Welcome to our article series on engine components! In this installment, we will delve into the fascinating world of carburetors. Have you ever wondered how a carburetor works and its role in the functioning of an engine? Well, you’re in the right place! In this article, we will explore the working principle of a carburetor, its basics, and its operation.

But first, let’s take a moment to appreciate the complexity of the carburetor. It is a crucial component in a gasoline internal combustion engine, responsible for controlling and mixing the air and fuel entering the engine. By understanding how it works, we gain insight into fuel efficiency, engine performance, and even maintenance requirements.

So, let’s dive in and explore the inner workings of a carburetor. From Bernoulli’s principle to the various components that make up this intricate device, we’ll cover it all. By the end of this article, you’ll have a solid understanding of how a carburetor operates and its significance in a well-performing engine.

Key Takeaways:

- A carburetor is an essential device that controls and mixes air and fuel in a gasoline internal combustion engine.

- It works on Bernoulli’s principle, where airflow and pressure differentials draw fuel into the airstream.

- The carburetor consists of various components, including the float chamber, choke valve, throttle valve, main jet, and venturi, which work together to regulate the fuel and air mixture.

- Understanding the functioning and maintenance of a carburetor is crucial for optimal engine performance and fuel efficiency.

- Regular maintenance, cleaning, and proper use of features like carb heat and accelerator pump help ensure smooth engine operation.

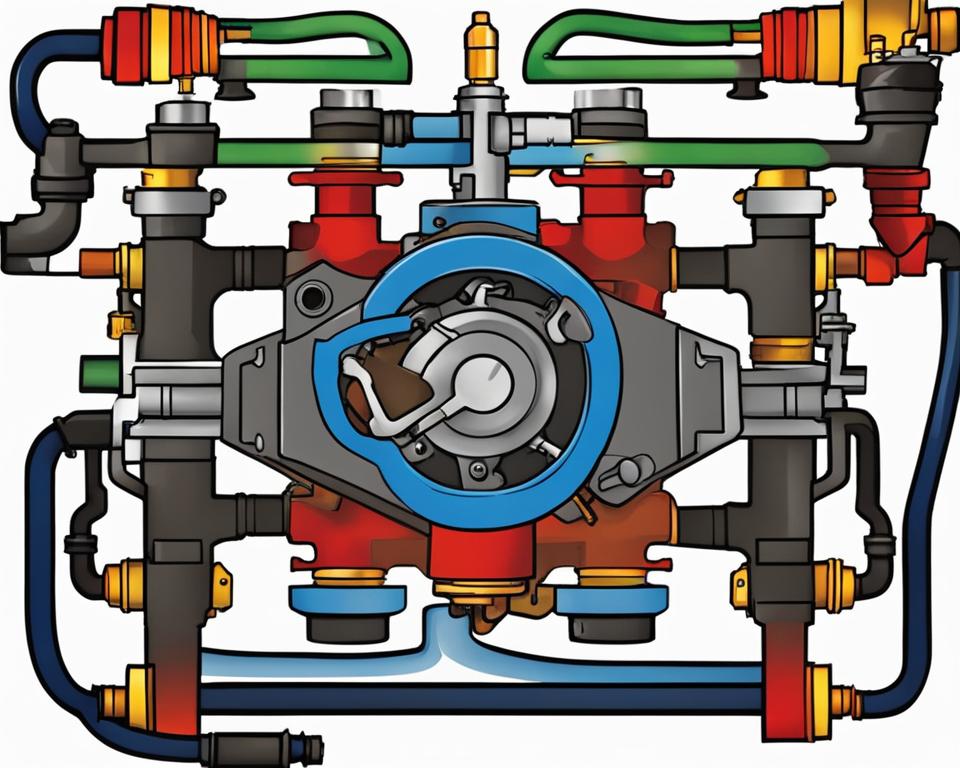

Carburetor Components and Their Functions

In order to understand how a carburetor works, it is important to know about its various components and their functions. Each component plays a crucial role in regulating the fuel and air mixture that enters the engine cylinder. Let’s take a closer look at the key components of a carburetor:

Float Chamber:

The float chamber, also known as the combustion chamber, acts as a reservoir for fuel combustion. It automatically regulates the fuel valve, ensuring a constant supply of fuel to the carburetor.

