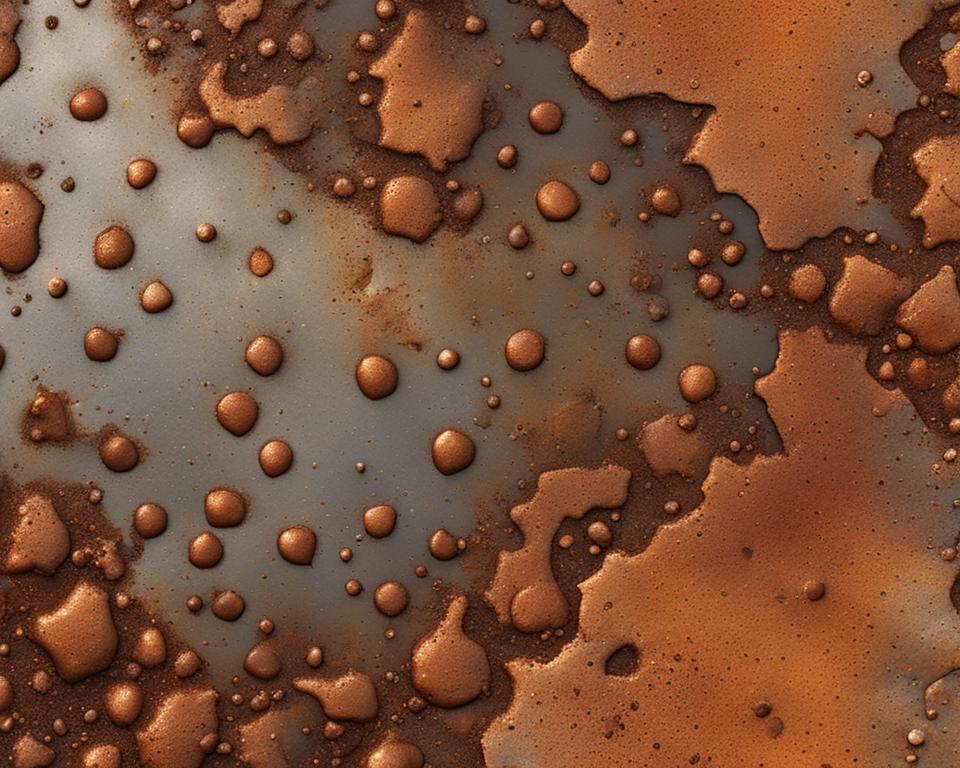

Rust is a common occurrence on metal surfaces and understanding its causes is essential for preventing its formation.

When metal is exposed to moisture and oxygen, a chemical reaction called oxidation occurs, leading to the formation of iron oxide or rust.

This process, known as rusting, can cause structural damage and aesthetic issues if left untreated.

Several factors contribute to rust formation, with moisture and oxygen being the main triggers. Higher humidity levels accelerate rusting, while the amount of oxygen present affects the rate of corrosion.

Additionally, the type of metal plays a role, with iron-containing metals like steel and cast iron being more susceptible to rusting.

The effects of rust on metal surfaces are detrimental. Rust weakens the metal, making it prone to structural failure. It also causes discoloration, giving the metal an unsightly appearance.

Over time, rust can lead to the deterioration of the metal, compromising its integrity and functionality.

- Rust is caused by the corrosion of metal when exposed to moisture and oxygen.

- Moisture and oxygen are the main triggers of rust formation.

- High humidity levels and the amount of oxygen present affect the rate of rusting.

- Iron-containing metals are more susceptible to rusting.

- Rust weakens the metal, causes discoloration, and leads to deterioration.

How Does Rust Form on Metal?

Rust formation on metal surfaces is a result of a chemical process called oxidation. This process occurs when iron reacts with oxygen and water, leading to the formation of iron oxide, commonly known as rust.

Understanding the corrosion mechanisms behind rust formation is essential in preventing its destructive effects on metal.

To comprehend how rust forms, we need to examine the role of moisture and oxygen.

Moisture, including atmospheric humidity, provides the necessary water for the oxidation reaction to take place. Oxygen, on the other hand, acts as a catalyst in the corrosion process.

When metal is exposed to moisture and oxygen, the iron atoms on the surface of the metal react with oxygen molecules to form iron oxide.

