempting to start the vehicle, indicating a malfunctioning solenoid or a dead car battery. |

| Weak clicking sound | Weaker clicking sound when trying to start the vehicle, indicating insufficient power for the solenoid to engage the starter properly. |

Step-by-Step Guide: How to Test Starter Solenoid

Testing the starter solenoid is an important diagnostic step when troubleshooting starting issues in your vehicle. By following these step-by-step instructions, you can accurately assess the health of your starter solenoid and identify any problems.

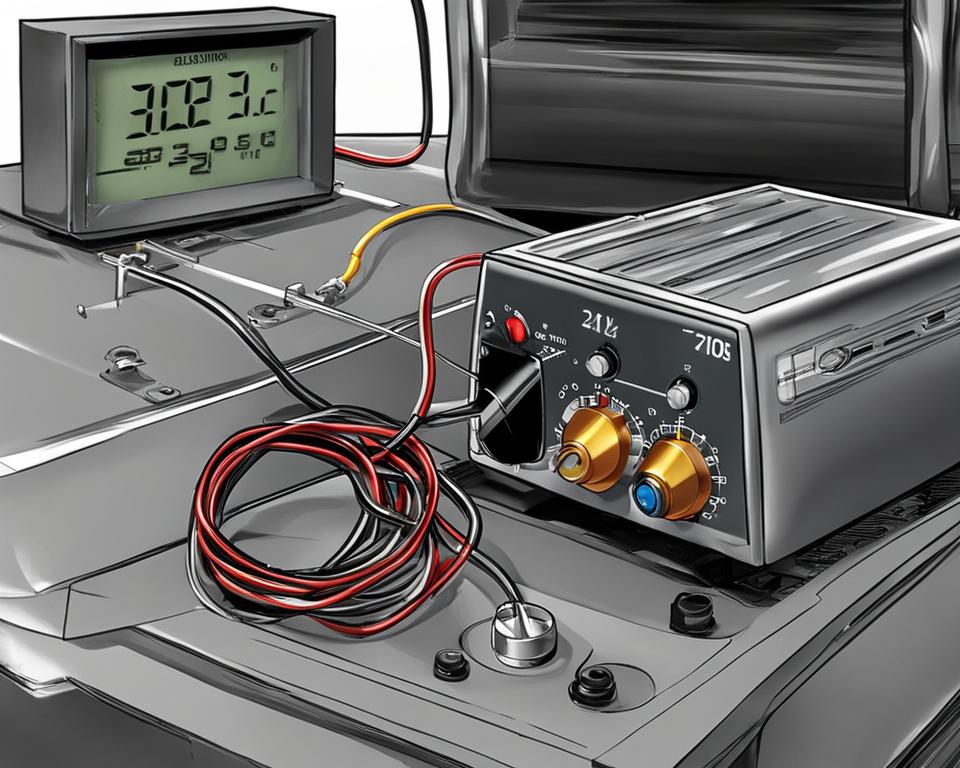

To perform the tests, you will need a set of wrenches and spanners, a voltmeter or multimeter, and a small jumper wire. It is also recommended to have someone assist you by turning the key switch or pressing the start button while you conduct the tests.

The testing process involves four main steps:

- Locating the starter solenoid: Consult your vehicle’s manual to locate the starter solenoid, which is typically found near the battery or the starter motor.

- Conducting a click test and checking the battery: Have your assistant turn on the starter switch while you listen for a clicking sound near the engine. If you hear a click but the starter motor doesn’t move, it indicates insufficient battery power. If there is no sound at all, it suggests a malfunctioning solenoid or a dead battery.

- Testing the current from the solenoid: Use the voltmeter or multimeter to measure the voltage drop from the battery and from the solenoid when it engages. This test helps determine if the solenoid is drawing sufficient power from the battery and can reveal any issues with the solenoid or electrical connections.

- Measuring the voltage drop from the solenoid: Measure the voltage drop across the solenoid terminals while it is engaged. This test helps assess the health of the solenoid and ensures proper power transfer.

By following these steps and conducting the necessary tests, you can accurately diagnose any issues with your starter solenoid and take appropriate measures to resolve them.

Table: Summary of Starter Solenoid Testing Steps

| Testing Step | Description |

|---|---|

| Step 1 | Locate the starter solenoid near the battery or starter motor. |

| Step 2 | Conduct a click test to check if the solenoid engages and battery power is sufficient. |

| Step 3 | Measure the voltage drop from the battery and solenoid to test current draw. |

| Step 4 | Measure the voltage drop across the solenoid terminals to assess solenoid health. |

Using a Click Test to Check Starter Solenoid

One of the initial tests for the starter solenoid is the click test. To perform this test, you will have someone turn on the starter switch while you listen near the engine. If you hear a clicking sound but the starter motor does not move, it indicates that the solenoid is engaging but not receiving enough battery power. If there is no sound at all, it suggests a malfunctioning solenoid or a dead car battery. This test helps you determine if the solenoid is functioning properly or if further analysis is required.