Floater:

The floater helps maintain fuel stability in both high and low fuel conditions. It adjusts the fuel level in the float chamber to prevent overflow or fuel shortage.

Choke Valve:

The choke valve enriches the fuel mixture for easy starting and smooth daily activities. It reduces the airflow, increasing the fuel-to-air ratio, particularly in cold engine conditions.

Throttle Valve:

The throttle valve regulates the level of air mixture entering the combustion chamber. By controlling the airflow, it determines the engine’s power output and speed.

Main Jet:

The main jet regulates the amount of fuel mixed with clean air. It ensures a proper fuel and air mixture ratio for efficient combustion and optimal engine performance.

Jet Needle, Slow Jet, Pilot Screw:

These components work together to support the stable performance of the carburetor. The jet needle controls the fuel flow at different throttle positions, while the slow jet and pilot screw fine-tune the fuel mixture for low-speed and idle conditions.

Main Nozzle:

The main nozzle acts as the main transmitter of fuel inside the carburetor. It delivers the fuel efficiently to the combustion chamber, ensuring consistent fuel supply for smooth engine operation.

Venturi:

The venturi is responsible for increasing the speed of airflow, improving the car’s speed and performance. It creates a pressure difference that draws more fuel into the airstream, maintaining the ideal fuel-to-air ratio.

Understanding the functions of these carburetor components is essential in ensuring the proper functioning and maintenance of the carburetor system. By maintaining these components, you can optimize your engine’s performance and fuel efficiency.

Carburetor Function and Working Principle

The carburetor plays a crucial role in the functioning of an internal combustion engine by controlling the fuel and air mixture that enters the engine cylinder. Its main function is to regulate the flow of fuel and combine it with the appropriate amount of air to ensure efficient combustion. This process is essential for the engine’s overall performance and fuel efficiency.

The working principle of a carburetor is based on Bernoulli’s principle. As air flows through the carburetor, its velocity increases, reducing the static pressure. This decrease in pressure draws fuel from the carburetor’s reservoir and into the airstream. The fuel and air mixture is then delivered to the engine cylinder for combustion, producing the power needed to propel the vehicle.

The carburetor comprises various components that work together to control the fuel and air mixture. These components include the float chamber, throttle valve, main jet, jet needle, and venturi. The float chamber stores the fuel and regulates its level, while the throttle valve controls the amount of air entering the carburetor. The main jet and jet needle control the amount of fuel delivered based on the airflow, ensuring the optimal mixture for combustion. The venturi increases the speed of airflow, improving the engine’s performance.

Overall, understanding the function and working principle of a carburetor is essential for maintaining a well-performing engine. By ensuring the proper fuel and air mixture, the carburetor plays a significant role in optimizing fuel efficiency and engine performance.

Summary:

- The carburetor regulates the fuel and air mixture that enters the engine cylinder.

- It works on Bernoulli’s principle, where the airflow reduces the pressure and draws fuel into the airstream.

- The carburetor consists of components such as the float chamber, throttle valve, main jet, jet needle, and venturi.

- Understanding the function and working principle of a carburetor is crucial for maintaining optimal engine performance and fuel efficiency.

How the Carburetor Works in a Car

The carburetor is a key component of the fuel and air supply system in a car’s engine. It plays a vital role in ensuring the proper functioning of the engine by regulating the flow of fuel and air mixture. The carburetor operates based on the movement of the piston in the engine. As the piston moves back and forth, the carburetor system draws in air and fuel from the front, where they are mixed together.

Once the air and fuel mixture is created, it is ignited by a spark plug, resulting in combustion in the engine cylinder. This combustion process generates the power needed to drive the vehicle forward. The carburetor system works synchronously to ensure the accurate intake of fuel and air, facilitating optimal engine performance.