This chemical reaction occurs due to the transfer of electrons, resulting in the creation of rust. The presence of iron oxide on the metal’s surface is visible as the characteristic reddish-brown discoloration.

| Required Components for Rust Formation | ||

|---|---|---|

| 1 | Moisture | Water, including atmospheric humidity, provides the necessary medium for the chemical reaction to occur. |

| 2 | Oxygen | The presence of oxygen acts as a catalyst in the corrosion process, facilitating the formation of rust. |

| 3 | Iron | Iron, present in metal surfaces, reacts with oxygen and moisture to initiate the rusting process. |

The formation of rust can be accelerated by environmental factors such as high humidity, as it increases the availability of moisture for the oxidation reaction.

Metallic compounds and impurities on the metal surface can also contribute to the corrosion process. Proper maintenance and protective measures are crucial in preventing rust formation and preserving the integrity of metal structures.

Factors Contributing to Rust Formation

When it comes to rust formation on metal surfaces, several factors come into play. Understanding these factors is essential for effectively preventing rust and maintaining the longevity of metal structures.

Moisture and Oxygen: The Main Rust Triggers

The primary triggers for rust formation are moisture and oxygen. The presence of moisture, such as water or high humidity levels, provides the necessary environment for rust to develop.

When metal is exposed to moisture, a chemical reaction occurs, leading to the formation of rust. Oxygen plays a vital role in this process, acting as a catalyst for the oxidation of metal.

“Moisture and oxygen are the dynamic duo that kickstart the rusting process.”

Influence of Humidity on Rust Formation

Humidity levels play a significant role in the rate of rust formation. Higher humidity levels accelerate the corrosion process, making metal surfaces more susceptible to rusting.

This is why areas with high humidity, such as coastal regions, experience more rapid rust development compared to drier environments.

Type of Metal: How It Affects Rust Formation

The type of metal is another crucial factor in rust formation. Iron-containing metals, such as steel, iron, and cast iron, are more prone to rusting due to their composition.

Other metals, such as aluminum or stainless steel, are naturally more resistant to corrosion and exhibit better rust resistance properties.

By understanding the relationship between moisture, oxygen, humidity, and the type of metal, it becomes clear why rust prevention is essential.

Taking proactive measures to control these factors can significantly extend the lifespan of metal structures and equipment, ensuring their durability and integrity over time.

The Effects of Rust on Metal

Rust can have significant detrimental effects on metal surfaces, compromising their strength, appearance, and overall functionality. Let’s explore the various ways rust impacts metal:

Rust Weakens the Metal

Rust formation weakens the metal, making it more vulnerable to structural failure. As rust consumes the surface of the metal, it corrodes the underlying material, reducing its structural integrity and load-bearing capacity.

This weakness can lead to safety hazards and potential damage to equipment or structures.

Rust Causes Discoloration

One of the most visible effects of rust is the unsightly discoloration it imparts on metal surfaces. As the iron oxide spreads, it creates brown, reddish-brown, or orange stains that mar the appearance of the metal.

This discoloration can be particularly problematic for decorative metalwork, architectural structures, or any surface that requires a clean and appealing look.

Rust Leads to Deterioration

Over time, rust can accelerate the deterioration of metal objects. As the corrosion process continues, it gradually eats away at the metal, causing pitting, holes, or flakes.

This deterioration compromises the overall integrity and functionality of the metal, rendering it unfit for its intended purpose. In severe cases, rust can even cause structural collapse or equipment failure.

“Rust weakens metal, causes discoloration, and leads to its gradual deterioration. It is crucial to address rust issues promptly to maintain the strength, appearance, and functionality of metal surfaces.”

| Effect | Description |

|---|---|

| Weakness | Corrodes the metal, compromising its structural strength and load-bearing capacity. |

| Discoloration | Creates unsightly brown, reddish-brown, or orange stains, diminishing the appearance of the metal. |

| Deterioration | Gradually eats away at the metal, causing pitting, holes, or flaking, and compromising its overall integrity and functionality. |

It is vital to address rust issues promptly to prevent further damage and maintain the strength, appearance, and functionality of metal surfaces.

Rust Prevention Measures

To prevent rust, it is essential to take proactive measures. One effective method is to use a zinc-rich cold galvanizing compound, such as those offered by ZRC.