The click test is a simple yet effective way to check the starter solenoid. It provides valuable information about the solenoid’s engagement and power supply. By listening carefully for the clicking sound, you can quickly identify potential issues and narrow down the cause of the starting problem. If the solenoid clicks but the starter motor does not engage, it usually means there is insufficient power reaching the solenoid. This could be due to a weak battery, loose connections, or a faulty solenoid. On the other hand, if there is no sound at all, it indicates a complete failure of the solenoid or a dead battery.

It’s important to note that the click test is just the first step in diagnosing the starter solenoid. While it can provide valuable insights, it is not a definitive test on its own. If you hear a clicking sound, further testing is required to determine the exact cause of the problem. This may involve performing a voltage test, continuity test, or other diagnostic procedures. By following a comprehensive testing process, you can accurately diagnose and resolve any issues with the starter solenoid.

In conclusion, the click test is an essential part of testing the starter solenoid. It helps you determine if the solenoid is engaging and receiving sufficient power. By listening for the clicking sound and interpreting the results, you can gain valuable insights into the health of your starter solenoid. Remember to perform additional tests to further diagnose any issues and ensure optimal performance of your vehicle’s starting system.

Testing Starter Solenoid with Multimeter

One of the most effective methods to test the starter solenoid is by using a multimeter. This diagnostic tool allows you to measure the voltage drop from the battery and the solenoid when it engages, providing valuable insights into the health of the solenoid and its electrical connections.

To begin the test, set your multimeter to the appropriate voltage scale, typically DC volts. Make sure the vehicle is in park or neutral, and the parking brake is engaged for safety. Connect the multimeter’s positive lead to the positive terminal of the battery and the negative lead to the battery’s negative terminal or a suitable ground point.

Next, have a helper turn the key switch or press the start button while you observe the multimeter reading. If the voltage drops significantly, it indicates that the solenoid is drawing sufficient power from the battery. However, if the voltage does not drop or drops too little, it suggests a potential issue with the solenoid or its electrical connections.

Remember to compare your readings with the manufacturer’s specifications for your specific vehicle model. This will help you determine if the starter solenoid is functioning within the acceptable range. If your readings are outside the recommended range, consider further troubleshooting or seeking professional assistance to resolve the issue.

Diagnostic Table: Starter Solenoid Voltage Drop

| Test | Normal Reading | Abnormal Reading | Possible Causes |

|---|---|---|---|

| Voltage Drop from Battery to Solenoid | 0.2V to 0.6V | No voltage drop or inconsistent readings | Loose or corroded battery connections, faulty solenoid |

| Voltage Drop from Solenoid to Starter Motor | Less than 0.5V | High voltage drop or inconsistent readings | Worn starter motor, faulty solenoid, loose or corroded connections |

“Testing the starter solenoid with a multimeter is a quick and efficient way to assess its electrical performance. By measuring the voltage drop, you can identify any issues with the solenoid or its connections. Remember to always prioritize safety and consult your vehicle’s manual for accurate specifications.”

By utilizing a multimeter and following the step-by-step instructions, you can effectively diagnose and troubleshoot any potential problems with your starter solenoid. This testing method allows you to gather accurate readings and make informed decisions about the health of your solenoid. Remember to exercise caution when working with electrical systems in vehicles, and always refer to the manufacturer’s guidelines for the most accurate testing procedures.

Starter Solenoid Continuity Test

One of the essential tests for diagnosing a faulty starter solenoid is the continuity test. This test helps determine if there are any faults in the control circuit or the solenoid itself. By completing the control circuit with a jumper wire, you can check if the solenoid is receiving power and producing a solid clicking sound. If the connections are secure but there is no clicking sound, it indicates a faulty solenoid.

To perform the continuity test, follow these steps:

- Disconnect the battery cables from the battery terminals to ensure safety.

- Locate the starter solenoid. It is typically mounted near the starter motor.

- Identify the control circuit terminals on the solenoid. These are usually labeled “S” and “I” or “S” and “R”.

- Caution: Make sure the transmission is in neutral or park and the parking brake is engaged before proceeding.

- Using a jumper wire, connect the “S” terminal to the positive terminal of the vehicle’s battery.

- Listen for a distinct clicking sound from the solenoid. This indicates that the solenoid is receiving power and the control circuit is functioning correctly.

If you do not hear a clicking sound or if the sound is weak and inconsistent, it suggests a faulty solenoid. In such cases, it is recommended to replace the starter solenoid to ensure proper starting functionality.

Common Issues and Troubleshooting

During the continuity test, if you encounter any issues or if the solenoid fails the test, there are a few potential causes to consider:

- Loose or corroded connections: Check the wiring connections between the solenoid and the battery. Ensure that all connections are tight and free from corrosion.

- Faulty control circuit: If the control circuit is damaged or malfunctioning, it may prevent the solenoid from receiving power. Inspect the wiring and connections for any signs of damage, such as frayed wires or loose terminals.