To visualize the operation of a carburetor system in a car, imagine a well-orchestrated dance between the piston, airflow, and fuel supply. As the piston moves, the carburetor system adjusts the fuel and air mixture according to the engine’s requirements, delivering the right amount of power for efficient operation.

| Carburetor Operation in Cars | |

|---|---|

| Piston Movement | The piston moves back and forth, creating the suction necessary for drawing in fuel and air. |

| Fuel Ignition | The air and fuel mixture is ignited by a spark plug, leading to combustion in the engine cylinder. |

| Carburetor System | The carburetor system regulates the flow of fuel and air mixture, ensuring optimal engine performance. |

In summary, the carburetor system in a car works by utilizing the movement of the piston to draw in fuel and air. This mixture is then ignited to generate power for the engine. By understanding how the carburetor operates, drivers can appreciate the importance of this component in maintaining smooth and efficient car performance.

Carburetor Maintenance and Care

Regular maintenance is crucial for the proper functioning of a carburetor. By performing routine maintenance tasks, you can ensure that your carburetor continues to operate at its best and avoid potential issues. Here are some important maintenance steps to keep your carburetor in top shape:

- Cleaning the Carburetor Filter: The carburetor filter is responsible for keeping dirt and debris out of the fuel system. Over time, it can become clogged and affect the carburetor’s performance. Regularly remove and clean the carburetor filter using an air compressor or by washing it thoroughly if it’s made of foam. This simple task will help ensure proper fuel flow and prevent blockages.

- Cleaning Carburetor Components: It’s essential to clean the various components of the carburetor to remove any buildup or residue that can affect its operation. Carefully remove components such as the float needle, pilot jet, main jet, and carburetor bowl. Use a soft brush and air pressure to clean these parts thoroughly. By doing so, you’ll maintain optimal fuel-air mixture and prevent performance issues.

- Performing Routine Maintenance: In addition to cleaning the filter and carburetor components, make sure to perform routine maintenance tasks such as checking and adjusting the float level, inspecting fuel lines for leaks or damage, and ensuring all connections are secure. These simple maintenance tasks can help prevent major issues and keep your carburetor running smoothly.

By following these maintenance tips, you can ensure the longevity and optimal performance of your carburetor. Regular cleaning and routine maintenance will help prevent clogs, improve fuel efficiency, and maintain smooth engine operation. Take care of your carburetor, and it will take care of your engine.

Table: Maintenance Tasks for Carburetor

| Maintenance Task | Description |

|---|---|

| Cleaning the Carburetor Filter | Remove and clean the carburetor filter to prevent blockages and ensure proper fuel flow. |

| Cleaning Carburetor Components | Thoroughly clean components such as float needle, pilot jet, main jet, and carburetor bowl to remove buildup and residue. |

| Performing Routine Maintenance | Check and adjust float level, inspect fuel lines, and ensure all connections are secure. |

Regular maintenance is the key to keeping your carburetor in optimal condition. By following these maintenance tasks, you can prevent issues, improve performance, and ensure the smooth operation of your engine.

Understanding Carburetor Ice and Carb Heat

Carburetor ice is a common phenomenon that can occur in certain conditions. When the throttle valve is close to a point where the velocity of the mixture increases but the temperature decreases, carburetor ice can form. This can lead to a reduction in engine power and potentially dangerous situations. To prevent carburetor ice from forming, it is important to understand and utilize carburetor heat properly.

Carburetor heat is a feature in carburetor systems that helps prevent carburetor ice from forming. When leaving the green arc, turning on the carburetor heat is recommended. Carb heat provides hot air to melt any ice in the carburetor and prevents ice from blocking the induction system. However, it’s important to note that improper use of carb heat can lead to partial carburetor icing. This occurs when the ice melts and refreezes upon contact with the cold metal of the throttle plate.