These coatings create a protective barrier on the metal surface, preventing moisture and oxygen from reaching the metal and triggering rust formation.

By using corrosion prevention coatings, the lifespan of the metal can be significantly extended.

One of the most effective rust prevention measures is the application of a zinc-rich cold galvanizing compound. These coatings provide a durable and long-lasting solution for protecting metal surfaces from corrosion.

The high zinc content in these compounds acts as a sacrificial anode, meaning it corrodes in place of the metal, preventing rust formation.

Additionally, the coatings create a physical barrier that blocks moisture and oxygen from coming into contact with the metal, further inhibiting rust development.

Zinc-rich cold galvanizing compounds, like those manufactured by ZRC, offer several advantages when it comes to rust prevention.

These coatings are easy to apply and adhere well to metal surfaces, ensuring comprehensive coverage and protection. They are also suitable for both interior and exterior applications, making them versatile for various environments.

Coatings containing zinc also provide an aesthetic benefit by offering a smooth and uniform finish. This can enhance the appearance of metal structures and equipment, making them more visually appealing.

In addition to their rust prevention properties, zinc-rich cold galvanizing compounds also provide excellent resistance against other forms of corrosion, extending the overall lifespan of the metal.

The Benefits of Zinc-rich Cold Galvanizing Compound:

- Provides a protective barrier against moisture and oxygen

- Acts as a sacrificial anode, preventing rust formation on the metal surface

- Offers easy application and excellent adhesion

- Suitable for interior and exterior use

- Enhances the appearance of metal structures

- Resists other forms of corrosion

“Using a zinc-rich cold galvanizing compound is a smart investment in rust prevention. These coatings create a protective barrier that shields metal from moisture and oxygen, preventing the onset of rust. With their durability and versatility, they offer long-term protection and contribute to the extended lifespan of metal.”

ZRC Cold Galvanizing Compound for Rust Prevention

ZRC Cold Galvanizing Compound is a zinc-rich compound that provides superior corrosion protection for metal surfaces. With its high percentage of zinc, this compound acts as a powerful shield against rust formation.

It acts as a paint-like coating that adheres firmly to the metal surface, creating a barrier that prevents moisture and oxygen from reaching the metal.

The application of ZRC Cold Galvanizing Compound is versatile, offering flexible options for various projects.

It can be applied using spraying techniques, which provide even coverage and ensure the compound reaches every nook and cranny. Brush-on application is ideal for larger projects, ensuring thorough protection.

This zinc-rich compound forms a self-healing film, continuously protecting the metal surface and repairing any minor damage that may occur over time.

This feature enhances the durability and longevity of the coating, providing extended corrosion prevention.

“ZRC Cold Galvanizing Compound is a game-changer in the field of rust prevention. Its high zinc content and self-healing properties make it the ideal choice for protecting metal surfaces from the damaging effects of corrosion.” – Michael Thompson, Corrosion Specialist

Here is a detailed comparison of the benefits of ZRC Cold Galvanizing Compound:

| Better adherence | Enhanced durability | Self-healing properties |

|---|---|---|

| Adheres tightly to the metal surface, resisting peeling and flaking | Long-lasting protection against rust and corrosion | Repairs minor damage and maintains optimal corrosion prevention |

With its advanced formulation, ZRC Cold Galvanizing Compound offers exceptional resistance to harsh environmental conditions, making it suitable for both indoor and outdoor applications.

It is widely used in industries such as construction, automotive, marine, and manufacturing.

Don’t let rust compromise the integrity of your metal structures. Choose ZRC Cold Galvanizing Compound for reliable and long-lasting corrosion prevention.

Application Options for Rust Prevention

ZRC offers different application options for rust prevention. Whether you’re tackling a large project or need a solution for small, hard-to-reach areas, ZRC has you covered.

Brush-On Rust Prevention

Brush-on rust prevention is the ideal choice for larger projects that require more coverage. With a brush applicator, you can easily apply the rust prevention coating onto the metal surface, ensuring thorough protection.

The brush-on method allows for precise application, making it suitable for various metal structures, equipment, and surfaces.