- Defective solenoid: If all connections and wiring appear to be in good condition, but the solenoid still fails the continuity test, it is likely a faulty solenoid. In this case, replacing the solenoid is recommended.

Summary

The continuity test is a crucial step in troubleshooting a starter solenoid. By completing the control circuit and listening for a clicking sound, you can determine if the solenoid is receiving power and functioning correctly. If the solenoid fails the continuity test, it is important to inspect the connections, wiring, and control circuit for any issues. Ultimately, replacing a faulty solenoid will ensure reliable starting functionality in your vehicle.

Checking Starter Solenoid Voltage Drop

When testing the starter solenoid, it is essential to check the voltage drop to identify any power issues. A voltage drop test helps determine if the solenoid is drawing insufficient power from the battery, which could be causing starting problems in your vehicle. By measuring the voltage drop from the battery and from the solenoid when it engages, you can assess the health of the solenoid and the efficiency of power transfer.

To perform the voltage drop test, you will need a voltmeter or multimeter. Start by setting the meter to the appropriate voltage scale, usually around 20 volts. Connect the positive lead of the meter to the positive terminal of the battery and the negative lead to the positive terminal of the solenoid. With the help of an assistant, have them turn the key switch or press the start button to engage the solenoid while you observe the voltage reading on the meter.

The voltage drop should be within a specific range, typically less than 0.2 volts. If the reading exceeds this range, it indicates a high resistance or a poor connection in the solenoid or its associated wiring. In such cases, further troubleshooting may be required to identify and resolve the issue. It is important to note that the voltage drop test should be performed with caution and in accordance with proper safety measures.

| Test | Voltage Range | Interpretation |

|---|---|---|

| Battery Voltage Drop | Less than 0.2 volts | Healthy |

| Solenoid Voltage Drop | Less than 0.2 volts | Healthy |

| Battery Voltage Drop | 0.2 volts or higher | High resistance or poor connection |

| Solenoid Voltage Drop | 0.2 volts or higher | High resistance or poor connection |

By performing a voltage drop test on the starter solenoid, you can pinpoint any power-related issues and take the necessary steps to troubleshoot and resolve them. Remember to always consult the vehicle’s manual or seek professional assistance if you are unsure about any testing procedures or if further diagnostic work is required.

Conclusion

Testing the starter solenoid is an essential step in troubleshooting any starting issues with your vehicle. By following the step-by-step guide and conducting various tests, you can accurately diagnose and resolve problems with the starter solenoid. Whether you hear clicking sounds or experience a lack of engagement, these signs can indicate a faulty solenoid that needs further analysis. Understanding the function and operation of the starter solenoid is crucial in effectively troubleshooting any issues.

By properly testing the starter solenoid, you can ensure optimal performance and get your vehicle back on the road quickly. Remember to check for signs of a faulty solenoid, such as clicking sounds or a lack of engagement. Utilize the click test, multimeter test, continuity test, and voltage drop test to accurately assess the health of the starter solenoid. By taking these steps, you can diagnose any problems and take the necessary actions to troubleshoot and resolve them.

So, if you’re faced with starting issues in your vehicle, don’t worry. By testing the starter solenoid using the methods outlined in this guide, you can effectively troubleshoot and identify any problems. Follow the step-by-step instructions and listen for the signs. By doing so, you’ll be well on your way to getting your vehicle back up and running smoothly.

FAQ

What is a starter solenoid and how does it work?

The starter solenoid is an electrical device that acts as a special type of electric relay, transmitting electric current from the battery to the starter. When you turn on the ignition key or press the start button, the starter motor solenoid engages and connects the starter pinion gear to the engine flywheel or flexplate.

What are the signs of a faulty starter solenoid?

Signs of a faulty starter solenoid include a clicking sound when trying to start the vehicle but the starter not engaging, a lack of any sound when trying to start the vehicle, or a weak clicking sound. These signs can indicate a malfunctioning solenoid or issues such as a dead battery, loose battery cables, corroded battery terminals, or faulty connections in the control or starter circuit.

How do I test the starter solenoid with a multimeter?

To test the starter solenoid with a multimeter, set the multimeter to the appropriate voltage scale and measure the voltage drop from the battery and from the solenoid when it engages. This test helps determine if the solenoid is drawing sufficient power from the battery and helps identify any issues with the solenoid or electrical connections.

How do I perform a continuity test on the starter solenoid?

To perform a continuity test on the starter solenoid, use a jumper wire to complete the control circuit and determine if the solenoid is receiving power and producing a solid clicking sound. If the connections are secure but there is no clicking sound, it indicates a faulty solenoid.

How do I check the voltage drop on the starter solenoid?

To check the voltage drop on the starter solenoid, measure the voltage drop from the battery and from the solenoid when it engages. This test helps identify any power issues and ensures that the solenoid is drawing sufficient power from the battery. The voltage drop should match a specific range, indicating proper power transfer.