Some aircraft are equipped with a carburetor temperature gauge, which allows pilots to monitor the temperature of the carburetor. This gauge helps pilots determine the appropriate use of carburetor heat based on the current conditions. It’s important to follow the manufacturer’s instructions and operating procedures to ensure the safe and effective use of carburetor heat.

“Carburetor ice can have a significant impact on engine performance and safety. Understanding the operation of carb heat and being aware of carburetor ice formation is crucial for pilots to maintain control and prevent potential issues.” – Aviation Expert

By understanding carburetor ice and carb heat, pilots can take the necessary precautions to prevent carburetor ice from forming and ensure the safe operation of their aircraft.

| Carburetor Ice | Carb Heat | Carburetor Temperature Gauge |

|---|---|---|

| Ice formation in the carburetor | Feature to prevent carburetor ice | Monitors carburetor temperature |

| Reduces engine power | Provides hot air to melt ice | Aids in determining carb heat usage |

| Potential safety hazard | Improper use can cause partial icing | Helps pilots make informed decisions |

The Importance of an Accelerator Pump

In the carburetor system, the accelerator pump plays a vital role in providing an additional fuel supply during heavy acceleration. When you push the throttle suddenly for full power, the accelerator pump squirts a small amount of fuel into the carburetor throat. This ensures a smooth engine operation under increased load and improves throttle response. The accelerator pump helps maintain fuel flow during acceleration, preventing any hesitation or lag in engine performance.

“The accelerator pump is like a power boost button for your engine. It delivers that extra burst of fuel needed when you demand quick acceleration.”

Starting an engine with an accelerator pump is also beneficial, especially for cold starts. By pumping the throttle three times before starting the engine, you prime the engine with extra fuel from the accelerator pump. This aids in starting a cold engine and ensures a smooth ignition process. The accelerator pump is a valuable feature in a carburetor system, enhancing the overall driving experience and providing the necessary fuel supply during acceleration.

| Accelerator Pump Benefits | Accelerator Pump Operation |

|---|---|

| Improves throttle response | Squirts additional fuel during acceleration |

| Prevents hesitation or lag in engine performance | Activates when the throttle is pushed suddenly |

| Aids in starting a cold engine | Primes the engine with extra fuel |

Whether you’re looking for better throttle response or a smooth start in cold weather, the accelerator pump is a crucial component in the carburetor system. Its ability to supply extra fuel during acceleration ensures optimal engine performance and enhances your driving experience. So the next time you hit the throttle, remember the accelerator pump is there, providing that quick burst of fuel when you need it most.

Carburetor Fuel Supply and Float Chamber

The fuel supply system of a carburetor relies on the efficient functioning of the float chamber to ensure a continuous and reliable fuel supply to the engine. The float chamber acts as a fuel reservoir, maintaining a safe and consistent fuel level inside the carburetor. This fuel level is regulated by a floating inlet valve, which prevents overflow or fuel shortage. The fuel is delivered to the float chamber through a fuel pump, ensuring that the engine always has an adequate fuel supply for optimal performance.

The float chamber and its fuel level regulation play a critical role in the proper operation of the carburetor. If the fuel level is too high, it can result in flooding, causing an overly rich fuel mixture and poor engine performance. On the other hand, if the fuel level is too low, it can lead to fuel starvation, resulting in a lean mixture and potential engine damage. Therefore, maintaining the correct fuel level in the float chamber is essential for the carburetor to function optimally.

Table: Carburetor Fuel Supply and Float Chamber

| Carburetor Component | Function |

|---|---|

| Float Chamber | Acts as a fuel reservoir and maintains a consistent fuel level |

| Floating Inlet Valve | Regulates the fuel level in the float chamber to prevent overflow or fuel shortage |

| Fuel Pump | Delivers fuel to the float chamber for a continuous and reliable fuel supply |

By ensuring that the float chamber is properly maintained and the fuel level is regulated correctly, the carburetor can provide a consistent and reliable fuel supply to the engine, ensuring optimal performance and fuel efficiency.