Get a closer look at brush-on rust prevention in action:

Spray-On Rust Prevention

If you’re looking for convenience and ease of application, especially for smaller projects or hard-to-reach areas, spray-on rust prevention is the way to go.

ZRC offers spray-on rust prevention coatings in aerosol form, allowing for quick and efficient coverage. Alternatively, you can use spray equipment to apply the coating, providing flexibility and versatility in your rust prevention efforts.

Visualize the effectiveness of spray-on rust prevention:

No matter which application method you choose, ZRC’s products are designed to deliver effective corrosion prevention.

Whether you opt for brush-on or spray-on rust prevention, you can trust ZRC to provide long-lasting protection against rust and extend the lifespan of your metal surfaces and structures.

Zinc in Action

Zinc, a crucial component of corrosion prevention coatings like ZRC, plays a vital role in rust prevention. When applied to a metal surface, zinc forms a protective layer that acts as a sacrificial anode.

This means that the zinc corrodes instead of the metal surface, providing effective corrosion protection and preventing further damage from rust and corrosion.

The use of zinc coating as a rust prevention measure is widely recognized for its effectiveness.

By creating a barrier between the metal and the environment, zinc inhibits the contact between moisture, oxygen, and the metal, reducing the chances of rust formation.

When exposed to moisture, zinc undergoes a process known as galvanic corrosion, sacrificing itself to protect the metal it coats.

As the zinc corrodes, it releases ions that inhibit or delay the corrosion of the underlying metal. This sacrificial action effectively prevents rust and extends the lifespan of the metal.

In addition to its sacrificial anode properties, zinc also offers other advantages as a corrosion protection coating.

It has excellent adhesion to metal surfaces, forming a strong bond that withstands exposure to various environmental conditions.

Zinc coatings are also self-healing, meaning that if the coating sustains any minor damages, it can regenerate and continue to provide protection.

The application of zinc coating can be done using various methods such as hot-dip galvanizing, electroplating, or the use of zinc-rich cold galvanizing compounds like ZRC.

These coatings provide durable and long-lasting rust prevention for a wide range of metal structures, equipment, and surfaces.

By utilizing the power of zinc, corrosion and rust can be effectively minimized, ensuring the longevity and functionality of metal components.

With proper maintenance and regular inspections, zinc coatings can provide reliable and cost-effective protection against rust, contributing to the overall durability of metal structures.

HinderRUST: A One-Stop Rustproofing Product

When it comes to protecting metal surfaces from rust and corrosion, HinderRUST is the ultimate solution.

This rustproofing product offers a comprehensive approach to corrosion prevention, acting as a rust inhibitor, preventing further rust formation, and providing long-lasting corrosion protection.

HinderRUST is a solvent-free product that is incredibly easy to use. Its user-friendly application makes it suitable for various purposes, from maintaining metal equipment and vehicles to protecting large structures. With HinderRUST, you can ensure the longevity of your metal assets.

Benefits of HinderRUST:

- Acts as a powerful rust inhibitor, stopping the rusting process in its tracks

- Prevents further rust formation, ensuring long-term protection

- Provides effective corrosion protection, safeguarding metal surfaces from deterioration

- Easy to apply, making it accessible to DIY enthusiasts and professionals alike

- Affordable, offering a cost-effective solution for rust prevention

With its comprehensive rustproofing capabilities, HinderRUST is the go-to product for anyone who wants to keep their metal assets in pristine condition.

By using HinderRUST, you can prevent the costly and time-consuming repairs that come with rusty and corroded metal surfaces.

Testimonials

“HinderRUST has been a game-changer for us. We used to constantly battle rust issues, but since using this product, our equipment has remained rust-free. It’s easy to apply and saves us a ton of money in maintenance costs!”

– John Anderson, Maintenance Supervisor at XYZ Industries

“I was skeptical at first, but HinderRUST exceeded my expectations. It’s amazing how well it prevents rust formation and protects metal surfaces. Now I recommend it to all my colleagues and friends.”

– Sarah Thompson, DIY Enthusiast

Comparison of Rustproofing Products

| Product | Rust Inhibition | Rust Prevention | Corrosion Protection | Application Ease | Price |

|---|---|---|---|---|---|

| HinderRUST | ✓ | ✓ | ✓ | Easy | Affordable |

| Brand X | ✘ | ✘ | ✓ | Difficult | Expensive |

| Brand Y | ✘ | ✓ | ✘ | Moderate | Moderate |

When comparing different rustproofing products, HinderRUST stands out as the most effective solution.