The Role of Power Valve and Metering Rod

In a four-stroke engine, the power valve and metering rod play a crucial role in ensuring optimal fuel supply at high loads. The power valve, a spring-loaded valve, opens when the airflow through the carburetor increases, allowing for the addition of extra fuel to the main metering circuit. This additional fuel supply is necessary to meet the increased demand for power and prevent engine knocking.

The metering rod system is an alternative mechanism that also provides additional fuel at high loads. It works by increasing the volume of fuel flow through the jet, ensuring adequate fuel supply to support increased engine performance. The combined action of the power valve and metering rod allows the engine to receive the required fuel supply for enhanced power output and a smoother running experience.

“The power valve and metering rod are critical components in the carburetor system, ensuring that the engine receives the necessary fuel for optimal performance under high load conditions.” – Automotive Expert

By delivering additional fuel to the engine cylinder, the power valve and metering rod help maintain fuel efficiency and prevent engine damage. These components are designed to work in tandem with other carburetor systems, such as the main jet and idle circuit, to ensure a consistent and reliable fuel supply throughout different operating conditions.

| Component | Function |

|---|---|

| Power Valve | Opens to increase fuel flow at high loads |

| Metering Rod | Increases volume of fuel flow through the jet at high loads |

The power valve and metering rod are essential components that contribute to the overall performance and efficiency of a carbureted engine. Understanding their role in controlling fuel supply during high loads is key to optimizing engine power and preventing potential issues that can arise from fuel starvation or improper fuel mixture.

The Role of the Idle Circuit and Off-Idle Circuit

In a carburetor, the idle circuit and off-idle circuit play important roles in ensuring smooth engine operation and responsive throttle control. The idle circuit is responsible for fuel metering when the engine is running at low rpm, while the off-idle circuit provides additional fuel as the throttle is opened, ensuring a smooth transition from idle to higher speeds.

Idle Circuit

The idle circuit operates when the engine is running at idle or low rpm. It is activated by vacuum under the throttle plate and controls the flow of fuel through the idle jet. The idle circuit ensures that the engine receives the right amount of fuel for stable operation at low speeds. This is important for maintaining a smooth and steady idle, as well as providing adequate fuel for various accessories, such as power steering and air conditioning, that may be drawing from the engine at idle.

Off-Idle Circuit

The off-idle circuit comes into play as the throttle is opened from idle. Its purpose is to provide additional fuel to compensate for the increased airflow and ensure a smooth transition from idle to higher speeds. When the throttle is opened, the off-idle circuit delivers a controlled amount of fuel through the off-idle jet, allowing for responsive throttle response and preventing any hesitation or stumble during acceleration. By delivering the right amount of fuel at the right time, the off-idle circuit ensures a seamless transition and optimal engine performance.

Both the idle circuit and off-idle circuit are crucial for maintaining proper low-speed fuel metering and smooth throttle response. By precisely regulating the fuel flow during idle and off-idle conditions, these circuits contribute to overall engine efficiency and performance. Proper maintenance and adjustment of these circuits are important to ensure optimal fuel metering and smooth engine operation throughout the entire RPM range.

Table: Comparison of Idle Circuit and Off-Idle Circuit

| Idle Circuit | Off-Idle Circuit |

|---|---|

| Operates at low engine speeds | Operates as the throttle is opened from idle |

| Controls fuel flow through the idle jet | Delivers additional fuel through the off-idle jet |

| Ensures stable idle and provides fuel for accessories | Facilitates a smooth transition from idle to higher speeds |

| Affects low-speed fuel metering | Affects throttle response and acceleration |

Conclusion

The carburetor plays a crucial role in the fuel and air supply system of an engine, impacting its overall performance. By regulating the mixture of fuel and air that enters the engine cylinder, the carburetor ensures efficient fuel combustion, leading to optimal engine performance. It is essential to understand the functioning and maintenance of this vital component to keep your engine running smoothly.