Its ability to inhibit rust, prevent further rust formation, and provide reliable corrosion protection surpasses competitors in the market.

Don’t let rust compromise the integrity of your metal assets. Choose HinderRUST for unmatched rustproofing and corrosion protection, and enjoy the peace of mind that comes with knowing your metal surfaces are well-maintained and long-lasting.

FAQ

What causes rust?

Rust is caused by the corrosion of metal when exposed to moisture and oxygen. This chemical reaction, known as oxidation, leads to the formation of iron oxide or rust on the metal’s surface.

How does rust form on metal?

Rust forms when iron reacts with oxygen and water in a process called oxidation. This chemical reaction results in the formation of iron oxide or rust on the metal’s surface.

What factors contribute to rust formation?

The main triggers for rust formation are moisture and oxygen. Higher humidity levels and the presence of oxygen accelerate the rate of rusting. Additionally, iron-containing metals such as steel, iron, and cast iron are more susceptible to rusting.

What are the effects of rust on metal?

Rust weakens the metal, making it more prone to structural failure. It also causes discoloration, giving the metal an unsightly appearance. Over time, rust can lead to the deterioration of the metal, compromising its integrity and functionality.

What rust prevention measures can be taken?

One effective method is to use a zinc-rich cold galvanizing compound, such as those offered by ZRC. These coatings create a protective barrier on the metal surface, preventing moisture and oxygen from triggering rust formation.

What is ZRC Cold Galvanizing Compound?

ZRC Cold Galvanizing Compound is a zinc-rich compound that provides corrosion protection for metal surfaces. It forms a self-healing film that protects the metal surface and prevents further corrosion.

What application options are available for rust prevention?

ZRC offers brush-on and spray-on rust prevention options. Brush-on rust prevention provides more coverage and is recommended for larger projects, while spray-on rust prevention offers convenience and ease of application for smaller jobs or hard-to-reach areas.

How does zinc help prevent rust?

Zinc, present in corrosion prevention coatings like ZRC, creates a protective layer that acts as a sacrificial anode.

This means that the zinc corrodes instead of the metal surface, preventing further corrosion and protecting the metal from rust and corrosion damage.

What is HinderRUST?

HinderRUST is a rustproofing product that acts as a rust inhibitor, prevents further rust formation, and provides corrosion protection.

It is easy to use and affordable, making it an ideal choice for maintaining and protecting metal equipment, vehicles, and structures.

How can rust be prevented?

By taking proactive steps such as using corrosion prevention coatings and rustproofing products like HinderRUST, the integrity and functionality of metal can be preserved, extending its lifespan.

Conclusion

When it comes to metal surfaces, rust formation is a common problem that can have serious consequences. Structural damage and unsightly appearance are just a few of the issues that can arise from rust.

However, by understanding the root causes of rust, we can implement effective prevention measures to control and combat this corrosion.

One of the key factors in rust prevention is moisture control. Moisture provides the essential element for rust formation. By keeping metal surfaces dry, we can significantly reduce the risk of rust development.

Additionally, oxygen plays a crucial role in the rusting process. By minimizing exposure to oxygen, either through protective coatings or rustproofing products, we can further prevent the formation of rust.

Corrosion prevention coatings, such as zinc-rich compounds, offer a powerful solution for rust prevention. These coatings create a protective barrier that shields metal surfaces from moisture and oxygen, crucial factors in rust formation.

Products like HinderRUST provide an all-in-one solution for corrosion control, acting as rust inhibitors and corrosion protectors.

In conclusion, by taking proactive steps to prevent rust, we can extend the lifespan of metal structures and equipment.

Through the use of corrosion prevention coatings and rustproofing products, we can preserve the functionality and integrity of metal surfaces for longer periods.

Rust prevention and corrosion control are essential for maintaining the quality and durability of metal, ensuring its continued use and aesthetic appeal.

![Ray Dalio Quotes [Principles, Life, Investment]](https://tagvault.org/wp-content/uploads/2023/04/Screen-Shot-2023-04-19-at-7.57.49-PM.png)