Regular maintenance is key to the proper functioning of the carburetor. By cleaning the carburetor filter and components, such as the float needle, pilot jet, and carburetor bowl, you can prevent any issues and maintain the stability of the carburetor’s performance. Routine maintenance should be performed regularly to ensure a continuous and reliable fuel supply for your engine’s optimal performance.

Remember to utilize the features that your carburetor offers, such as carb heat and accelerator pump. Carb heat helps prevent carburetor ice formation, while the accelerator pump provides additional fuel during heavy acceleration for smooth engine operation. By taking care of your carburetor and understanding its importance, you can enjoy high-performance and fuel-efficient driving.

FAQ

How does a carburetor work?

A carburetor is a device that controls and mixes air and fuel entering a gasoline internal combustion engine. It works on Bernoulli’s principle, where the static pressure of the intake air reduces at higher speeds, drawing more fuel into the airstream. The carburetor ensures efficient fuel combustion and improved fuel efficiency.

What are the components of a carburetor and their functions?

The components of a carburetor include the float chamber, floater, choke valve, throttle valve, main jet, jet needle, slow jet, pilot screw, main nozzle, and venturi. These components work together to regulate the amount of fuel and air mixture that enters the engine cylinder, ensuring efficient fuel combustion.

What is the function and working principle of a carburetor?

The primary function of a carburetor is to adjust the amount of fuel and air mixture that enters the engine cylinder. It works on Bernoulli’s principle, where the airflow through the carburetor increases velocity and reduces pressure, drawing more fuel into the airstream. This mixture of fuel and air is combusted in the engine cylinder, producing power.

How does the carburetor work in a car?

In a car, the carburetor system utilizes the movement of the piston. When the car engine is turned on, the piston moves back and forth, sucking air and fuel from the front and mixing them. The mixture is then ignited by a spark plug, causing combustion in the engine cylinder. The carburetor system ensures the proper intake of fuel and air, resulting in optimal engine performance.

What maintenance does a carburetor require?

Regular maintenance is essential for the proper functioning of a carburetor. Cleaning the carburetor filter and components, such as the float needle, pilot jet, and main jet, helps ensure stable performance. Routine maintenance should be done regularly to prevent any issues and maintain optimal engine performance.

How does carburetor ice and carb heat work?

Carburetor ice can form in certain conditions, and using carb heat helps prevent it. Carb heat provides hot air to melt any ice in the carburetor, preventing ice from blocking the induction system. Proper use of carb heat and understanding carburetor ice formation is important to maintain engine performance and prevent issues.

What is the role of an accelerator pump in a carburetor?

The accelerator pump provides an additional momentary fuel supply during heavy acceleration. It squirts a small amount of fuel into the carburetor throat to ensure smooth engine operation under increased load. Priming the engine with extra fuel from the accelerator pump helps in starting a cold engine.

How does the carburetor ensure a constant fuel supply?

The carburetor ensures a constant supply of fuel through the float chamber. The floating inlet valve regulates the fuel level, preventing overflow or fuel shortage. A fuel pump delivers fuel to the float chamber, and the floating device maintains a safe level of fuel inside the carburetor, ensuring continuous and reliable fuel supply for optimal engine performance.

What is the role of a power valve and metering rod in a carburetor?

In a four-stroke engine, the power valve and metering rod provide extra fuel at high loads. The power valve opens when the airflow through the carburetor increases, allowing more fuel into the main metering circuit. The metering rod system increases the volume of fuel flow through the jet, supplying additional fuel at high loads, resulting in increased power output and reduced engine knocking.

What is the role of the idle circuit and off-idle circuit in a carburetor?

The idle circuit meters fuel when the engine is running at low rpm. It is activated by vacuum under the throttle plate and regulates the flow of fuel through the idle jet. The off-idle circuit provides additional fuel as the throttle starts to open, ensuring a smooth transition from the idle circuit to the main metering circuit, maintaining smooth throttle response and fuel metering at different engine speeds.